Introduction

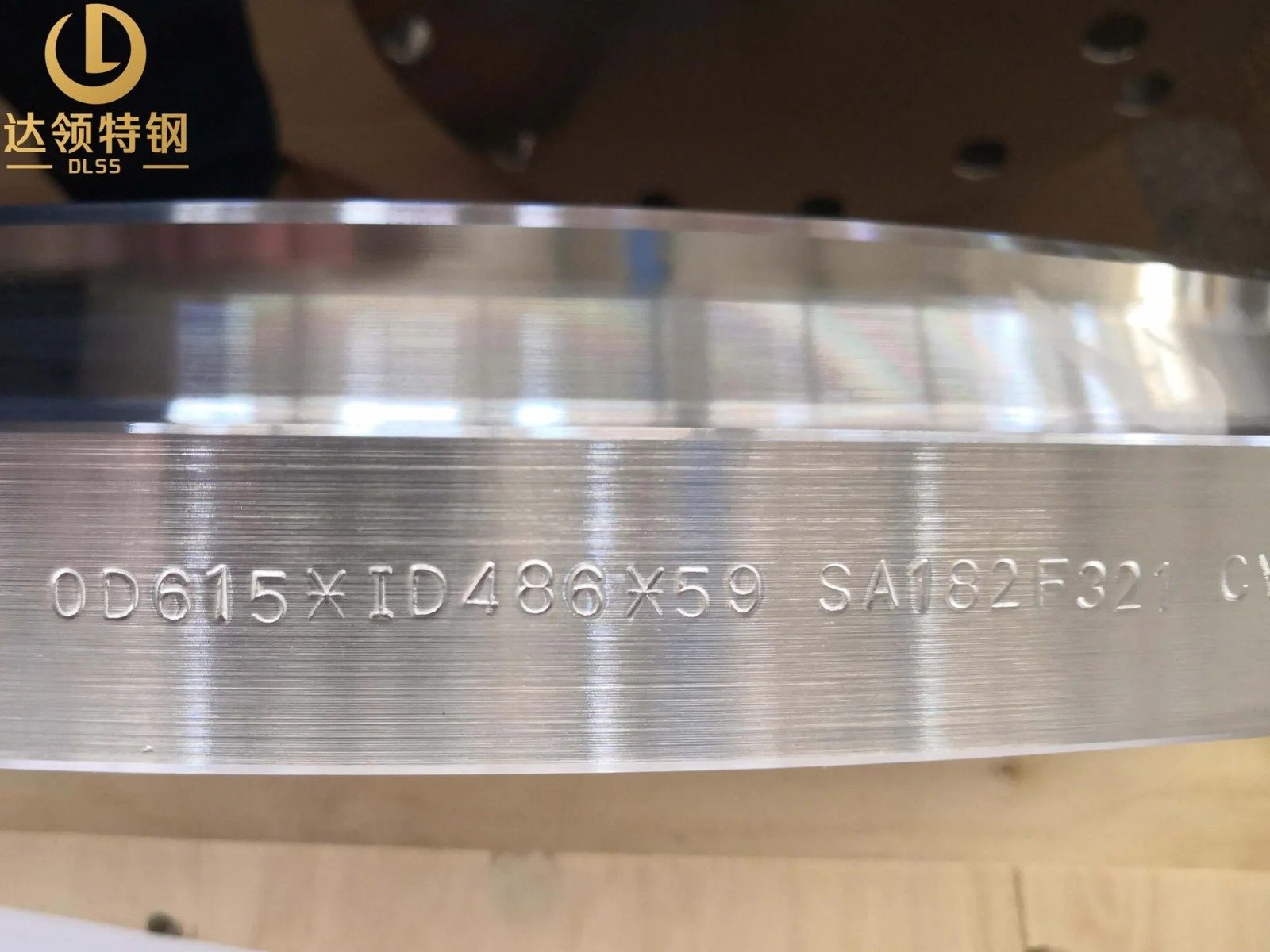

The ASME SA182 F304 Forged Flange is a high-quality stainless steel flange designed for reliable performance in heat exchanger factories and process piping systems. Made from austenitic stainless steel 304, it provides excellent resistance to oxidation, corrosion, and moderate chloride environments.

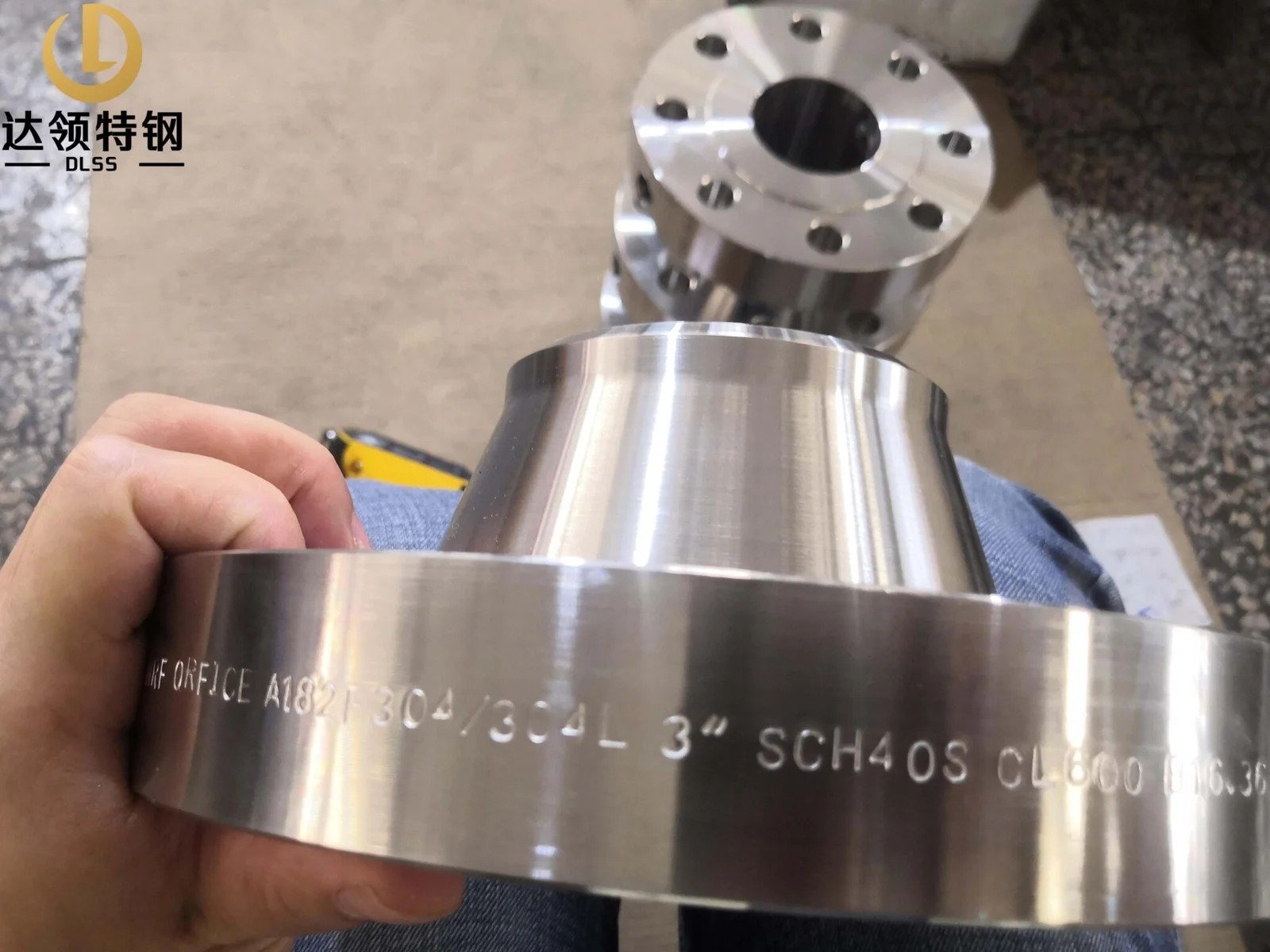

This flange type is Long Weld Neck Raised Face (LWNRF), designed for high-temperature and high-pressure applications, making it especially suitable for boilers, pressure vessels, and heat exchangers. DLSS supplied the 2″ size, length 310 mm, pressure class 150#, ASME B16.5 compliant for international projects.

Key Features

-

Material: ASME SA182 F304 (Austenitic Stainless Steel)

-

Type: Long Weld Neck Raised Face Flange (LWNRF)

-

Size: 2″ (DN50)

-

Length: 310 mm

-

Pressure Rating: Class 150#

-

Standard: ASME B16.5

-

Manufacturing Process: Forged for strength and reliability

-

Application: Designed for heat exchangers, boilers, and pressure systems

Specifications

| Item | Details |

|---|---|

| Standard | ASME SA182 / ASME B16.5 |

| Material | Stainless Steel F304 |

| Type | Forged Flange – Long Weld Neck Raised Face (LWNRF) |

| Size | 2″ (DN50) |

| Length | 310 mm |

| Pressure Rating | 150# |

| Surface | Machined, rust-preventive coating |

| Applications | Heat Exchanger Factory, Boilers, Pressure Vessels, Chemical Plants |

Applications

-

Heat Exchanger Factories – secure pipe-to-equipment connections.

-

Boilers & Pressure Vessels – withstands high pressure and temperature.

-

Chemical Processing Plants – resistant to moderate corrosive environments.

-

Power Plants – piping systems with high performance demand.

-

General Industrial Piping – versatile use in fluid and gas transport.

Advantages of F304 Stainless Steel

-

Corrosion Resistance – good resistance to oxidation and most corrosive media.

-

Weldability – excellent performance during fabrication and installation.

-

Strength & Durability – forged structure ensures reliable long-term use.

-

Cost-Effective – widely available and economical compared to higher alloy grades.

Why Choose DLSS?

-

Full range of forged flanges: WN, LWNRF, SO, BL, TH, SW, Lap Joint.

-

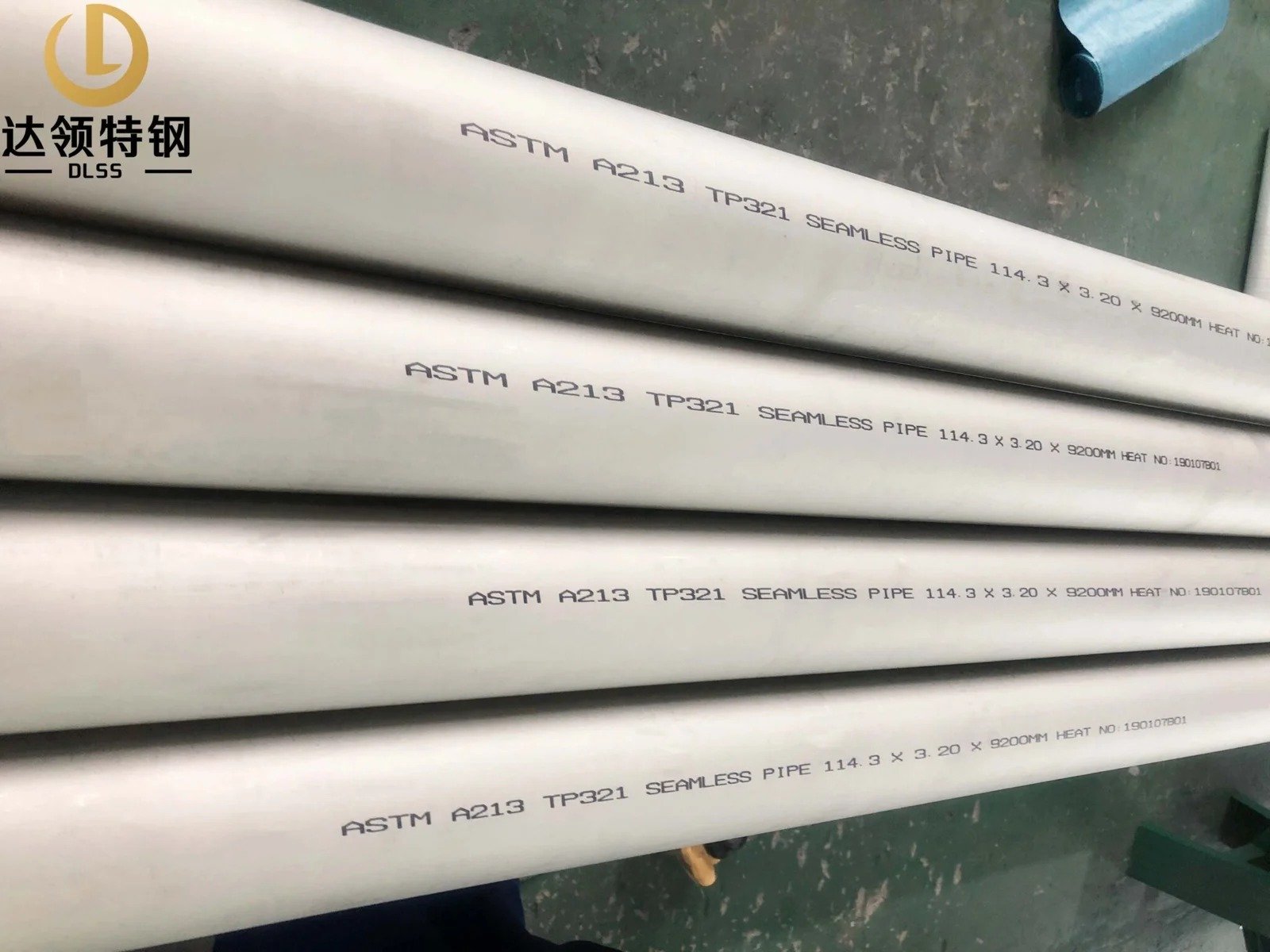

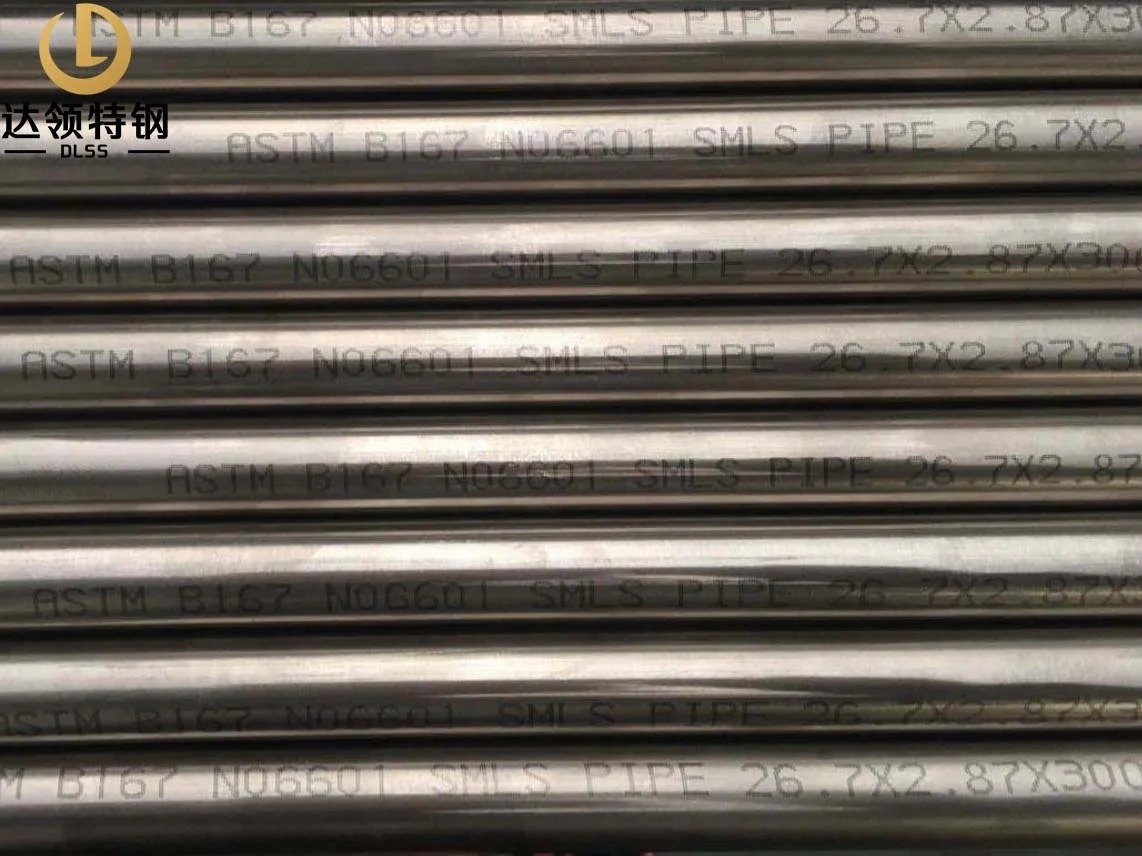

Strict Quality Control – PMI, UT, ET, Hydro testing, dimensional check.

-

Third-Party Inspection – SGS, BV, TUV certifications available.

-

Export Packaging – plastic caps, PE wrap, ISPM-15 wooden cases.

-

Global Supply Experience – supplied flanges to power, petrochemical, and heat exchanger manufacturers worldwide.