Introduction

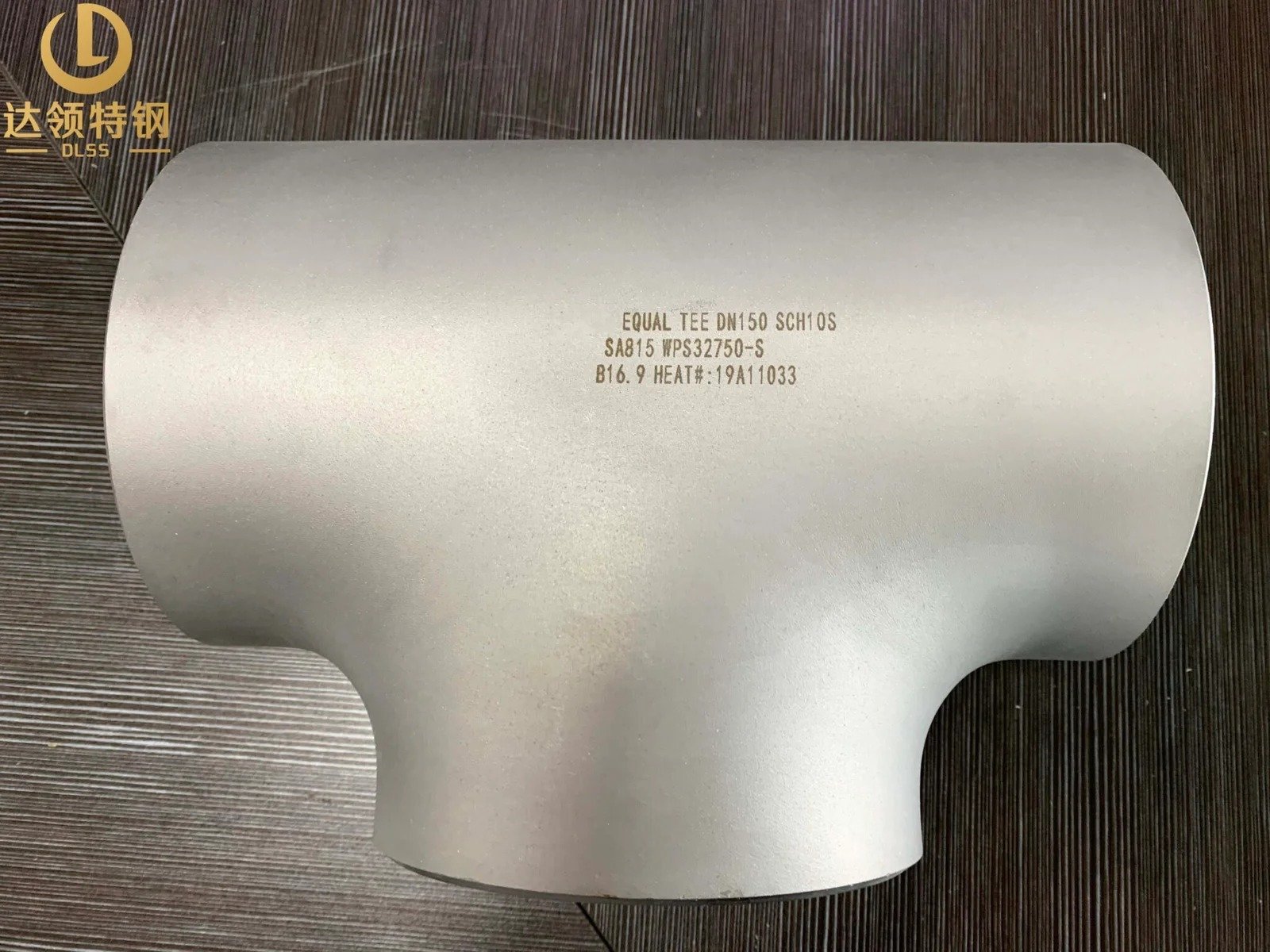

The ASTM A403 WP316L Stub End is a stainless steel pipe fitting designed for use with lap joint flanges, allowing for easy disassembly of piping systems. Manufactured from low-carbon austenitic stainless steel 316L, it offers superior resistance to chloride-induced corrosion, acids, and seawater environments, making it an ideal choice for oil & gas, marine, chemical, and power plant applications.

This product is a seamless (SMLS) stub end, available in DN150 and DN100 sizes, with Schedule 80S wall thickness, designed as Lap Joint Type A according to international standards.

Key Features

-

Material: ASTM A403 WP316L (Low-carbon stainless steel)

-

Type: Seamless Stub End (SMLS)

-

Design: Lap Joint, Type A

-

Size: DN150 / DN100

-

Schedule: SCH80S (heavy wall for high-pressure service)

-

Corrosion Resistance: Excellent in seawater, chlorides, and aggressive chemicals

-

Weldability: Low-carbon 316L grade minimizes carbide precipitation during welding

Specifications

| Item | Details |

|---|---|

| Standard | ASTM A403 |

| Material | Stainless Steel WP316L |

| Type | Seamless Stub End |

| Size | DN150 / DN100 |

| Schedule | SCH80S |

| Design | Lap Joint Type A |

| Applications | Offshore, Marine, Oil & Gas, Chemical Processing, Power Plants, Boilers |

Applications

-

Oil & Gas Industry – flow lines, manifolds, refinery piping.

-

Marine & Offshore – seawater cooling systems, desalination plants.

-

Chemical Plants – piping for acidic and chloride-rich environments.

-

Power Generation – boiler and heat exchanger piping.

-

Industrial Piping Systems – where frequent disassembly is required.

Advantages of WP316L

-

Superior Corrosion Resistance – molybdenum content improves resistance to pitting and crevice corrosion.

-

Low Carbon (L Grade) – prevents intergranular corrosion after welding.

-

Durable & Cost-Effective – long service life reduces maintenance costs.

-

Easy Installation & Replacement – lap joint design allows quick assembly/disassembly.

Why Choose DLSS?

-

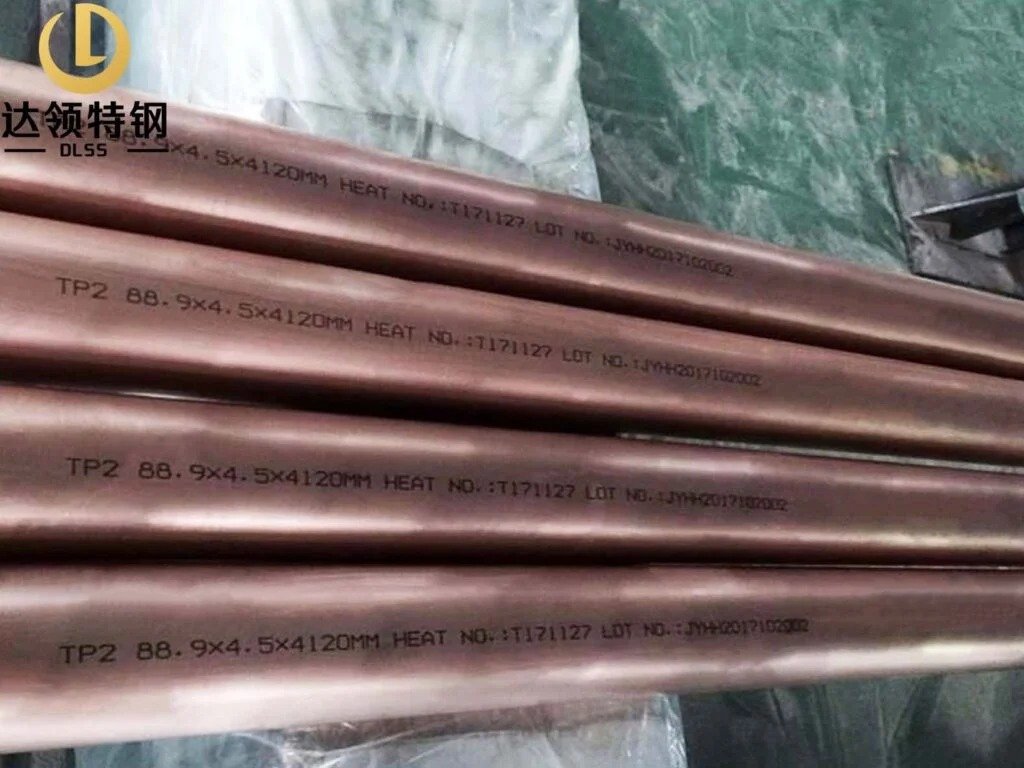

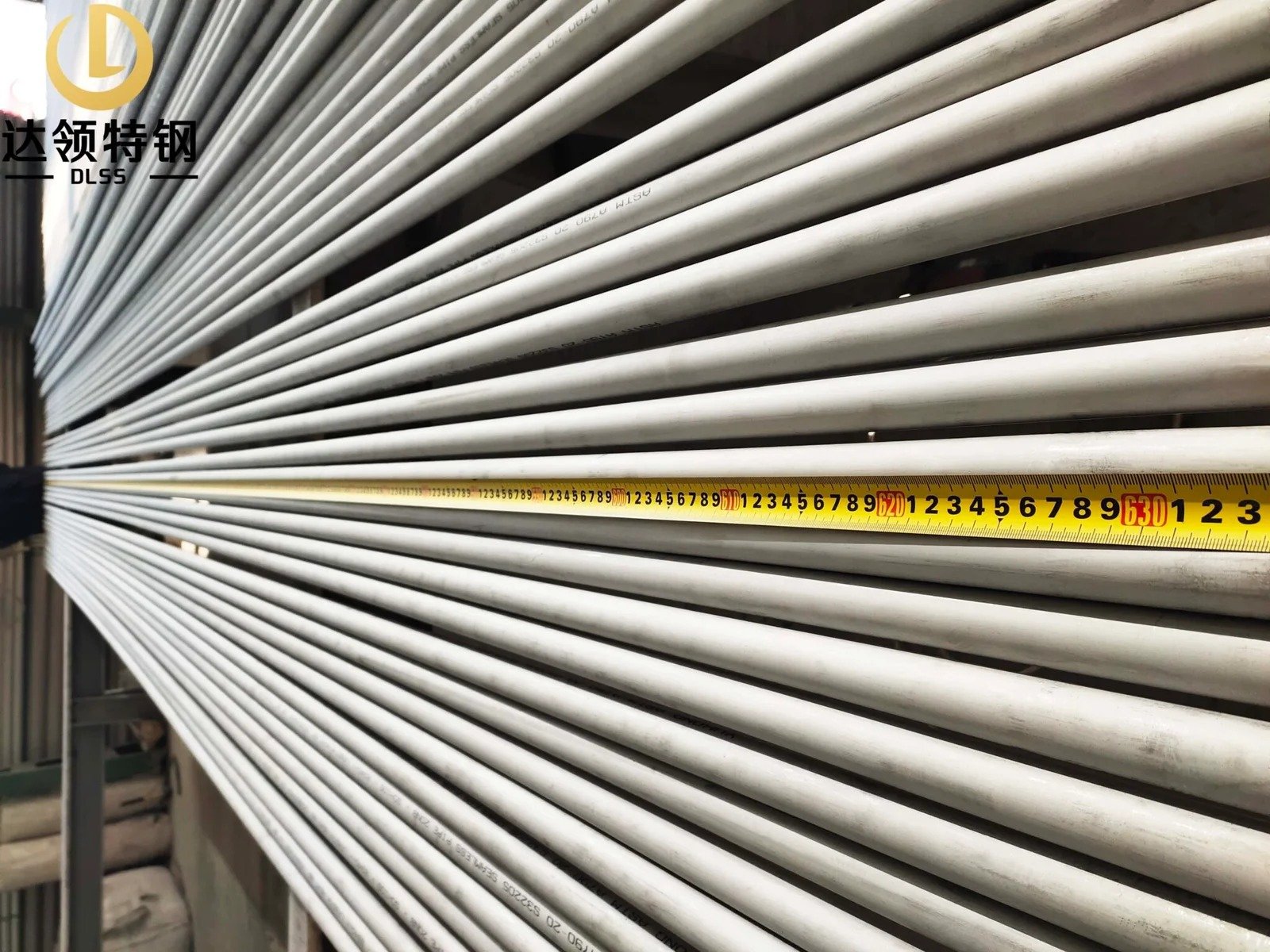

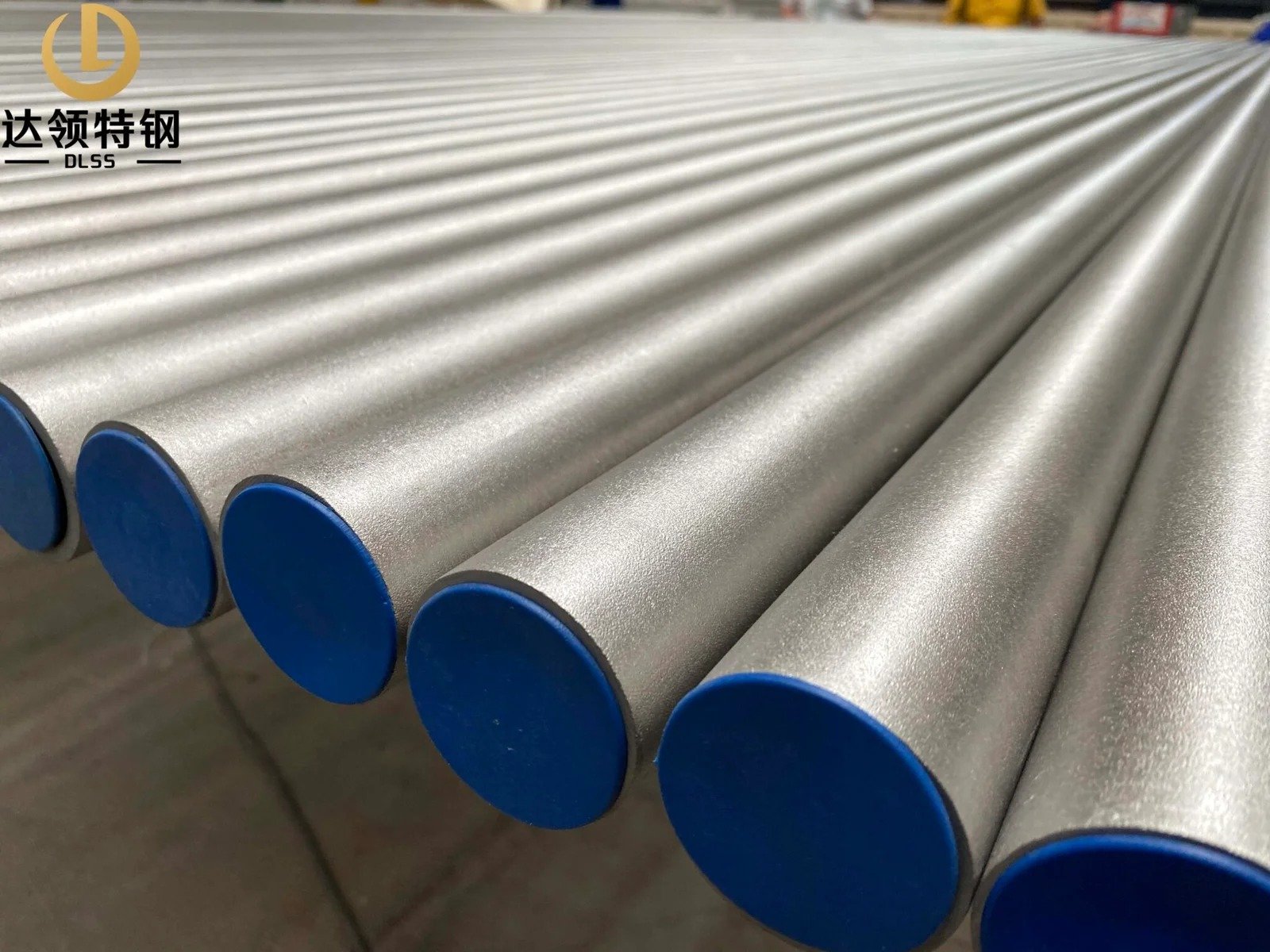

Supply of complete pipe fittings: stub ends, elbows, tees, reducers, flanges.

-

Strict Quality Control – PMI, Hydro, UT, ET, dimensional inspections.

-

Third-Party Inspection – SGS, BV, TUV, LR certifications available.

-

Export Packaging – PE caps, plastic wrapping, seaworthy wooden cases.

-

Global Experience – delivered stainless steel pipe fittings to power, petrochemical, and offshore projects worldwide.