Introduction

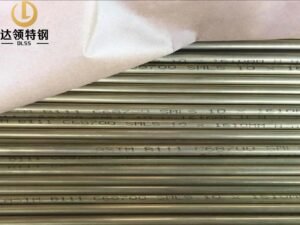

ASTM B111 C68700 Aluminium Brass Seamless Tube is widely recognized as a reliable material for condenser and cooling applications in power plants, desalination plants, and marine systems. DLSS supplies C68700 (O61) seamless tubes in size 10 mm OD × 1.0 mm WT × 1610 mm length, manufactured to ASTM B111 standards and delivered in O61 annealed condition for excellent ductility and fabrication performance.

What is ASTM B111 C68700 Aluminium Brass Tube?

C68700 Aluminium Brass, also known as Arsenical Aluminium Brass, is a copper-zinc alloy with aluminium and a small amount of arsenic. This composition enhances:

-

Resistance to seawater corrosion

-

Protection against biofouling and impingement attack

-

Durability in high-velocity and polluted water conditions

As a result, ASTM B111 C68700 seamless tubes are highly suitable for condenser and cooling tube bundles.

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B111 |

| Material | C68700 Aluminium Brass |

| Condition | O61 (Annealed) |

| Type | Seamless Tube |

| Size | 10 mm OD × 1.0 mm WT × 1610 mm Length |

| Applications | Condensers, cooling systems, power plants, desalination, marine piping |

Key Features

-

Excellent Seawater Resistance – reliable performance in saline and brackish waters.

-

Anti-Biofouling Properties – aluminium prevents marine organism deposits.

-

High Thermal Conductivity – efficient heat transfer in condensers and cooling systems.

-

O61 Annealed Condition – ductile and easy to bend or fabricate.

-

Proven Durability – long service life in marine and industrial environments.

Applications

-

Power Plant Condensers – seawater-cooled tube bundles.

-

Desalination Plants – brine-resistant condenser tubing.

-

Marine Engineering – shipboard cooling and condensers.

-

Industrial Cooling – petrochemical and refinery heat exchangers.

-

HVAC Systems – reliable thermal transfer in chilled water applications.

Why Choose DLSS?

-

Full supply of copper alloy tubes: C44300, C68700, C70600, C71500.

-

Certified quality – MTC EN 10204/3.1, optional SGS/BV/TUV inspection.

-

Strict QC & Testing – Eddy Current, Hydrostatic, and dimensional inspection.

-

Export packaging – capped ends, plastic wrapping, ISPM-15 wooden cases.

-

Global experience – supplied to power plants, shipyards, and industrial EPC projects.

Frequently Asked Questions (FAQ)

Q1: Why use C68700 Aluminium Brass tubes in condensers?

A1: Because they resist seawater corrosion, biofouling, and impingement, ensuring long service life.

Q2: What does O61 mean?

A2: O61 is the annealed condition, providing ductility for bending and fabrication.

Q3: Can DLSS supply longer condenser tubes?

A3: Yes, customized lengths and U-bend tubes are available.

Q4: What industries commonly use Aluminium Brass tubes?

A4: Power plants, desalination plants, marine cooling, petrochemical, and HVAC.