Introduction

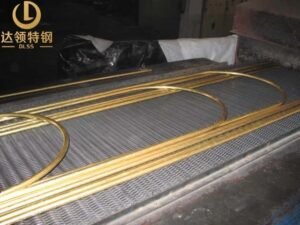

ASTM B111 / ASME SB111 Copper Alloy U-Bending Seamless Tubes are designed for heat exchanger and condenser applications, where reliable corrosion resistance, thermal conductivity, and bending performance are critical. These tubes are manufactured in seamless form, precision U-bent, and delivered in bright annealed condition to ensure smooth inner surfaces, enhanced cleanliness, and excellent heat transfer efficiency.

All tubes undergo 100% Eddy Current Testing (ET) to guarantee defect-free performance, making them suitable for demanding power plants, desalination, petrochemical, and marine heat exchanger projects.

Product Details

| Item | Details |

|---|---|

| Standard | ASTM B111 / ASME SB111 |

| Material | Copper Alloys (C44300 Admiralty Brass, C68700 Aluminium Brass, C70600 CuNi 90/10, C71500 CuNi 70/30, etc.) |

| Type | Seamless Tube, U-Bent |

| Heat Treatment | Bright Annealed |

| Testing | 100% Eddy Current Testing (ET) |

| Shape | Straight or U-Bending |

| Applications | Heat exchangers, condensers, power plants, desalination, marine systems |

Key Features

-

Seamless Construction – ensures mechanical strength and leak-free performance.

-

U-Bending Process – precisely formed for tube bundles in heat exchangers.

-

Bright Annealed Finish – smooth internal surface, reduced fouling, improved heat transfer.

-

100% Eddy Current Tested – guarantees defect-free supply for critical projects.

-

Wide Material Range – available in Admiralty Brass (C44300), Aluminium Brass (C68700), CuNi 90/10 (C70600), CuNi 70/30 (C71500).

Applications

-

Heat Exchangers & Condensers – in power generation, refineries, and chemical plants.

-

Desalination Units – seawater cooling and brine service.

-

Marine Engineering – shipboard cooling systems.

-

Industrial Cooling & Heating – HVAC and petrochemical facilities.

Why Choose DLSS?

-

Expertise in U-bend seamless tube manufacturing with tight bending radius control.

-

Complete copper alloy supply – from brass to copper-nickel grades.

-

International certifications – MTC EN 10204/3.1, SGS, BV, TUV optional.

-

Strict Quality Assurance – 100% ET, hydrostatic, and dimensional inspection.

-

Export Packaging – tube bundles protected with plastic caps, wrapping, and ISPM-15 wooden cases.

Frequently Asked Questions (FAQ)

Q1: Which copper alloys are available for ASTM B111 / ASME SB111 U-bending tubes?

A1: C44300 (Admiralty Brass), C68700 (Aluminium Brass), C70600 (CuNi 90/10), and C71500 (CuNi 70/30).

Q2: What is the benefit of bright annealed U-tubes?

A2: They have smoother surfaces, improved cleanliness, and enhanced heat transfer efficiency.

Q3: What inspections are included?

A3: 100% Eddy Current Testing (ET), hydrostatic testing, and third-party inspections (SGS, BV, TUV) if required.

Q4: Can DLSS supply tube bundles with U-bends ready for assembly?

A4: Yes, we provide pre-bent tube bundles for heat exchangers and condensers.