Introduction

ASTM B111 C44300 Admiralty Brass Seamless Tube is widely used in boilers, condensers, and heat exchangers due to its excellent corrosion resistance, dezincification resistance, and thermal conductivity. DLSS supplies C44300 (O61) seamless tubes in size 20 mm OD × 2.0 mm WT × 6000 mm length, manufactured as cold finished boiler tubes to meet strict dimensional accuracy and mechanical property requirements.

The O61 annealed condition ensures ductility and ease of fabrication, making these tubes ideal for bending into U-tubes or assembling in tube bundles.

What is C44300 Admiralty Brass Tube?

C44300 Admiralty Brass is a copper-zinc-tin alloy containing:

-

~70% Copper

-

~29% Zinc

-

~1% Tin

This unique composition provides:

-

Superior resistance to seawater and brackish water corrosion

-

Dezincification resistance, even in polluted waters

-

High thermal conductivity, making it efficient for heat transfer

As a result, ASTM B111 C44300 seamless tubes are widely adopted in boiler, power plant, and marine cooling systems.

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B111 |

| Material | C44300 Admiralty Brass |

| Condition | O61 (Annealed) |

| Type | Seamless Tube, Cold Finished Boiler Tube |

| Size | 20 mm OD × 2.0 mm WT × 6000 mm Length |

| Corrosion Resistance | Excellent in fresh, brackish, and seawater |

| Applications | Boilers, condensers, heat exchangers, marine cooling, desalination |

Key Features

-

Cold Finished Boiler Tube – improved dimensional accuracy and surface finish.

-

Excellent Seawater Resistance – proven in brackish and polluted water conditions.

-

Dezincification Resistance – ensures long service life in aggressive media.

-

High Thermal Conductivity – efficient heat transfer in boilers and exchangers.

-

O61 Annealed Condition – provides ductility for fabrication and bending.

Applications

-

Boilers – cold finished tubes for heat transfer and steam generation.

-

Power Plant Condensers – seawater-cooled tube bundles.

-

Desalination Equipment – resistant to saline and brine conditions.

-

Marine Cooling Systems – reliable condenser and cooler tubes in ships.

-

Industrial Heat Exchangers – petrochemical and refinery processes.

Why Choose DLSS?

-

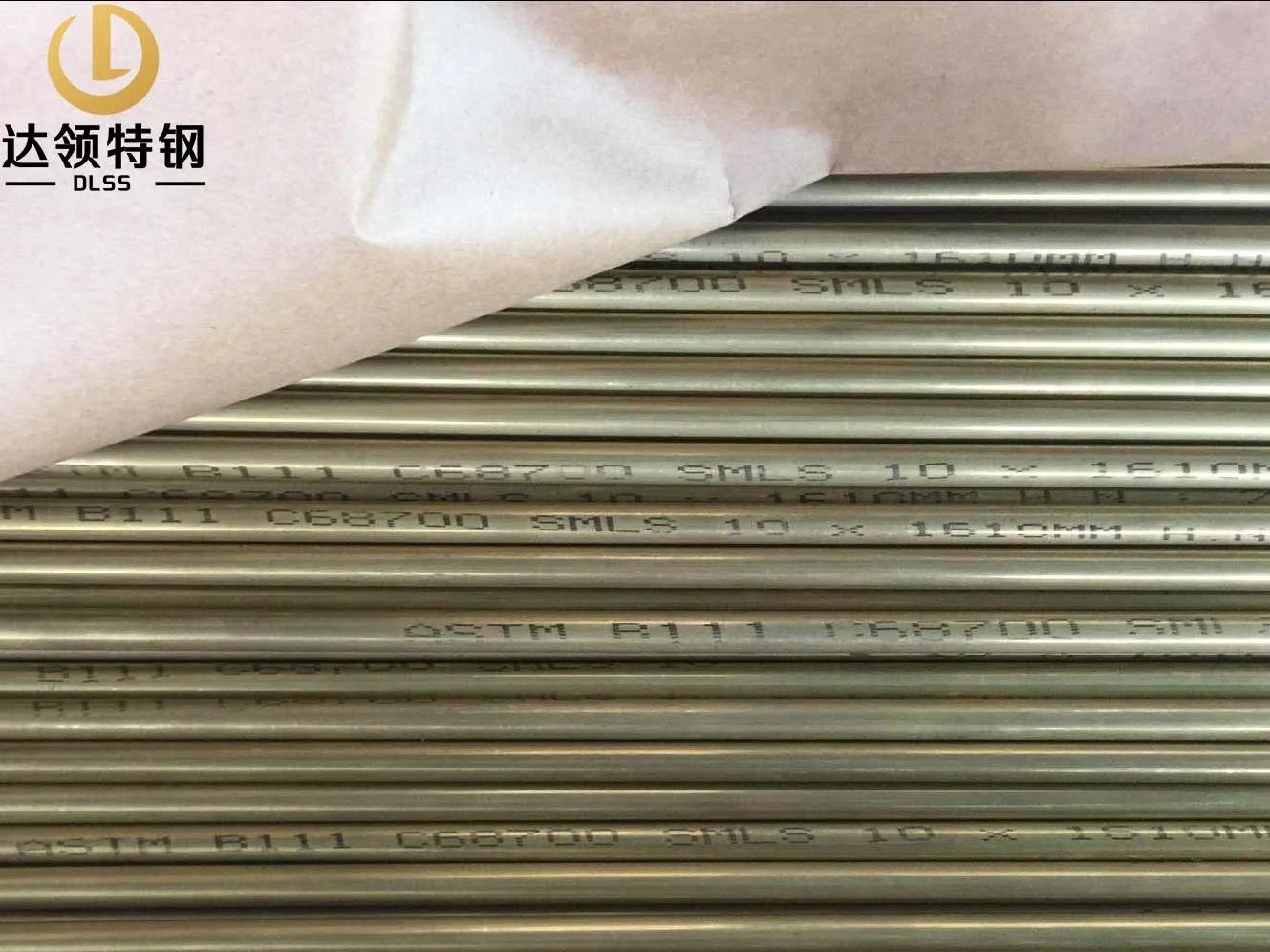

Complete supply of brass and copper alloy tubes: C44300, C68700, C70600, C71500.

-

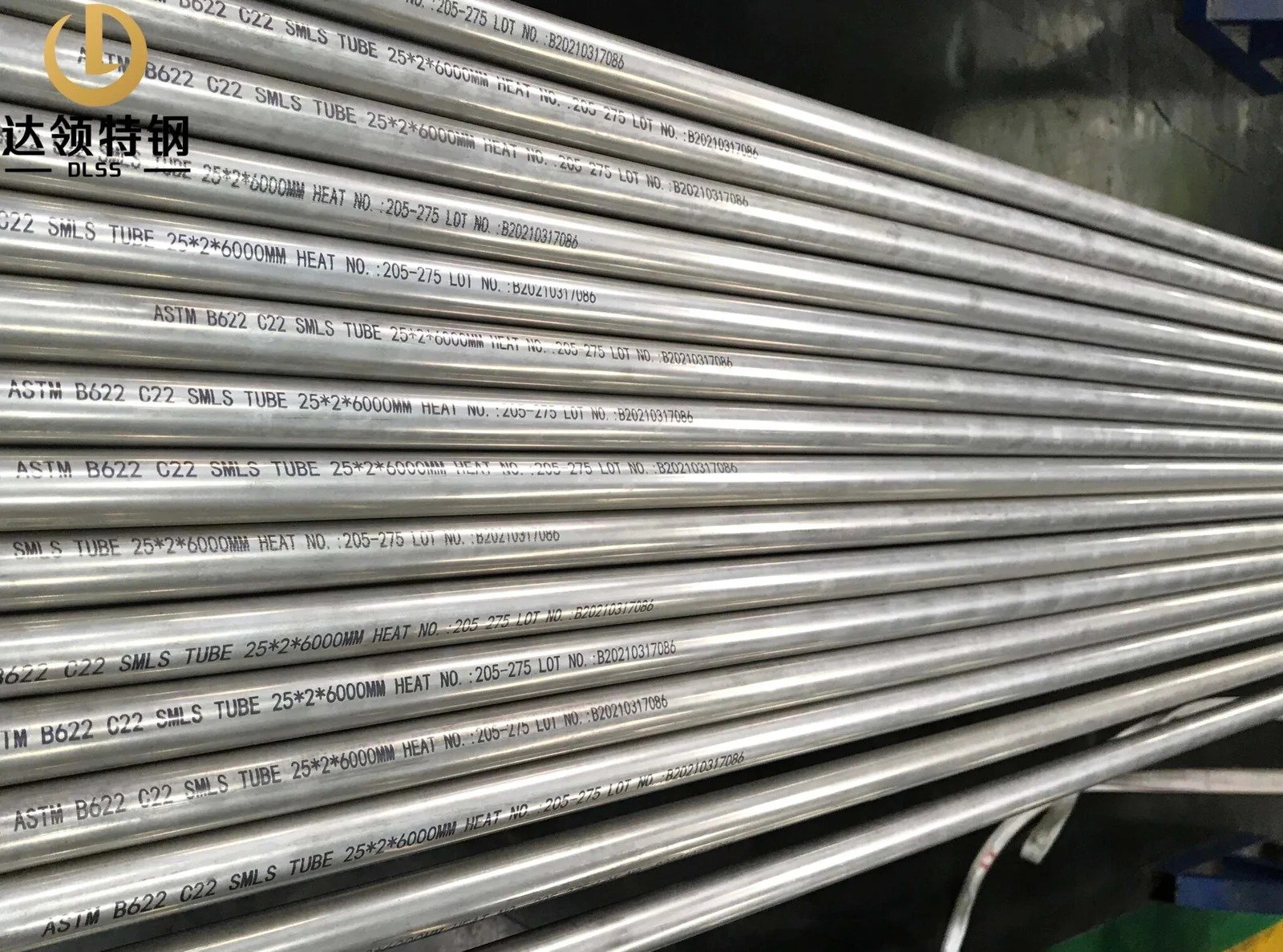

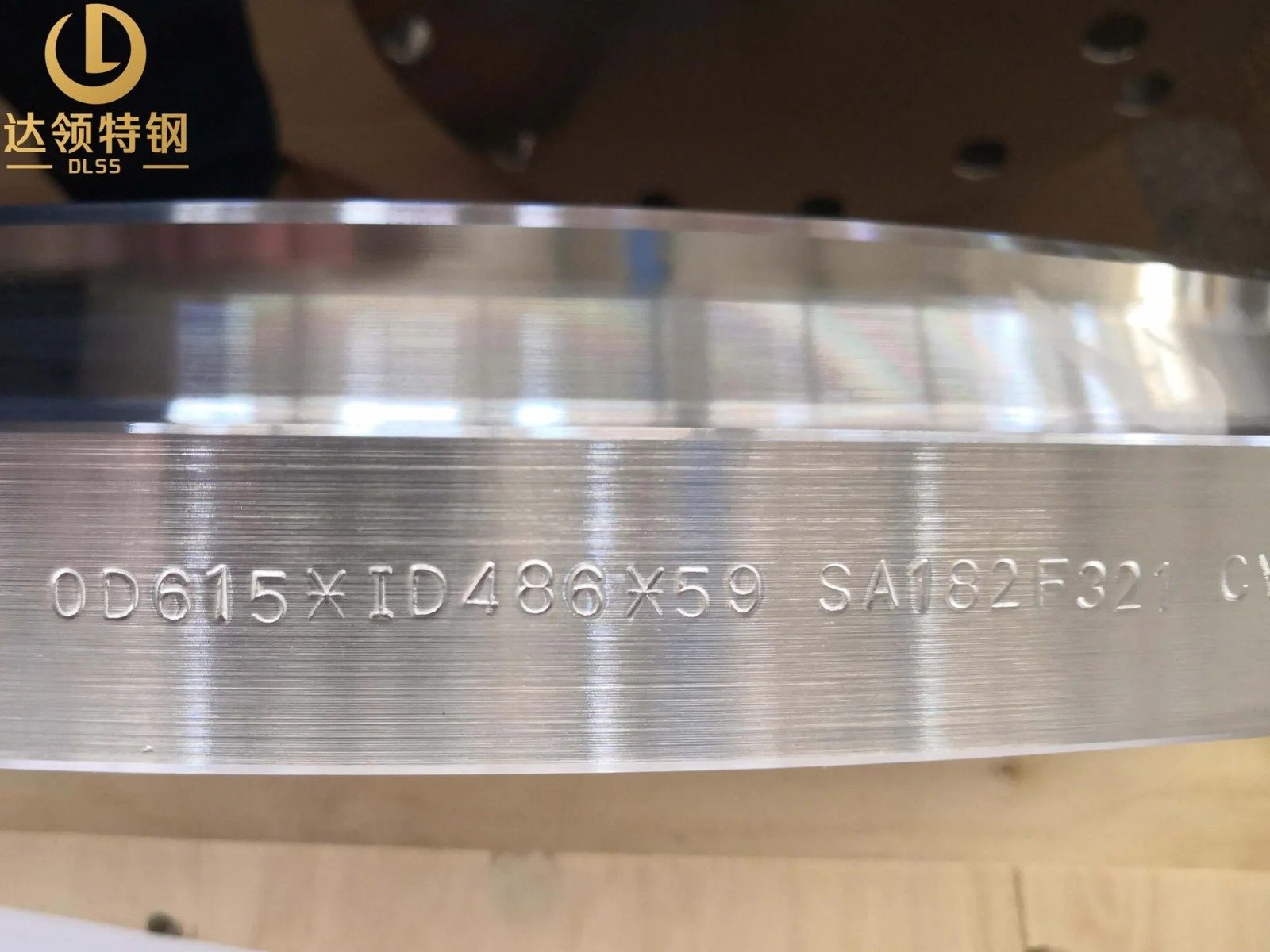

Certified quality – MTC EN 10204/3.1, third-party inspections (SGS, BV, TUV).

-

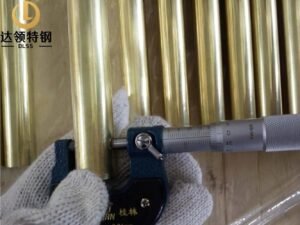

Cold finished precision – ensuring tight dimensional tolerances.

-

Export packaging – capped ends, plastic wrapping, ISPM-15 wooden cases.

-

Proven track record – global supply for boiler and condenser projects.

Frequently Asked Questions (FAQ)

Q1: Why is C44300 Admiralty Brass used for boiler tubes?

A1: Because it combines corrosion resistance, dezincification resistance, and heat transfer efficiency.

Q2: What does “cold finished” mean for boiler tubes?

A2: It refers to a finishing process that enhances dimensional accuracy, surface quality, and mechanical properties.

Q3: Can DLSS supply U-bend boiler tubes?

A3: Yes, U-tubes and cut-to-length tubes are available.

Q4: What third-party inspections are available?

A4: SGS, BV, and TUV inspections upon client request.