Introduction

The ASTM A790 S32205 Seamless Pipe is a duplex stainless steel product engineered for industries that demand both mechanical strength and exceptional corrosion resistance. Duplex S32205 contains a balanced microstructure of austenite and ferrite, giving it nearly twice the yield strength of 316L stainless steel while maintaining excellent toughness and weldability.

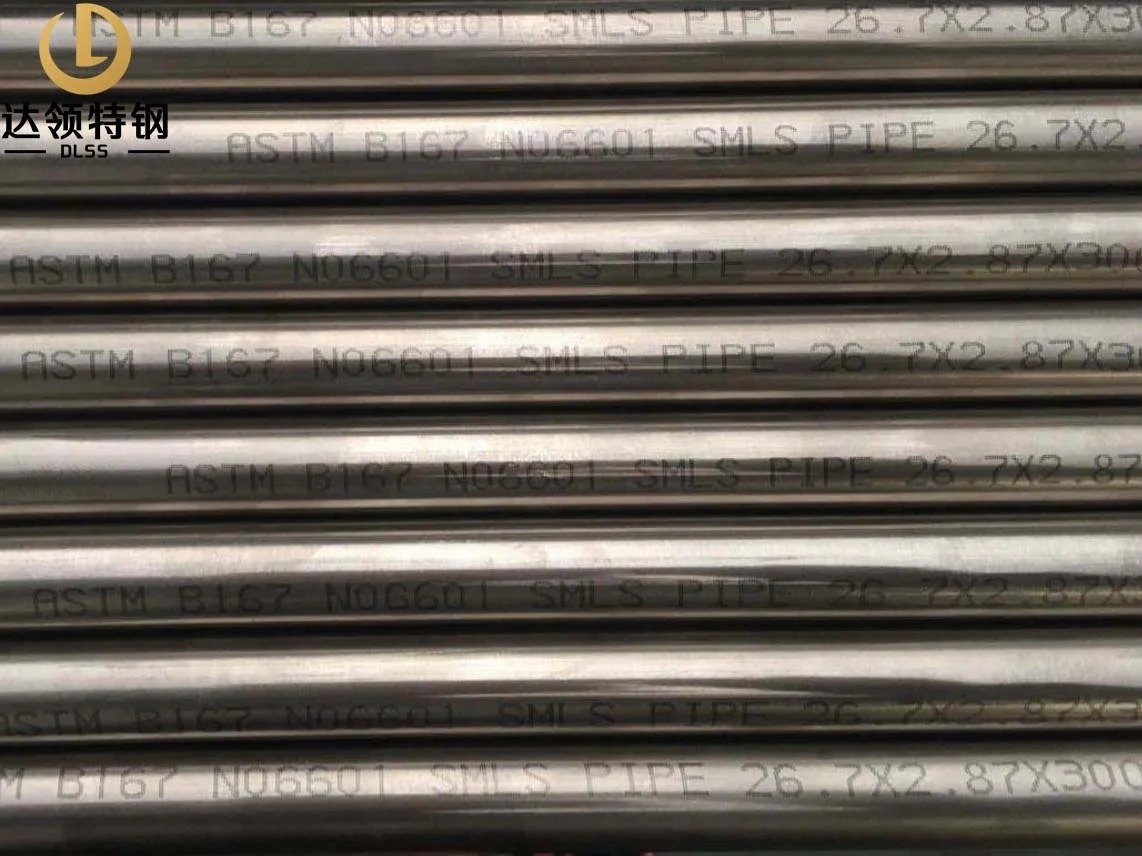

DLSS supplies DN50 SCH10S seamless pipes with a length of 1030 mm, manufactured to ASTM A790 specifications. Each pipe undergoes pickling, annealing, and 100% heat treatment, ensuring reliable performance in marine, offshore, oil & gas, chemical, and power generation applications.

Key Features

-

Material: Duplex Stainless Steel UNS S32205

-

Standard: ASTM A790

-

Type: Seamless Pipe (SMLS)

-

Size: DN50 (2″ Nominal Bore)

-

Wall Thickness: SCH10S (thin wall, suitable for moderate pressure systems)

-

Length: 1030 mm

-

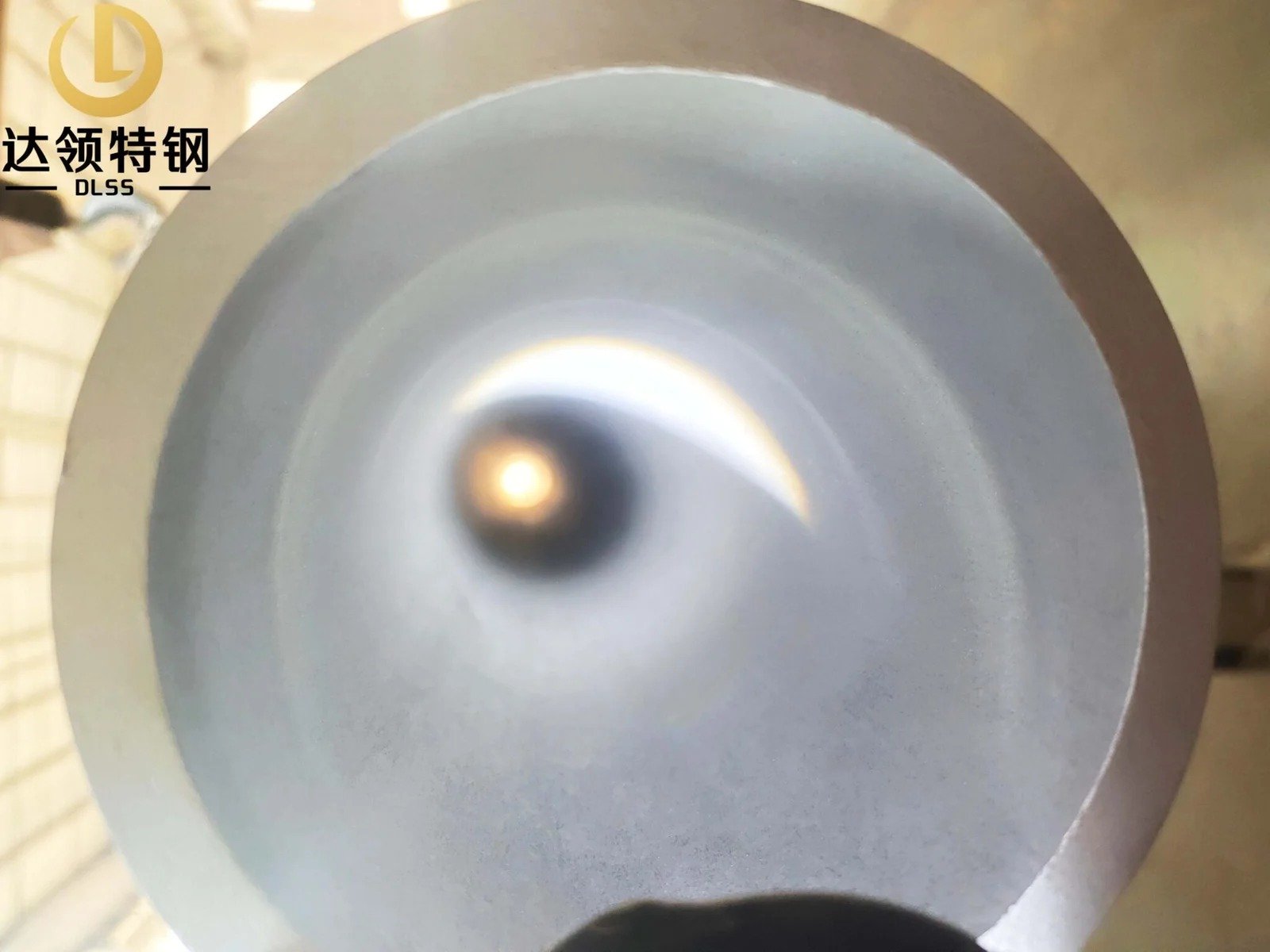

Surface Finish: Pickled & Annealed for smooth and corrosion-protected surface

-

Heat Treatment: 100% HT for structural integrity and corrosion resistance

-

Strength: Yield strength ≈ 450 MPa, almost double that of 304/316L

Specifications

| Item | Details |

|---|---|

| Standard | ASTM A790 |

| Material | Duplex Stainless Steel S32205 |

| Type | Seamless Pipe |

| Size | DN50 (2″) |

| Schedule | SCH10S |

| Length | 1030 mm |

| Surface Finish | Pickled & Annealed |

| Heat Treatment | 100% HT |

| Applications | Marine, Offshore, Oil & Gas, Power, Chemical, Desalination |

Why Choose Duplex S32205?

-

High Mechanical Strength

– Provides nearly double the yield strength compared to standard austenitic stainless steels. -

Superior Corrosion Resistance

– Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking, especially in seawater and chloride-rich environments. -

Balanced Microstructure

– 50% ferrite and 50% austenite structure provides both toughness and stress resistance. -

Cost-Effective Alternative

– Longer service life reduces downtime and maintenance costs, making it a better investment than 304/316 stainless steel in harsh conditions.

Applications

-

Offshore & Marine Engineering – seawater cooling, shipbuilding, subsea pipelines.

-

Oil & Gas Industry – flow lines, risers, manifolds, process piping.

-

Power Generation – boiler systems, heat exchangers, condensers.

-

Chemical Processing – acid and chloride piping systems.

-

Desalination Plants – brine discharge, seawater intake, cooling loops.

Surface Finish: Pickled & Annealed

The pickled surface removes mill scale and impurities, while annealing restores ductility and corrosion resistance. Together, they ensure:

-

Smooth, clean surface for enhanced corrosion resistance.

-

Extended service life in aggressive environments.

-

Better performance during welding and installation.

Testing & Quality Assurance

Each ASTM A790 S32205 seamless pipe is subjected to strict quality control:

-

100% Heat Treatment (HT) to ensure correct duplex microstructure.

-

Ultrasonic Testing (UT) and Eddy Current Testing (ET) for defect detection.

-

Hydrostatic Testing for pressure integrity.

-

PMI (Positive Material Identification) for chemical composition verification.

-

Third-Party Inspection (SGS, BV, TUV) available upon request.

FAQ

Q1: Why choose ASTM A790 S32205 over 316L stainless steel?

A1: It has nearly 2× the strength and much better resistance to chloride stress corrosion cracking and pitting, making it more reliable in marine and chemical environments.

Q2: What does “Pickled & Annealed” mean?

A2: Pickling removes impurities, while annealing improves grain structure and corrosion resistance, resulting in a smooth and durable finish.

Q3: What is the importance of 100% HT?

A3: Heat treatment ensures a balanced duplex structure (ferrite + austenite), giving maximum strength, toughness, and corrosion protection.

Q4: Can DLSS provide third-party inspection?

A4: Yes, DLSS works with SGS, BV, TUV, and LR to provide full inspection and certification.

Why Choose DLSS?

-

Wide range of duplex & super duplex pipes and fittings.

-

Strict testing & inspection procedures to guarantee reliability.

-

Export expertise – supplied projects in over 40 countries.

-

Seaworthy packaging with capped ends, PE wrap, and wooden cases.