Introduction

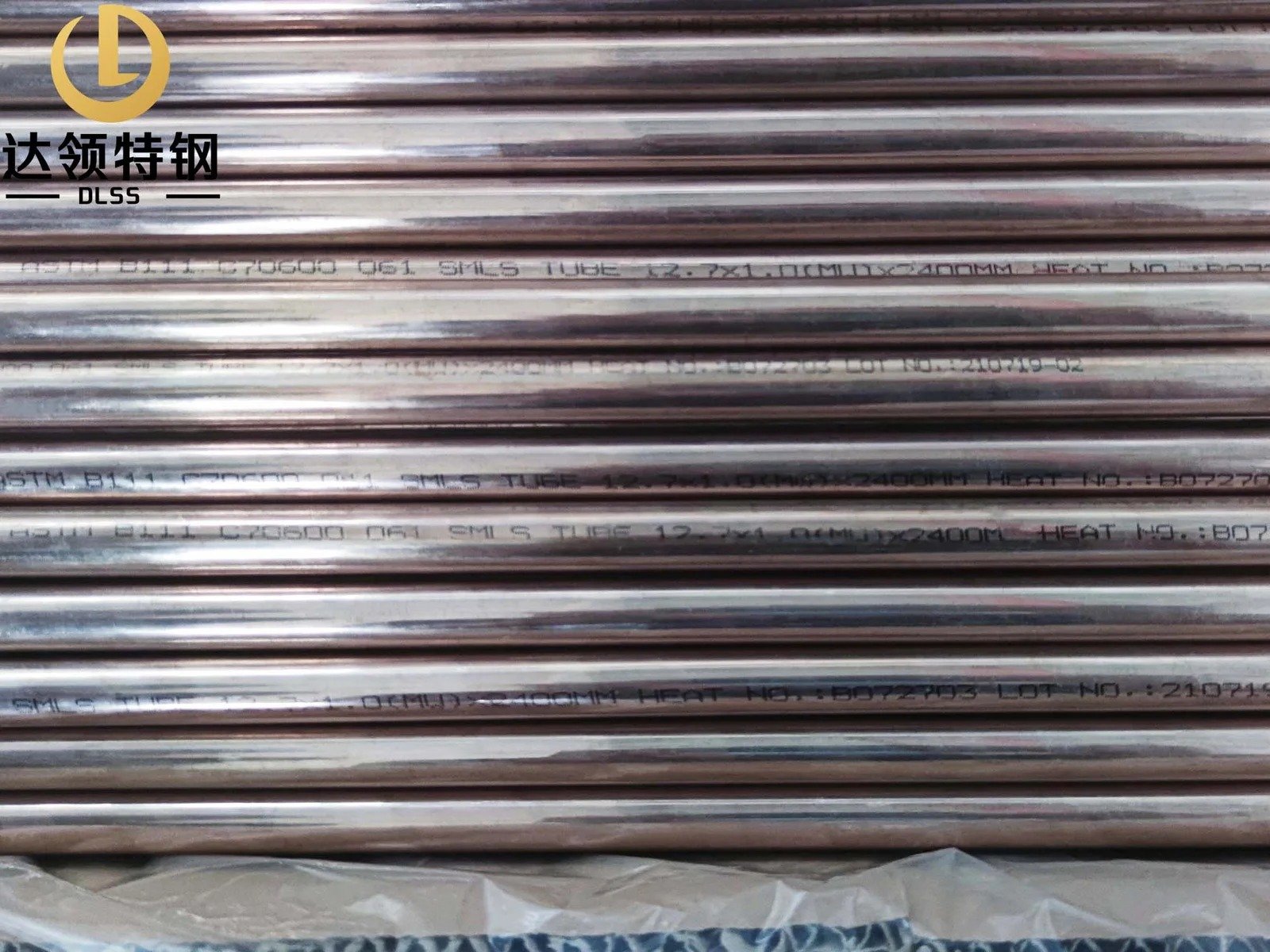

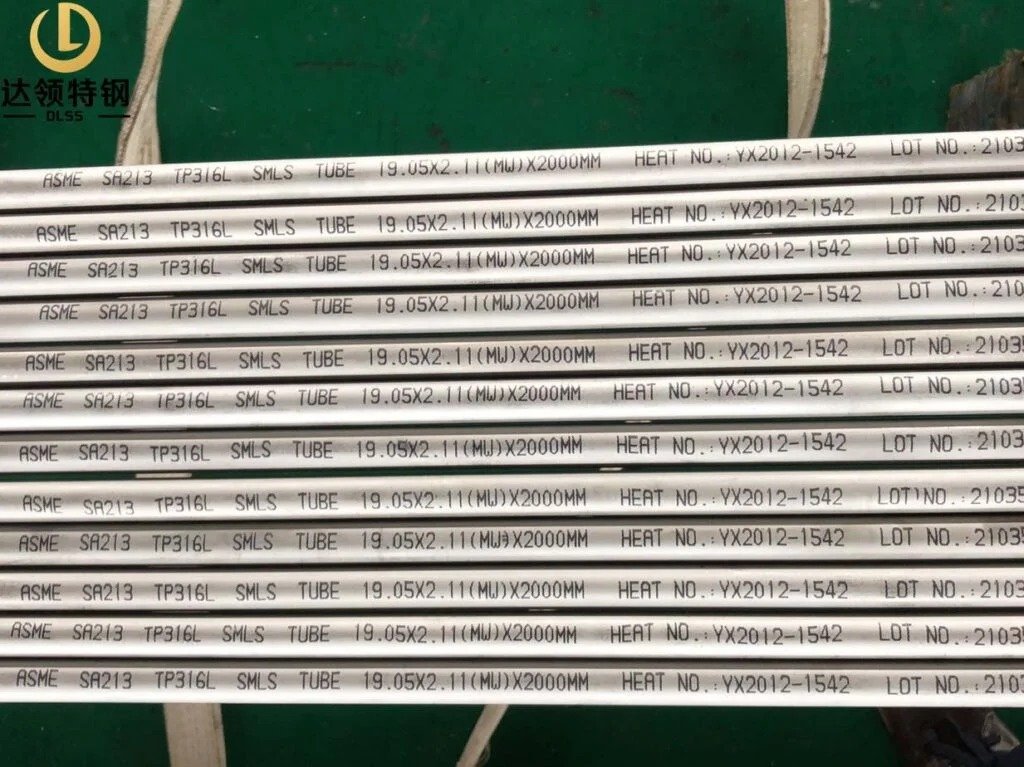

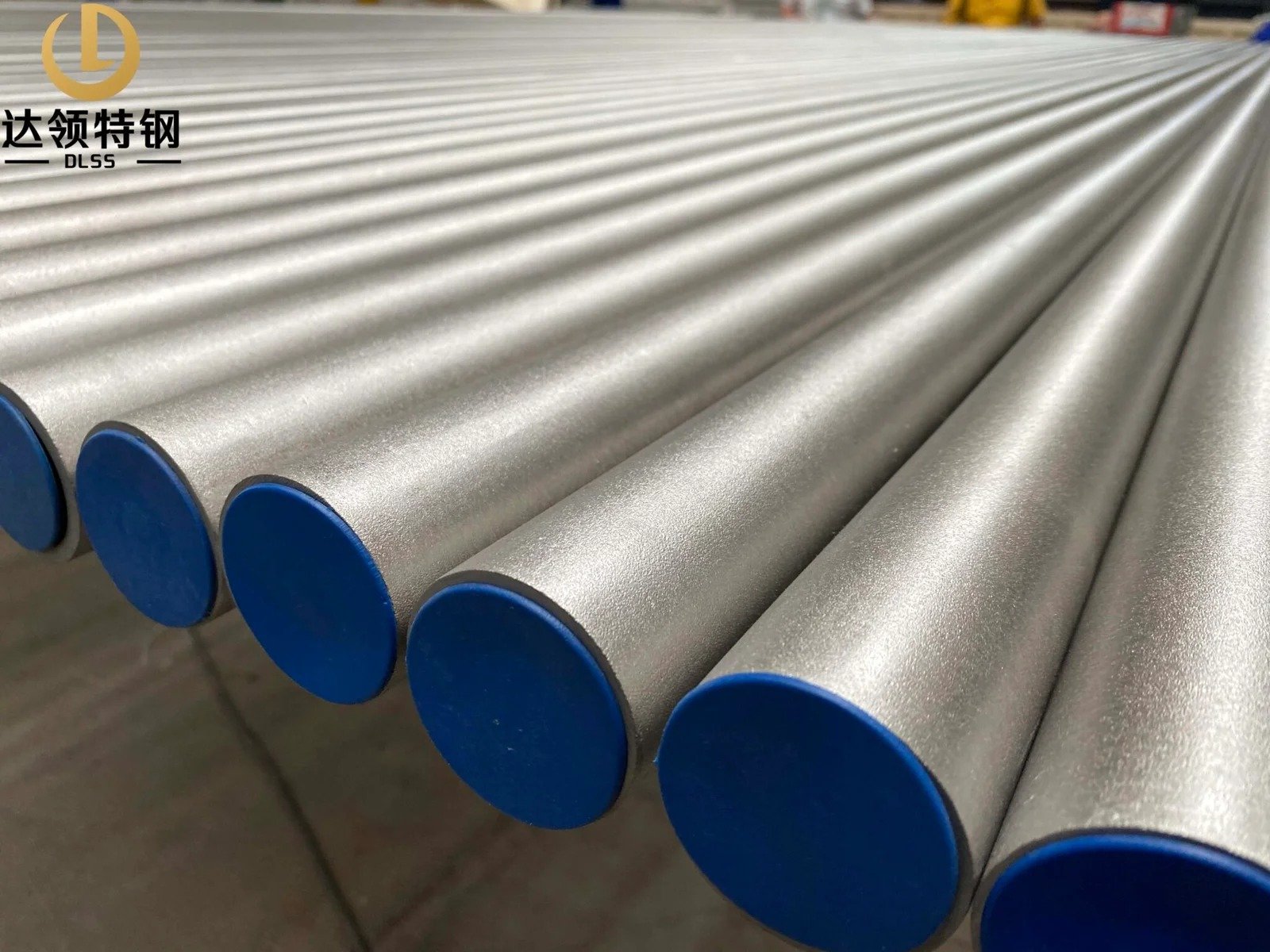

ASME SB111 C68700 Aluminium Brass Seamless Tube is widely used in cooling and heating systems, thanks to its excellent resistance to seawater corrosion, impingement attack, and biofouling. DLSS supplies C68700 (O61) seamless tubes in size 15.88 mm OD × 2.11 mm WT × 1840 mm length, manufactured strictly according to ASME SB111 standards and delivered in O61 annealed condition for superior ductility and workability.

What is C68700 Aluminium Brass Tube?

C68700 Aluminium Brass, also known as Admiralty Aluminium Brass, is a copper-zinc-aluminium alloy with:

-

~76% Copper

-

~22% Zinc

-

~2% Aluminium + trace Arsenic

This composition provides:

-

High seawater corrosion resistance (better than standard brass)

-

Resistance to biofouling in marine and cooling systems

-

Excellent mechanical strength with ductility under O61 condition

Specifications

| Item | Details |

|---|---|

| Standard | ASME SB111 |

| Material | C68700 Aluminium Brass (Cu-Zn-Al Alloy) |

| Condition | O61 (Annealed) |

| Type | Seamless Tube |

| Size | 15.88 mm OD × 2.11 mm WT × 1840 mm Length |

| Applications | Cooling & heating systems, power plants, condensers, marine equipment |

Key Features

-

Superior Seawater Resistance – performs reliably in saline and brackish water.

-

Anti-Biofouling Properties – aluminium content minimizes marine organism deposits.

-

Excellent Thermal Conductivity – efficient heat transfer for condensers and coolers.

-

O61 Annealed Condition – provides ductility and ease of bending into U-tubes or coils.

-

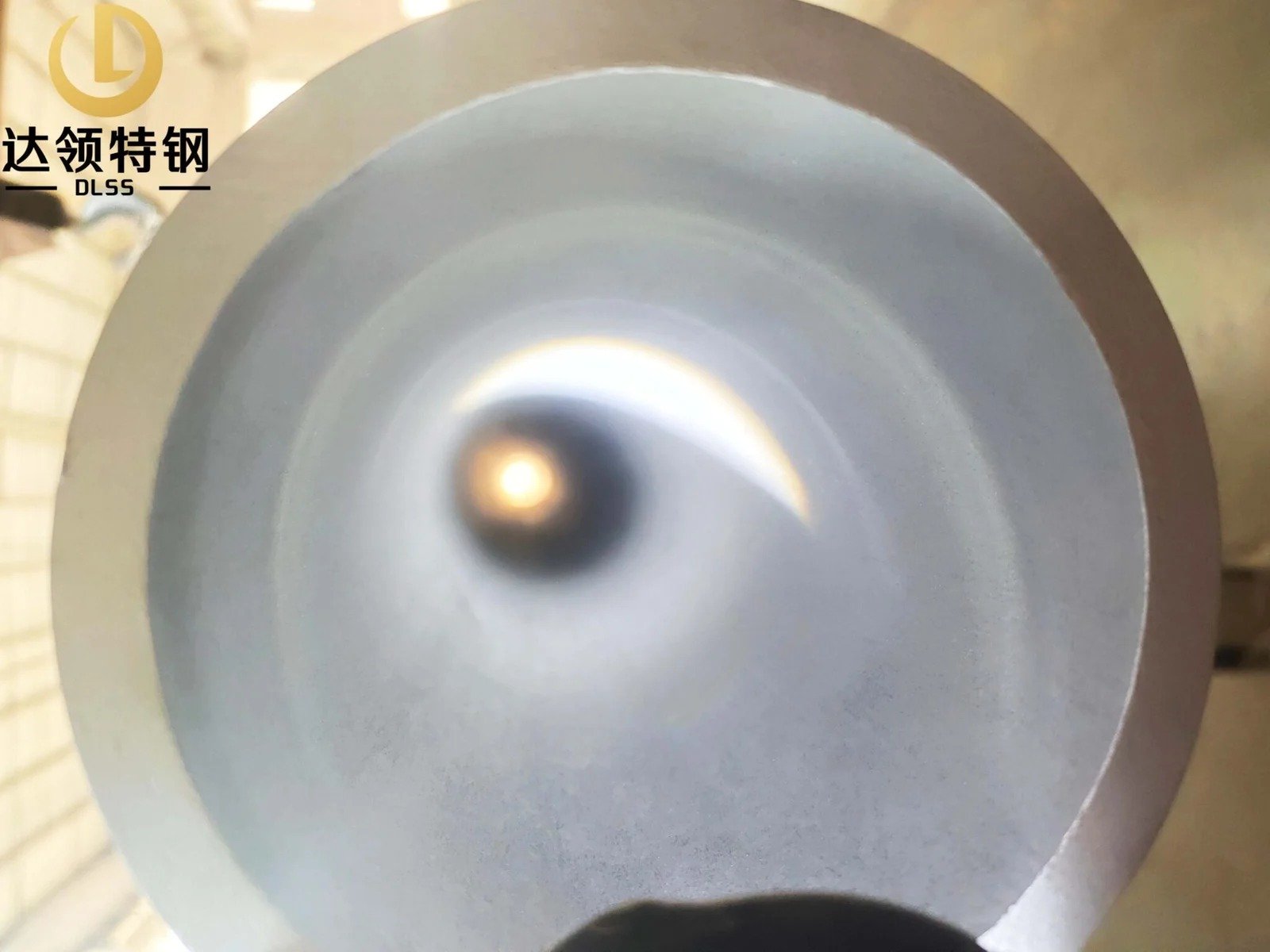

Seamless Tube Design – ensures high strength and leak-proof performance.

Applications

-

Cooling Water Systems – desalination, power plants, HVAC.

-

Heating Systems – industrial heat exchangers and condensers.

-

Marine Engineering – shipboard condensers and engine cooling lines.

-

Desalination Plants – highly resistant to saline and polluted waters.

-

Petrochemical Plants – durable tubes for heat transfer equipment.

Why Choose DLSS?

-

Full supply range of copper alloys: C44300, C68700, C70600, C71500.

-

Certified Quality – MTC EN 10204/3.1, with SGS/BV/TUV inspections.

-

Strict Testing – Eddy Current, Hydrostatic, and dimensional checks.

-

Seaworthy Export Packaging – capped ends, plastic wrap, ISPM-15 wooden cases.

-

Global Project Experience – trusted by shipyards, power plants, and industrial EPCs.

Frequently Asked Questions (FAQ)

Q1: Why is C68700 Aluminium Brass preferred over C44300 Admiralty Brass?

A1: Because the aluminium addition improves corrosion resistance and biofouling protection in seawater systems.

Q2: What does O61 mean?

A2: O61 indicates the annealed condition, providing ductility for bending and forming.

Q3: Can DLSS supply longer lengths?

A3: Yes, custom sizes and U-bent tubes are available.

Q4: What industries use C68700 tubes?

A4: Mainly power plants, desalination, marine, HVAC, and petrochemical projects.