Introduction

The ASTM A182 F304 Forged Orifice Flange is a specialized stainless steel flange designed for precise flow measurement and control in piping systems. Manufactured to ASME B16.36, it incorporates an orifice plate between a pair of flanges to measure fluid or gas flow accurately.

DLSS supplied 3″ WNRF (Weld Neck Raised Face) Orifice Flanges, SCH40S, Class 600#, forged from A182 F304 stainless steel, for an end-user project with GE. This demonstrates DLSS’s capability to deliver high-performance components for critical industrial applications.

Key Features

-

Material: ASTM A182 F304 (Austenitic Stainless Steel)

-

Type: Weld Neck Raised Face Orifice Flange (WNRF)

-

Size: 3″ (DN80)

-

Wall Thickness: SCH40S

-

Pressure Rating: Class 600#

-

Standard: ASME B16.36 (Orifice Flanges)

-

Application: Flow measurement in industrial piping systems

-

End User: GE

Specifications

| Item | Details |

|---|---|

| Standard | ASTM A182 / ASME B16.36 |

| Material | Stainless Steel F304 |

| Type | Forged Flange – Weld Neck Raised Face Orifice (WNRF) |

| Size | 3″ (DN80) |

| Schedule | SCH40S |

| Pressure Rating | 600# |

| Surface | Machined, rust-preventive coating |

| End User | GE (General Electric) |

| Applications | Power plants, heat exchangers, chemical plants, flow monitoring systems |

Applications

-

Power Generation – used in steam, gas, and water piping systems to monitor and control flow (supplied to GE).

-

Oil & Gas Industry – accurate measurement of hydrocarbons and process fluids.

-

Chemical & Petrochemical – control of acids, gases, and corrosive media.

-

Industrial Piping Systems – integration into heat exchangers, boilers, and reactors.

Advantages of F304 Stainless Steel

-

Corrosion Resistance – effective against oxidation and general corrosive environments.

-

Strength & Durability – forged structure ensures reliability under high pressure (Class 600#).

-

Versatility – widely used in flow measurement systems across multiple industries.

-

Cost Efficiency – more economical than higher alloy grades, suitable for general service.

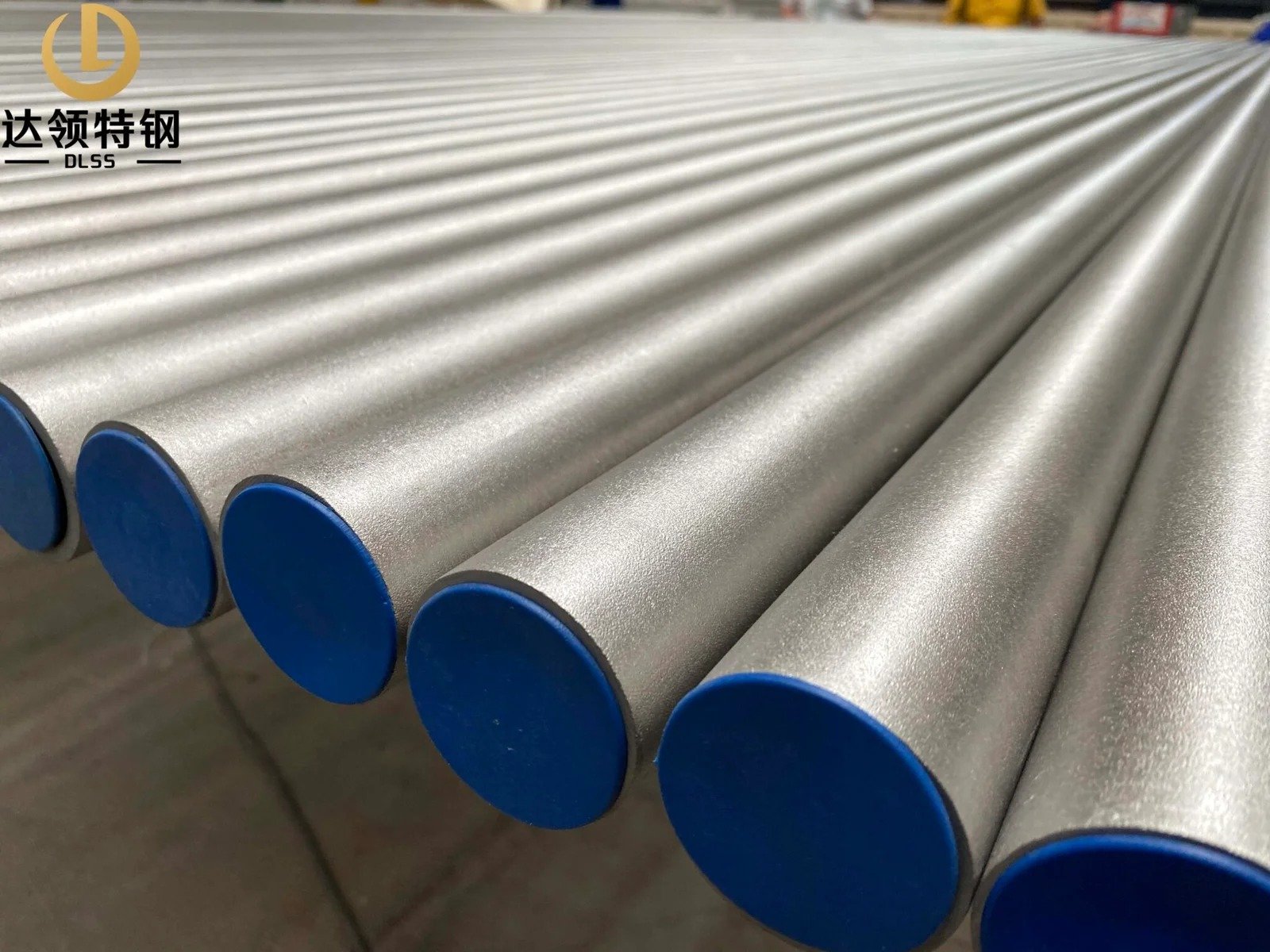

Why Choose DLSS?

-

Specialized supply of orifice flanges (ASME B16.36), forged fittings, and pipe accessories.

-

Strict Quality Control – PMI, UT, ET, Hydro, dimensional checks.

-

Third-Party Inspection – SGS, BV, TUV certifications available.

-

Export Packaging – plastic caps, PE wrap, ISPM-15 wooden cases.

-

Proven Track Record – supplied GE and other leading global end users with stainless steel flanges and fittings.