Introduction

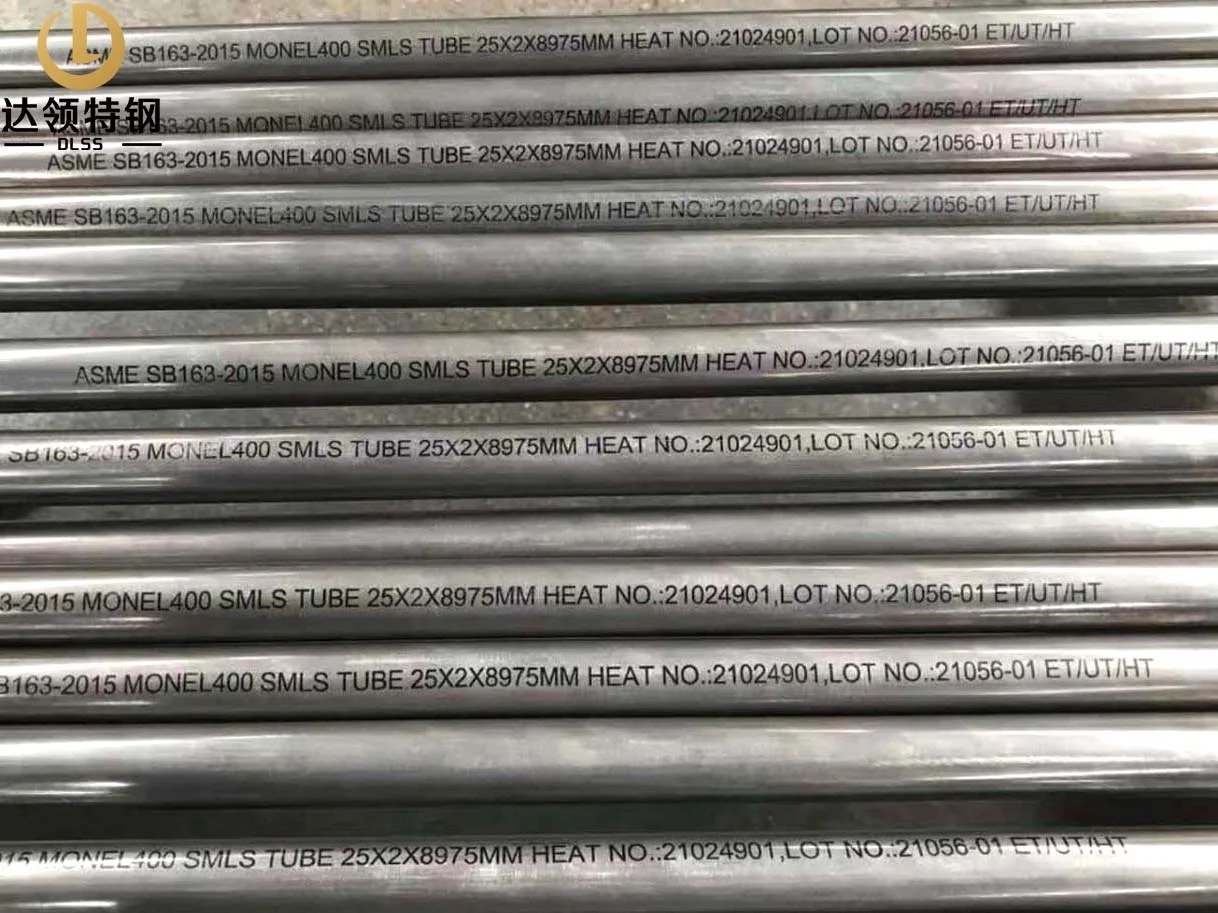

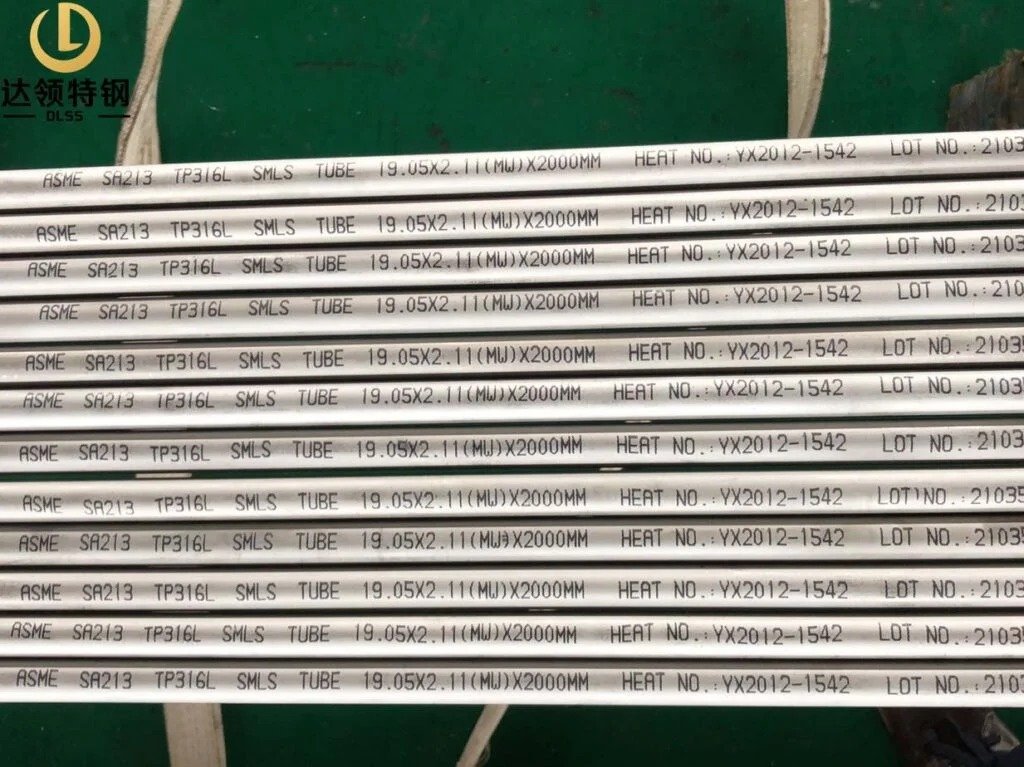

ASTM B444 Inconel 625 Seamless Tube is one of the most widely used nickel-based alloy tubes for heat exchangers, condensers, and offshore cooling systems. DLSS supplies seamless tubes in size 25.4 mm OD × 2.11 mm WT, manufactured to ASTM B444 Grade 2 standards, and precisely U-bent for exchanger bundles.

This batch of ASTM B444 Inconel 625 Seamless Tubes was supplied with a pickled surface finish, ensuring oxide-free, clean internal and external surfaces for superior corrosion resistance. Every tube underwent 100% hydrostatic testing (HT), eddy current testing (ET), and ultrasonic testing (UT) before shipment to South Africa, meeting the most demanding project requirements.

What is ASTM B444 Inconel 625 Seamless Tube?

ASTM B444 Inconel 625 Seamless Tube (UNS N06625) is made of a nickel-chromium-molybdenum-niobium alloy with exceptional strength and corrosion resistance. Its composition includes:

-

Nickel ≥58%

-

Chromium 20–23%

-

Molybdenum 8–10%

-

Niobium + Tantalum 3–4%

This unique chemistry allows the ASTM B444 Inconel 625 Seamless Tube to resist pitting, crevice corrosion, stress corrosion cracking, and oxidation in aggressive chloride and high-temperature environments.

Specifications of ASTM B444 Inconel 625 Seamless Tube

| Item | Details |

|---|---|

| Standard | ASTM B444 Grade 2 |

| Material | Inconel 625 (UNS N06625) |

| Type | Seamless U-Bending Tube |

| Size | 25.4 mm OD × 2.11 mm WT |

| Surface Finish | Pickled Surface |

| Condition | Solution Annealed (Grade 2) |

| Testing | 100% HT / ET / UT |

| Export Destination | South Africa |

| Applications | Heat exchangers, condensers, petrochemical, marine, offshore, power plants |

Key Features of ASTM B444 Inconel 625 Seamless Tube

-

Seamless Construction – high strength and reliability for critical pressure service.

-

Pickled Surface Finish – removes oxides, improves cleanliness and corrosion resistance.

-

Exceptional Corrosion Resistance – resists seawater, chlorides, acids, and oxidizing media.

-

High-Temperature Strength – maintains mechanical integrity up to 1000°C.

-

100% Tested – hydrostatic, eddy current, and ultrasonic inspections ensure defect-free supply.

-

Global Supply Experience – recently delivered to South African industrial projects.

Applications of ASTM B444 Inconel 625 Seamless Tube

-

Heat Exchangers & Condensers – handling seawater, brine, and chemical solutions.

-

Offshore Oil & Gas – risers, subsea pipelines, and platform heat exchangers.

-

Desalination Plants – resistant to chloride stress corrosion cracking in brine environments.

-

Marine Cooling Systems – shipboard condensers and seawater piping.

-

Chemical Processing – sulfuric acid, phosphoric acid, and oxidizing chemical environments.

-

Power Plants – high-temperature boiler and condenser tubing.

Why Choose DLSS for ASTM B444 Inconel 625 Seamless Tube?

-

Wide range of nickel alloys: Inconel, Incoloy, Monel, Hastelloy.

-

Precision U-bending – accurate radius control for exchanger bundles.

-

Strict Quality Control – 100% HT, ET, UT + PMI + dimensional checks.

-

Third-Party Inspections – SGS, BV, TUV certifications available.

-

Seaworthy Packaging – capped, plastic-wrapped, ISPM-15 wooden cases.

-

Global Export – supplied to South Africa, Middle East, Europe, Asia-Pacific.

Frequently Asked Questions (FAQ)

Q1: Why use ASTM B444 Inconel 625 Seamless Tube in heat exchangers?

A1: It resists chloride corrosion, seawater, and high-temperature oxidation, ensuring long-term reliability.

Q2: What is the benefit of pickled surface tubes?

A2: Pickling removes mill scale and oxides, leaving a clean and corrosion-resistant surface.

Q3: What is Grade 2 in ASTM B444?

A3: Grade 2 refers to solution-annealed Inconel 625, which offers excellent ductility and weldability.

Q4: Can DLSS supply both straight and U-bend Inconel 625 tubes?

A4: Yes, complete tube packages (straight, U-bend, finned) are available.