Introduction

The ASTM A312 TP321 Seamless Pipe is a titanium-stabilized austenitic stainless steel pipe engineered for high-temperature and corrosive service. With the addition of titanium (Ti), TP321 provides superior resistance to intergranular corrosion after welding and excellent creep strength at elevated temperatures.

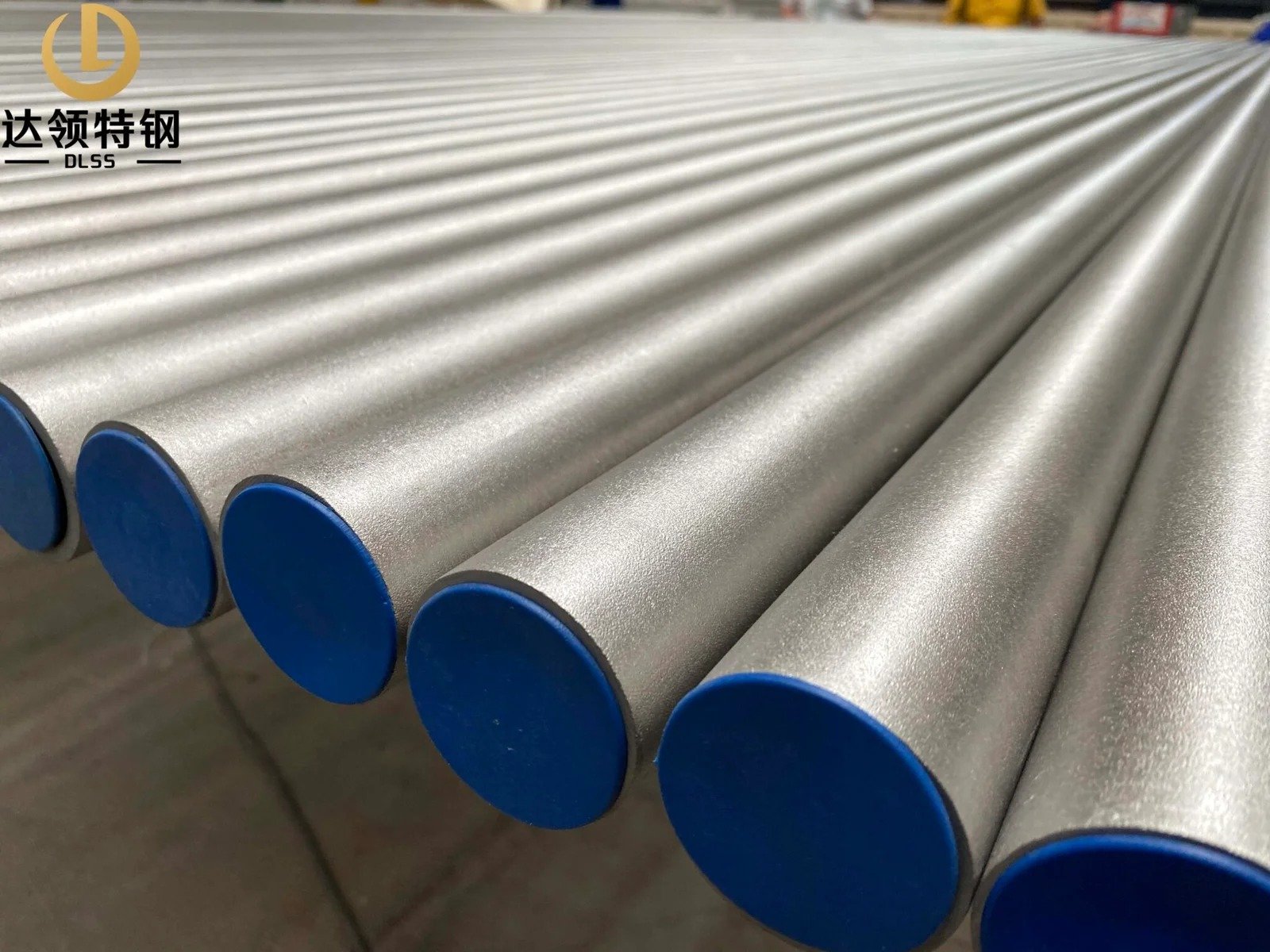

DLSS supplied 114.3 mm OD × 3.20 mm WT × 9200 mm length seamless pipes, manufactured in compliance with ASTM A312, and fully tested with 100% heat treatment (HT) and 100% eddy current testing (ET), making them highly reliable for heat exchanger applications.

Key Features

-

Material: Stainless Steel TP321 (UNS S32100 / 1.4541)

-

Standard: ASTM A312

-

Type: Seamless Pipe (SMLS)

-

Size: 114.3 mm OD × 3.20 mm WT × 9200 mm Length

-

Testing: 100% HT + 100% ET for structural and surface integrity

-

Surface Condition: Smooth finish for industrial use

-

Application: Heat exchangers, boilers, petrochemical and power plants

Specifications

| Item | Details |

|---|---|

| Standard | ASTM A312 |

| Material | TP321 Stainless Steel (Ti-stabilized) |

| Type | Seamless Pipe |

| Size | 114.3×3.20×9200MM |

| Testing | 100% HT + 100% ET |

| Applications | Heat Exchangers, Boilers, Refinery Piping, Power Generation, Chemical Plants |

Advantages of TP321

-

Titanium Stabilization – prevents carbide precipitation and intergranular corrosion.

-

High Temperature Resistance – stable in continuous service up to 870°C (1600°F).

-

Oxidation & Scaling Resistance – suitable for cyclic heating applications.

-

Reliable Strength – creep and stress rupture resistance superior to 304/316 grades.

-

Tested Integrity – 100% HT + 100% ET ensures safety in critical heat exchanger systems.

Applications

-

Heat Exchangers – for hot fluids and gases.

-

Boilers & Superheaters – long-length piping with reliable weldability.

-

Petrochemical Plants – refinery and catalytic equipment service.

-

Power Generation – piping for steam, condensers, and auxiliary systems.

-

Industrial Furnaces – components exposed to high-temperature cycles.

Quality Assurance

DLSS guarantees every pipe meets stringent quality standards:

-

100% Heat Treatment (HT) – ensures balanced microstructure and durability.

-

100% Eddy Current Testing (ET) – detects surface flaws and defects.

-

PMI Testing – verifies correct grade TP321.

-

Hydrostatic & Dimensional Testing – available on request.

-

Third-Party Inspection – SGS, BV, TUV, LR certification supplied if required.

FAQ

Q1: Why choose TP321 instead of TP304 for heat exchangers?

A1: TP321 includes titanium stabilization, which prevents intergranular corrosion after welding and offers better high-temperature strength.

Q2: What is the role of HT and ET?

A2: HT (Heat Treatment) ensures structural stability, while ET (Eddy Current Testing) guarantees defect-free surfaces.

Q3: Can DLSS supply long-length pipes like 9200 mm?

A3: Yes, DLSS manufactures custom lengths up to 12 meters to meet client specifications.

Why Choose DLSS?

-

30+ years of experience in stainless steel seamless pipes.

-

Strong track record in supplying tubes and pipes for global heat exchanger projects.

-

Comprehensive QC and certification in line with ASTM/ASME standards.

-

Seaworthy packaging with plastic caps, PE wrap, and ISPM-15 wooden cases.