Introduction

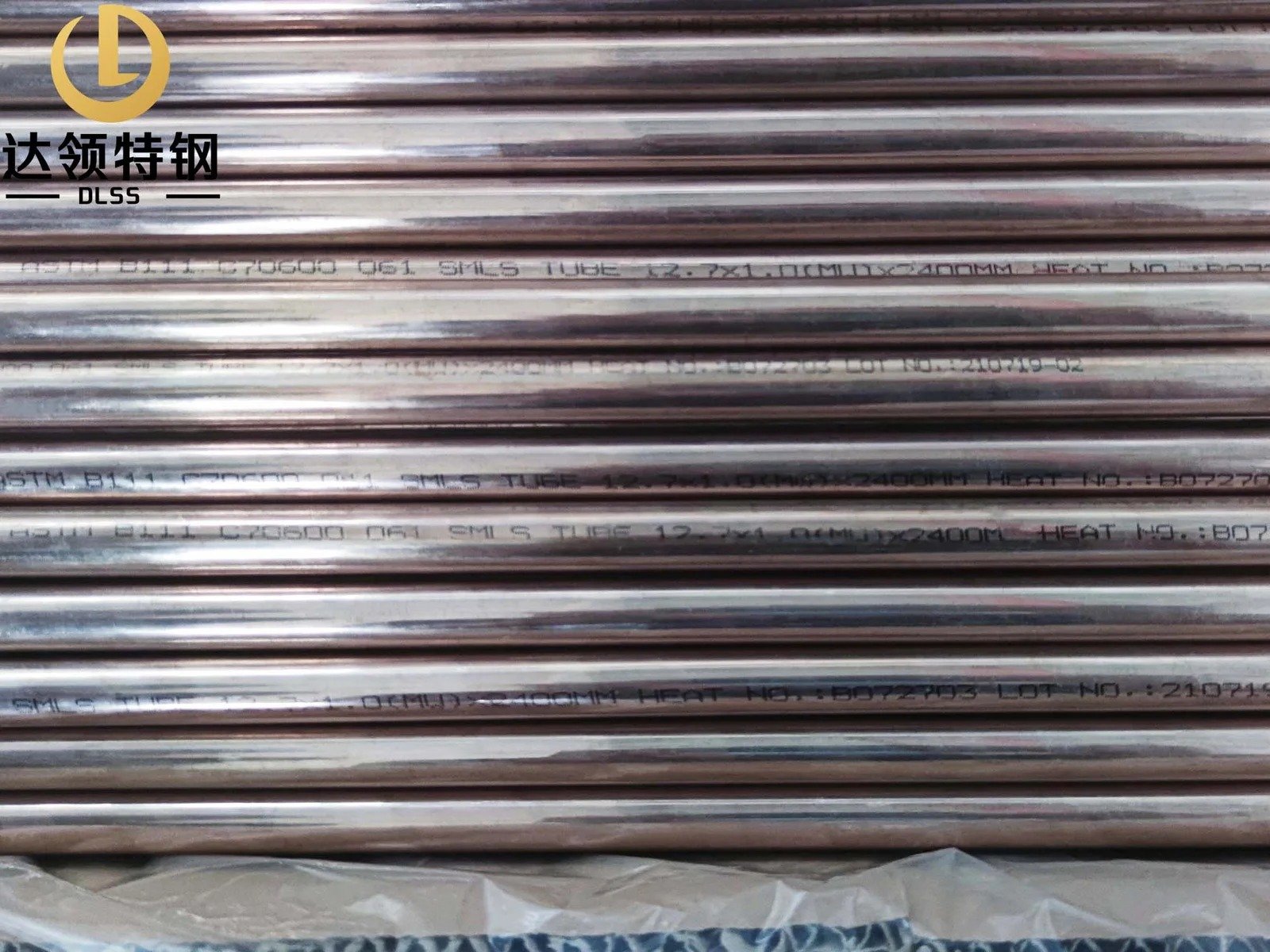

ASTM B622 Hastelloy C22 Seamless Tube (UNS N06022) is a nickel-chromium-molybdenum-tungsten alloy tube designed for extreme corrosion resistance in both oxidizing and reducing environments. DLSS supplies seamless tubes in size 25 mm OD × 2 mm WT × 6000 mm length, manufactured according to ASTM B622 and delivered with a bright annealed surface finish, ensuring smoothness, cleanliness, and enhanced corrosion resistance.

Hastelloy C22 seamless tubes are widely used in heat exchangers, chemical processing, pollution control, flue gas scrubbers, and marine applications, where superior resistance to pitting, crevice attack, and stress corrosion cracking is essential.

What is Hastelloy C22 (UNS N06022)?

Hastelloy C22 is an advanced nickel-based superalloy with the following composition:

-

Nickel (Ni) – balance

-

Chromium (Cr) – ~22%

-

Molybdenum (Mo) – ~13%

-

Tungsten (W) – ~3%

-

Iron (Fe) – 2–6%

Key benefits of ASTM B622 Hastelloy C22 Seamless Tube:

-

Exceptional resistance to oxidizing and reducing chemicals

-

Strong resistance to pitting and crevice corrosion

-

Protection against wet chlorine, hypochlorite, and oxidizing salts

-

Excellent performance in mixed acid environments (sulfuric, nitric, hydrochloric, phosphoric)

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B622 |

| Material | Hastelloy C22 (UNS N06022) |

| Type | Seamless Tube |

| Size | 25 mm OD × 2 mm WT × 6000 mm Length |

| Surface Finish | Bright Annealed |

| Condition | Solution Annealed |

| Applications | Heat exchangers, chemical processing, flue gas scrubbers, marine, pollution control |

Key Features of ASTM B622 Hastelloy C22 Seamless Tube

-

Bright Annealed Surface – clean, smooth, oxide-free surface for maximum corrosion resistance.

-

Superior Corrosion Resistance – performs in both oxidizing and reducing conditions.

-

Resistance to Chlorides – protects against pitting, crevice corrosion, and stress corrosion cracking.

-

High Temperature Capability – stable mechanical strength at elevated temperatures.

-

Versatile Alloy – suitable for aggressive chemical process environments.

Applications

-

Heat Exchangers & Condensers – handling aggressive chemicals and seawater.

-

Chemical Processing – reactors, scrubbers, evaporators, and piping systems.

-

Pollution Control Systems – flue gas scrubbers, waste treatment, and incineration.

-

Marine Engineering – seawater-cooled exchangers and piping.

-

Pharmaceutical & Food Industry – equipment exposed to mixed acids and sterilization.

Hastelloy C22 vs Hastelloy C276 – Comparison

| Item / Alloy | Hastelloy C22 (UNS N06022) | Hastelloy C276 (UNS N10276) |

|---|---|---|

| Standard | ASTM B622 / B619 / B626 | ASTM B622 / B619 / B626 |

| Key Composition | Ni (balance), Cr ~22%, Mo ~13%, W ~3%, Fe 2–6% | Ni (balance), Cr ~16%, Mo ~16%, W ~3.5%, Fe 4–7% |

| Corrosion Resistance | Superior in oxidizing environments such as wet chlorine, nitric acid mixtures, and oxidizing salts | Superior in reducing environments such as hydrochloric acid, sulfuric acid, and chloride solutions |

| Pitting / Crevice Corrosion | Excellent, especially in oxidizing chloride environments | Excellent, especially in strong chloride and acidic environments |

| Stress Corrosion Cracking | Outstanding resistance under chloride stress conditions | Outstanding, widely used in chemical and energy industries |

| High-Temperature Performance | Stable up to ~1250°C | Stable up to ~1250°C |

| Typical Applications | – Wet chlorine systems – Oxidizing acid mixtures – Flue gas desulfurization units – Chemical processing – Seawater cooling |

– Hydrochloric and sulfuric acid systems – Pharmaceutical and chemical processing – Seawater cooling – Waste treatment equipment – Flue gas scrubbers |

| Summary | Best choice for oxidizing corrosive environments | Best choice for reducing corrosive environments |

Professional Summary

-

Hastelloy C22 is more suitable for oxidizing chemical environments such as wet chlorine, nitric acid mixtures, and oxidizing salts.

-

Hastelloy C276 performs better in reducing environments like hydrochloric and sulfuric acid systems.

For projects involving oxidizing conditions (e.g., FGD systems, wet chlorine service), choose C22.

For projects exposed to reducing acids and chloride-rich conditions, choose C276.

Why Choose DLSS?

-

Complete supply of nickel alloys: Hastelloy C22, C276, Inconel, Incoloy, Monel.

-

Strict Testing – 100% Eddy Current, Hydrostatic, Ultrasonic, and PMI.

-

Third-Party Inspection – SGS, BV, TUV available.

-

Export Packaging – capped ends, plastic wrapping, ISPM-15 wooden cases.

-

Global Supply – trusted for projects in chemical, marine, and environmental industries.