Introduction

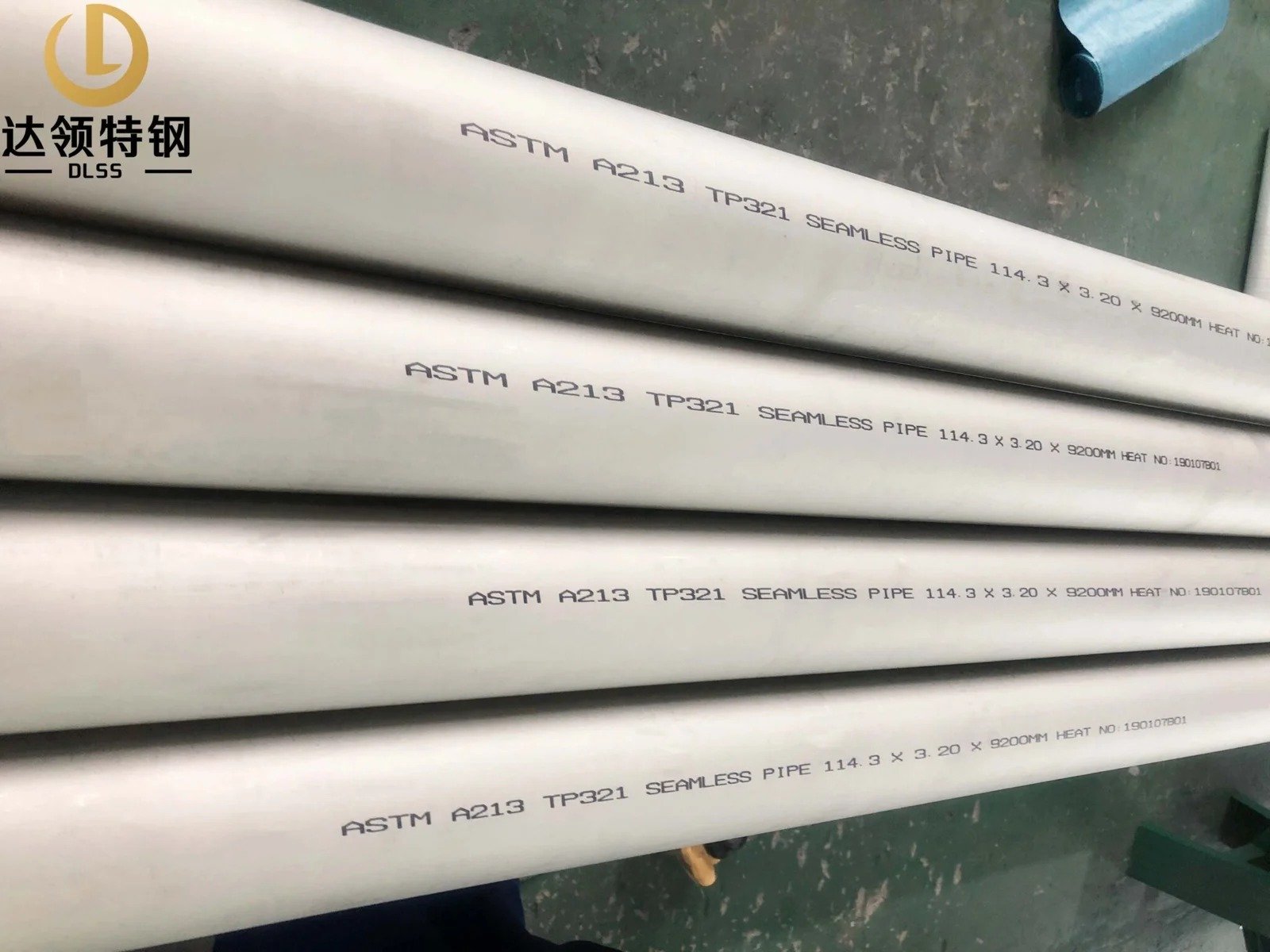

ASTM A403 WP316L Seamless 90° Elbow is a stainless steel pipe fitting designed to change the flow direction of pipelines by 90 degrees. Produced from low-carbon austenitic stainless steel 316L, this seamless elbow provides superior resistance to chlorides, acids, and seawater corrosion compared to standard 304 stainless steel.

DLSS supplies Short Radius (SR) 90° elbows, size 2″, thickness SCH80S, manufactured to ASTM A403 and ASME B16.9, ensuring strict dimensional tolerances and durability for high-pressure service. With its enhanced corrosion resistance, WP316L elbows are widely used in oil & gas, offshore, power generation, and chemical processing industries.

Key Features

-

Material: ASTM A403 WP316L (Low-carbon stainless steel)

-

Type: Seamless (SMLS) for maximum strength and smooth flow

-

Design: 90° Short Radius (SR) Elbow – compact for limited-space installations

-

Schedule: SCH80S, heavy wall thickness for pressure applications

-

Standard: ASME B16.9 – international dimension and tolerance compliance

-

Size: 2″ (DN50) Nominal Bore

Specifications

| Item | Details |

|---|---|

| Standard | ASTM A403 / ASME B16.9 |

| Material | Stainless Steel WP316L |

| Type | Seamless 90° Elbow (SMLS) |

| Size | 2″ (DN50) |

| Radius Type | Short Radius (SR) |

| Wall Thickness | SCH80S |

| Surface Finish | Pickled / Polished / Customized |

| Applications | Oil & Gas, Marine, Power Plants, Boilers, Heat Exchangers, Chemicals |

WP304 vs WP316L – Material Comparison

| Item / Grade | WP304 (ASTM A403) | WP316L (ASTM A403) |

|---|---|---|

| Chemical Composition | Cr 18–20%, Ni 8–10.5%, Fe balance | Cr 16–18%, Ni 10–14%, Mo 2–3%, Fe balance |

| Corrosion Resistance | Good in general atmospheric & mild chemicals | Superior – resists chlorides, seawater, acidic media |

| Molybdenum Content | None | 2–3% – enhances pitting & crevice corrosion resistance |

| Carbon Content | ≤0.08% | ≤0.03% – prevents carbide precipitation (welded service) |

| Stress Corrosion Cracking | Moderate performance | Excellent resistance in chloride-rich environments |

| Applications | General piping, water lines, low-corrosion service | Oil & Gas, Marine, Offshore, Chemical, Power Plants |

| Cost Level | Lower | Slightly higher, but longer service life in harsh conditions |

| Summary | Economical choice for mild environments | Best choice for aggressive chemical & marine service |

Professional Summary

-

WP304 is suitable for general piping applications where corrosion exposure is moderate.

-

WP316L is recommended for offshore, marine, and aggressive chemical service, thanks to its molybdenum addition and low-carbon content.

If your system is chloride-rich (e.g., seawater, brine, acids) → choose WP316L.

If your system is general-purpose, less corrosive → WP304 may be sufficient.

Applications of WP316L Seamless Elbow

-

Oil & Gas Industry – pipelines, offshore risers, and subsea service.

-

Marine Engineering – shipbuilding, desalination, seawater cooling systems.

-

Chemical Processing – reactors, acid piping, scrubbers.

-

Power Generation – boilers, heat exchangers, and high-pressure piping.

-

Pharma & Food Industry – hygienic piping with high corrosion resistance.

Why Choose DLSS?

-

Comprehensive range of stainless steel fittings: elbows, tees, reducers, stub ends.

-

Strict Quality Assurance – PMI, Hydro, UT, ET, dimensional inspection.

-

Third-Party Inspection – SGS, BV, TUV approved.

-

Export Packaging – capped ends, plastic bags, ISPM-15 wooden cases.

-

Global References – supplied stainless steel elbows and fittings to oil refineries, power stations, and marine projects in 40+ countries.