Introduction

ASTM A815 WPS32205 Seamless 180° Bend is a duplex stainless steel pipe fitting designed for applications requiring a full 180° flow redirection while maintaining strength and corrosion resistance. Manufactured from UNS S32205 duplex stainless steel, this seamless bend provides excellent performance in chloride-rich environments such as seawater and chemical processing.

DLSS supplies DN50, SCH10S, centerline dimension (CD) = 143 mm bends, produced to ASTM A815 and compliant with ASME B16.9, ensuring dimensional accuracy and long service life.

Key Features

-

Material: Duplex Stainless Steel WPS32205 (UNS S32205)

-

Type: Seamless 180° Bend (SMLS)

-

Size: DN50 (2″ Nominal Bore)

-

Schedule: SCH10S (thin wall, good for low/medium pressure service)

-

Centerline Dimension (CD): 143 mm

-

Standard: ASTM A815 / ASME B16.9

-

Corrosion Resistance: Excellent against chlorides, seawater, and aggressive chemicals

-

Strength: About 2× yield strength of standard 304/316 stainless steel

Specifications

| Item | Details |

|---|---|

| Standard | ASTM A815 / ASME B16.9 |

| Material | Duplex Stainless Steel S32205 |

| Type | Seamless 180° Bend (SMLS) |

| Size | DN50 (2″) |

| Schedule | SCH10S |

| Centerline Dimension | 143 mm |

| Radius Type | 180° return bend |

| Surface Finish | Pickled / Polished / Customized |

| Applications | Offshore, Marine, Oil & Gas, Heat Exchangers, Chemical Plants |

Applications

-

Offshore & Marine Engineering – seawater cooling loops, shipbuilding.

-

Oil & Gas Industry – pipelines exposed to chlorides and high pressure.

-

Heat Exchangers – return bends in tube bundles and piping systems.

-

Chemical Processing – piping for acids, brine, and aggressive media.

-

Water Treatment & Desalination – intake and discharge piping.

Advantages of Duplex S32205

-

High Strength – yield strength nearly double that of 316L stainless steel.

-

Corrosion Resistance – strong resistance to pitting, crevice corrosion, and SCC.

-

Extended Durability – longer service life in chloride-rich environments.

-

Cost Efficiency – reliable alternative to expensive nickel alloys.

Why Choose DLSS?

-

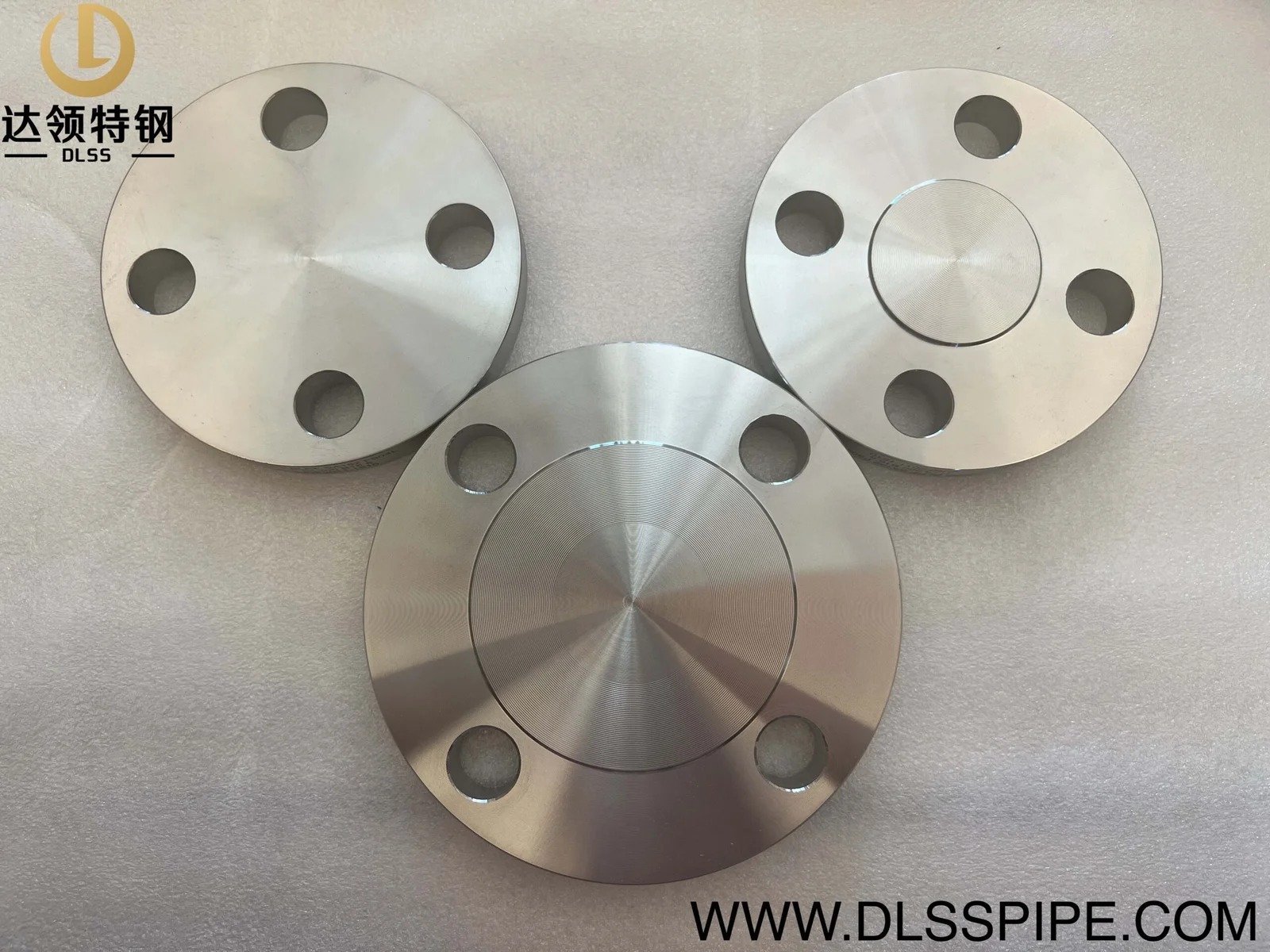

Full range of duplex and super duplex fittings: bends, elbows, tees, reducers, flanges.

-

Strict Quality Control – PMI, Hydro, UT, ET, dimensional testing.

-

Third-Party Certification – SGS, BV, TUV available.

-

Export-Ready Packaging – capped ends, plastic wrapping, ISPM-15 wooden cases.

-

Global Experience – supplied duplex fittings to offshore, petrochemical, and power projects worldwide.