Introduction

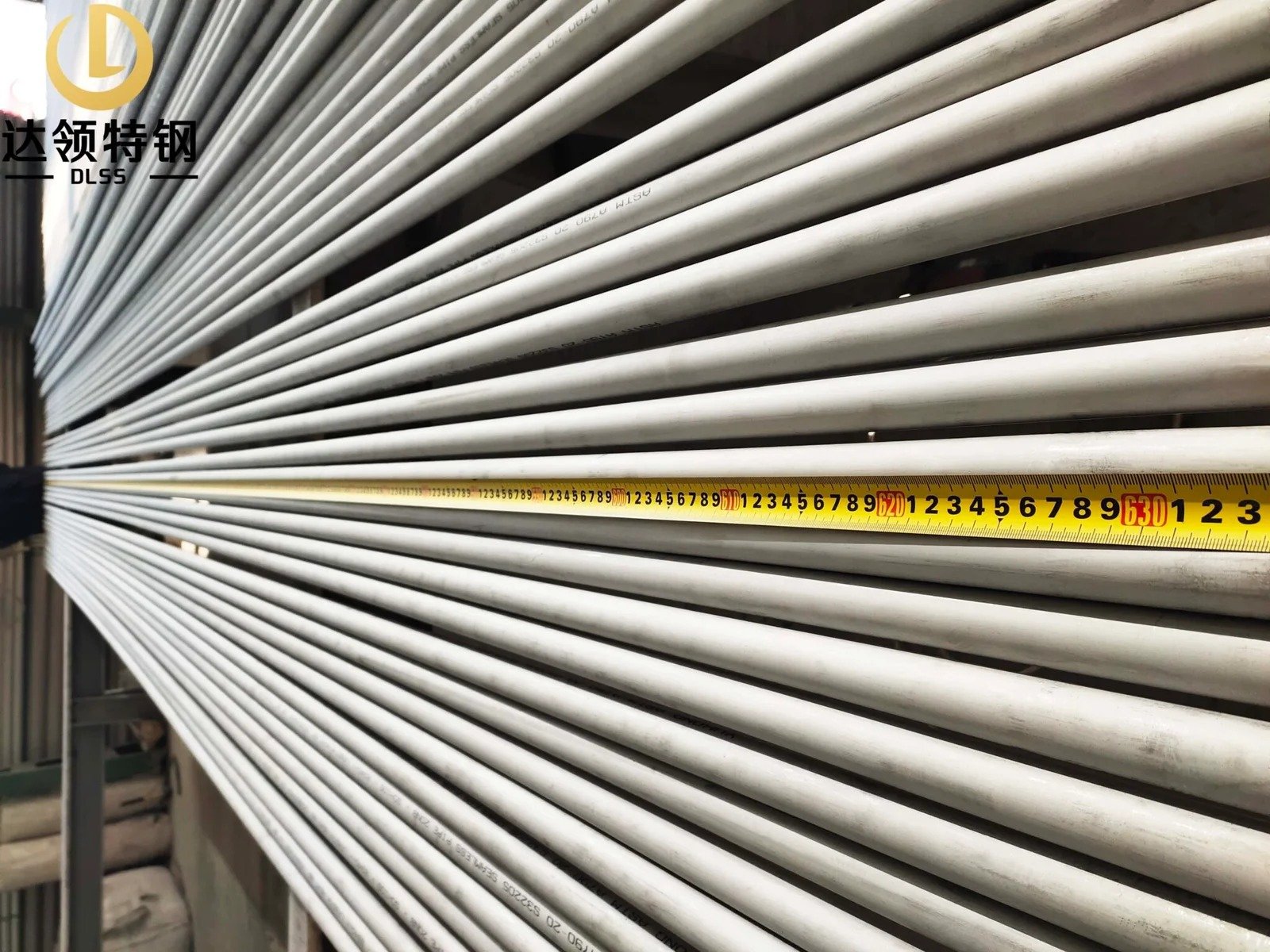

The ASTM A403 WP321 Seamless 180° Short Radius (SR) Elbow is a titanium-stabilized stainless steel pipe fitting designed for high-temperature and corrosive service conditions. With UNS S32100 (1.4541) as its base material, TP321 provides excellent resistance to intergranular corrosion and retains strength at elevated temperatures up to 870°C (1600°F).

This elbow is seamless (SMLS), with dimensions 88.9 mm OD and 3.05 mm minimum thickness at the middle of the bend, ensuring both structural integrity and flow efficiency. It is widely used in heat exchangers, boilers, refinery piping, and power generation plants.

Key Features

-

Material: ASTM A403 WP321 (Stainless Steel, UNS S32100 / 1.4541)

-

Type: Seamless 180° SR Elbow (Bend)

-

Size: 88.9 mm OD (3-1/2″)

-

Wall Thickness: 3.05 mm minimum at bend midsection

-

Radius: Short Radius (SR = 1D)

-

Standard: ASTM A403 / ASME B16.9

-

Properties: Titanium stabilized, high creep strength, resistant to intergranular corrosion

Specifications

| Item | Details |

|---|---|

| Standard | ASTM A403 / ASME B16.9 |

| Material | WP321 Stainless Steel (Ti-stabilized) |

| Type | Seamless 180° SR Elbow (Bend) |

| Size | 88.9 mm OD |

| Min. Thickness | 3.05 mm at bend middle |

| Radius | Short Radius (SR = 1D) |

| Applications | Heat Exchangers, Boilers, Refinery Piping, Power Plants, Petrochemical |

Advantages of TP321

-

Titanium Stabilization – prevents carbide precipitation and intergranular corrosion after welding.

-

High Temperature Resistance – performs well in continuous service up to 870°C.

-

Oxidation Resistance – suitable for high-heat and cyclic conditions.

-

Strength & Reliability – seamless construction with controlled wall thickness.

-

Versatility – widely used in critical piping systems requiring both corrosion and heat resistance.

Applications

-

Heat Exchangers – for hot fluid circulation.

-

Boilers & Superheaters – withstands high pressure and high temperature.

-

Refineries & Petrochemicals – piping exposed to hot hydrocarbons and gases.

-

Power Generation – condenser and steam piping.

-

Industrial Furnaces – resistant to scaling in thermal cycles.

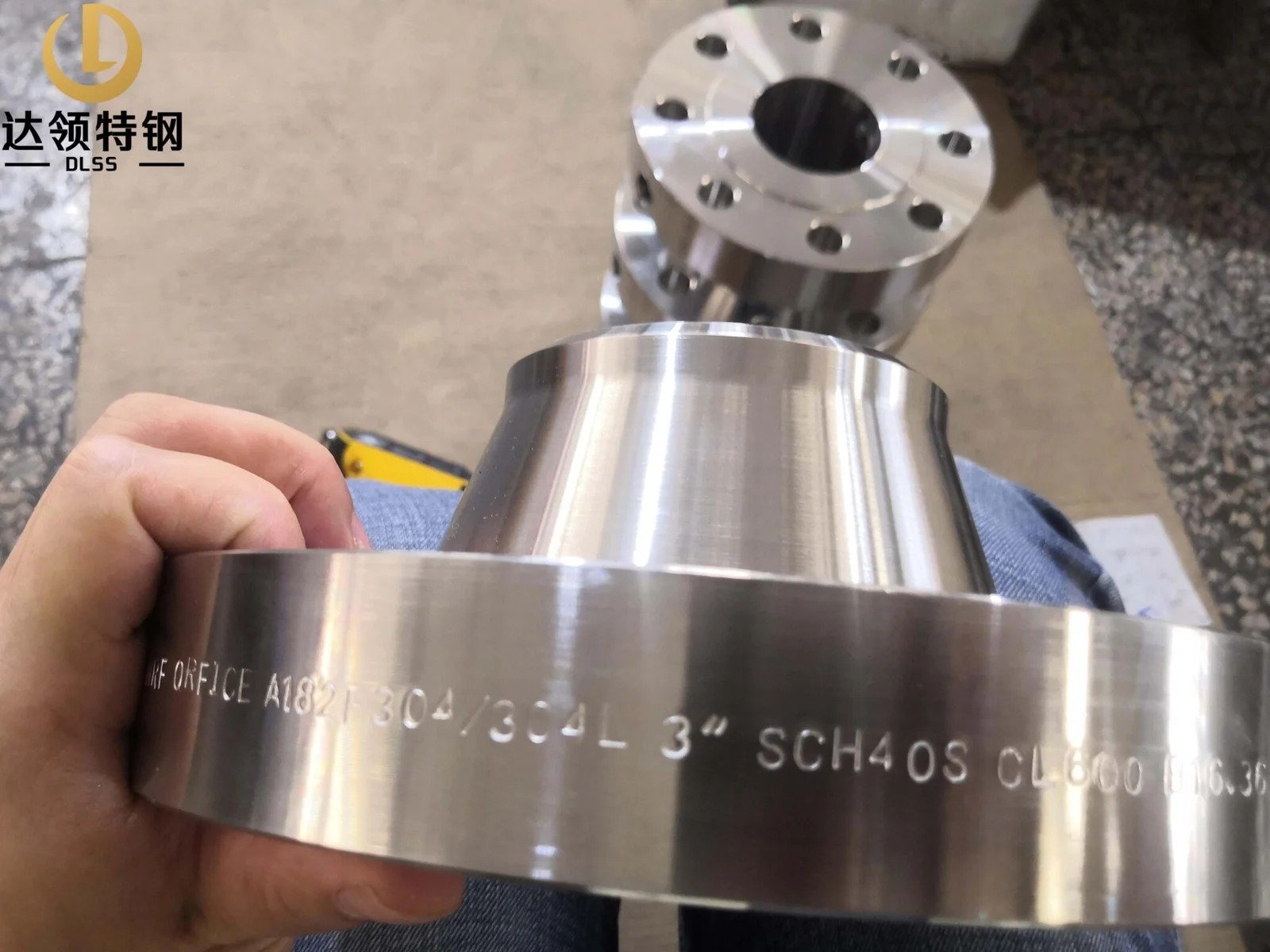

Quality Assurance

DLSS ensures strict compliance with international standards:

-

Dimensional Inspection – tight tolerance control.

-

PMI Testing – verifies correct TP321 grade.

-

NDT (UT, ET) – ensures defect-free structure.

-

Hydrostatic Testing – available upon request.

-

Third-Party Inspection – SGS, BV, TUV, LR available.