Product Description

DLSS supplies ASTM B111 C44300 (O61) seamless tubes in size 22 mm OD × 1 mm wall thickness × 2010 mm length, manufactured from Admiralty Brass (C44300). This copper-zinc alloy with a small addition of tin provides excellent resistance to seawater corrosion, dezincification, and erosion, making it one of the most widely used brass tubes for heat exchangers and condensers.

The tubes are delivered in O61 annealed condition, ensuring good ductility and workability. Specifically designed for air cooled condenser applications, Admiralty Brass tubes combine high thermal conductivity with durability in demanding industrial cooling systems.

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B111 |

| Material | C44300 Admiralty Brass (Copper-Zinc-Tin Alloy) |

| Condition | O61 (Annealed) |

| Type | Seamless Tube |

| Size | 22 mm OD × 1 mm WT × 2010 mm Length |

| Corrosion Resistance | Excellent resistance to seawater, brackish water, and polluted cooling waters |

| Applications | Air cooled condensers, heat exchangers, power plants, petrochemical systems |

Key Features

-

Admiralty Brass Alloy (C44300): Outstanding dezincification resistance and long service life.

-

High Thermal Conductivity: Ensures efficient heat transfer in air cooled condensers.

-

O61 Annealed Condition: Provides ductility and ease of fabrication into bundles or coils.

-

Corrosion Resistance: Performs well in fresh water, brackish water, and seawater environments.

-

Seamless Tube: High strength and reliability in demanding cooling applications.

Applications

-

Air Cooled Condensers – efficient thermal performance with long durability.

-

Heat Exchangers – used in petrochemical, refinery, and industrial cooling systems.

-

Power Plant Cooling Systems – reliable operation with seawater and brackish water.

-

Marine Engineering – condenser and cooler tubes in ships.

-

Desalination Equipment – resistant to saline and brine solutions.

Why Choose DLSS Admiralty Brass Tubes?

-

Wide range of brass and copper alloy tubes (C44300, C68700, C70600, etc.).

-

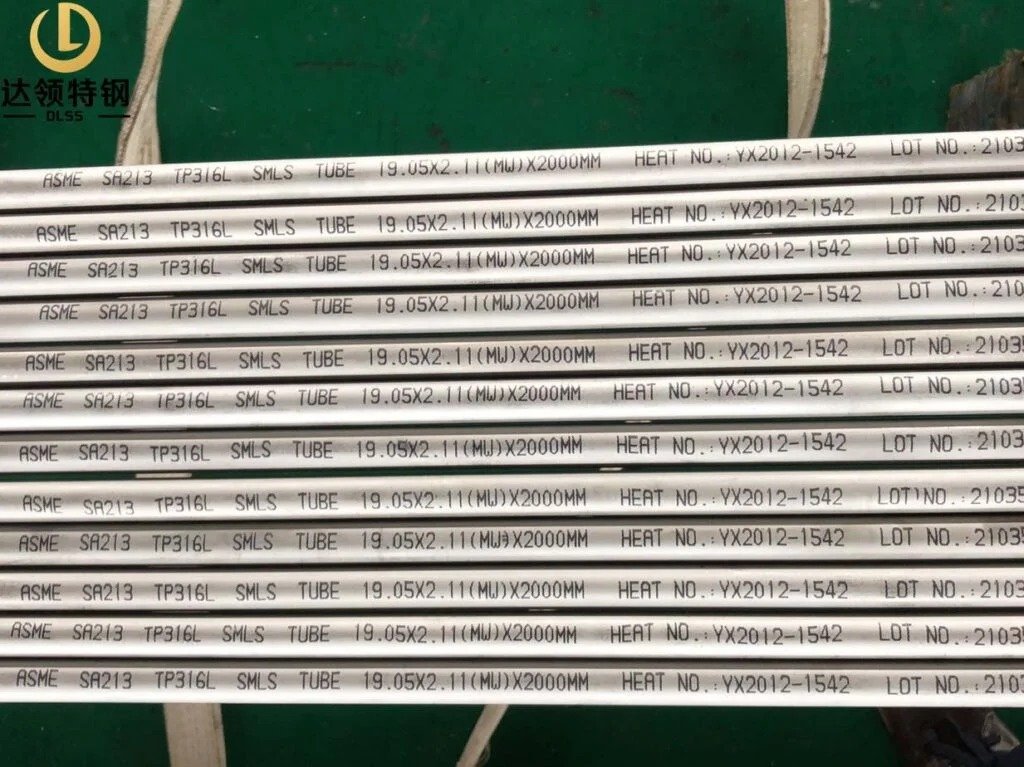

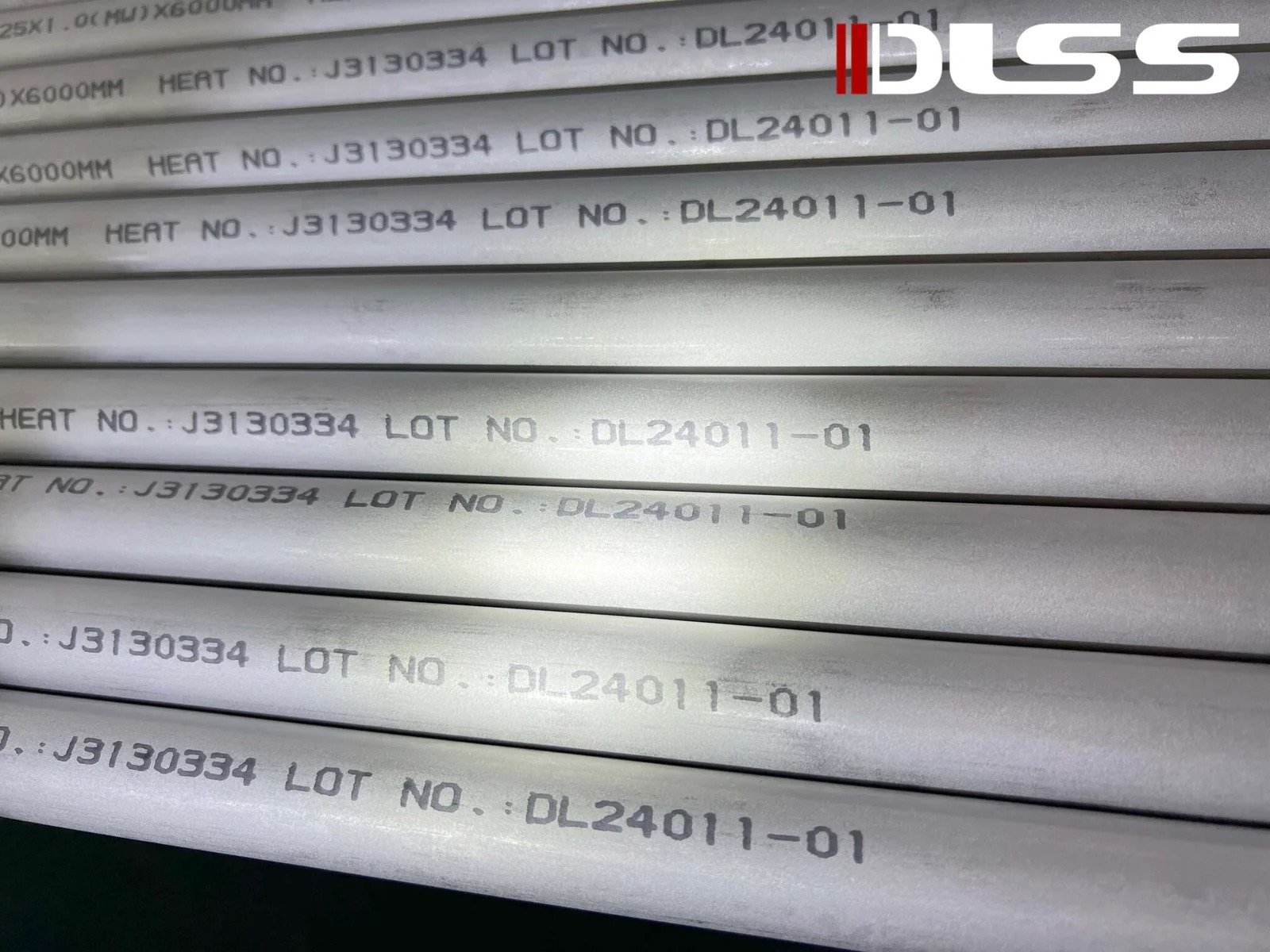

Strict quality control with Mill Test Certificates EN 10204/3.1.

-

Third-party inspections (SGS, BV, TUV) available upon request.

-

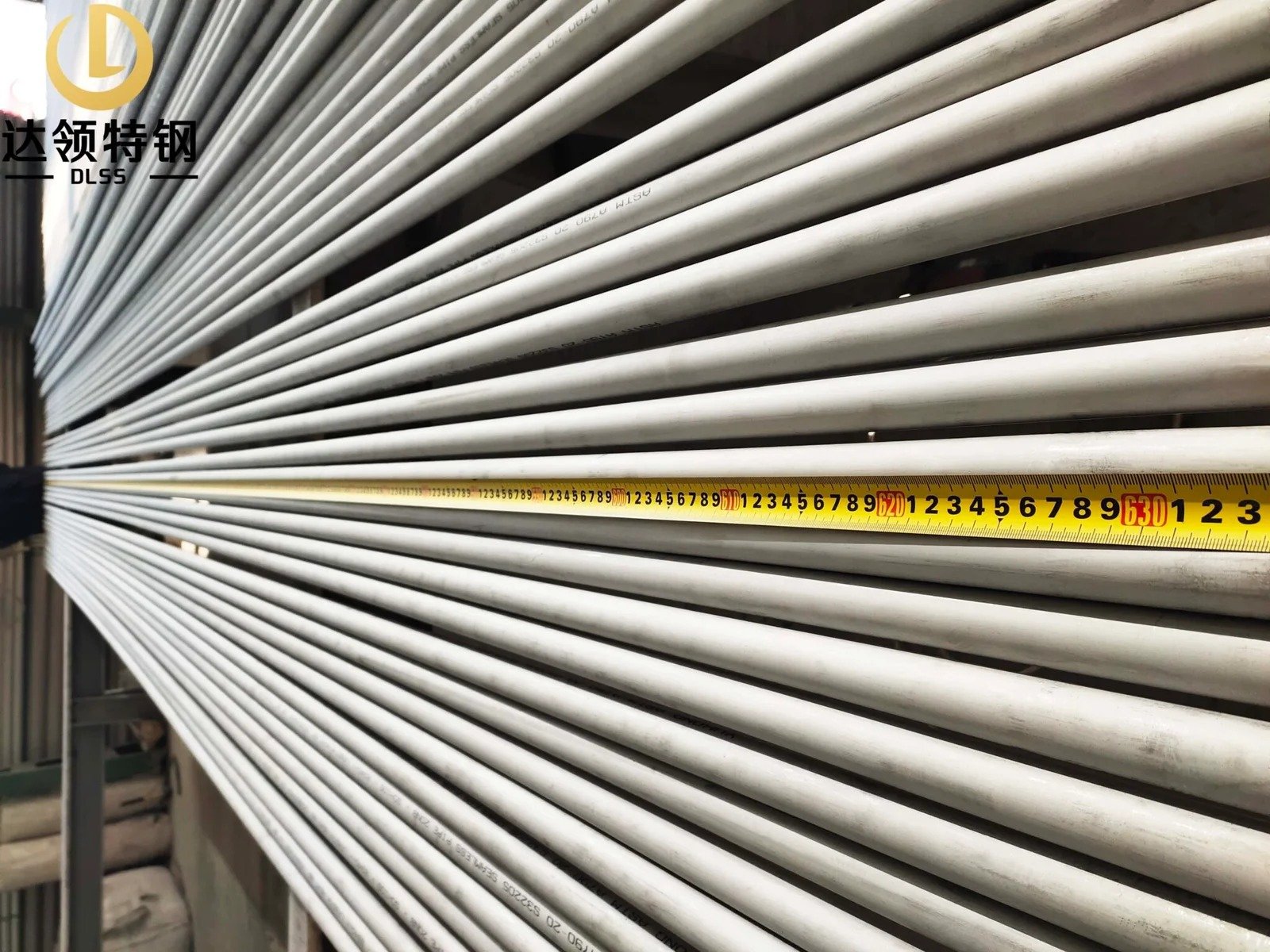

Export packaging – tubes capped, plastic wrapped, seaworthy wooden cases.

-

Proven project experience – global supply for condensers and cooling equipment.

Frequently Asked Questions (FAQ)

Q1: Why is Admiralty Brass C44300 used in condensers?

A1: Because it has excellent resistance to dezincification, high thermal conductivity, and seawater durability.

Q2: What does O61 mean?

A2: O61 refers to the annealed condition, improving ductility and ease of fabrication.

Q3: Can these tubes be used in both water cooled and air cooled condensers?

A3: Yes, Admiralty Brass tubes are suitable for both, but air cooled condensers benefit from their high thermal conductivity.

Q4: Do you provide U-bend tubes?

A4: Yes, DLSS supplies straight tubes, U-bent tubes, and cut-to-length options.