Introduction

ASME SA182 F53 Forged Flange (UNS S32750) is a super duplex stainless steel flange offering outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking, while providing twice the strength of standard austenitic stainless steels.

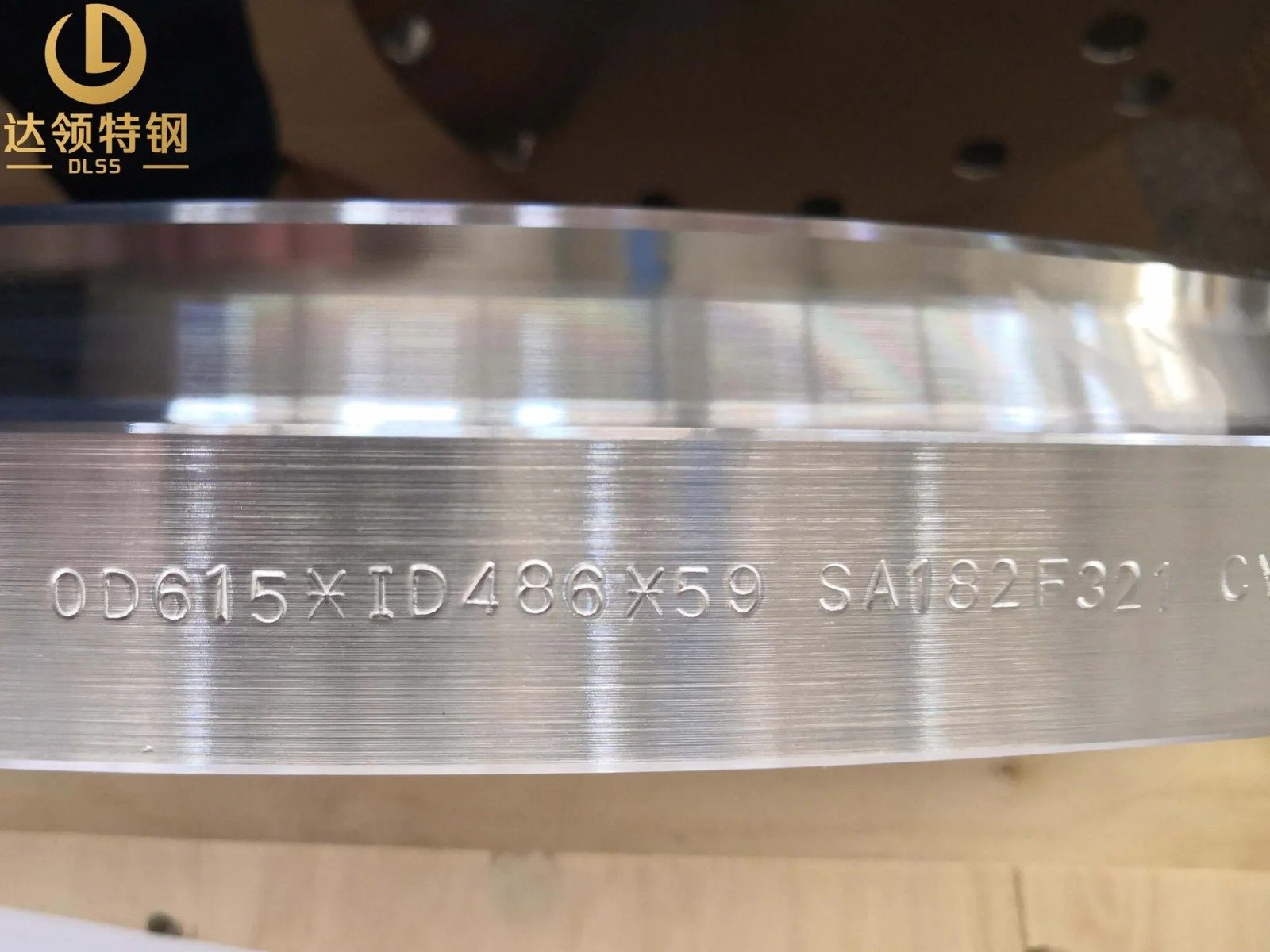

DLSS supplied a batch of Weld Neck Flat Face (WNFF) flanges, 6″, SCH40, CL150, manufactured to ASME SA182 and dimensionally compliant with ASME B16.5, exported to New Zealand for a project requiring reliable performance in marine and chemical service environments.

Key Features

-

Material: ASME SA182 F53 (UNS S32750, Super Duplex Stainless Steel)

-

Type: Weld Neck Forged Flange (WNFF)

-

Size: 6″ (DN150)

-

Schedule: SCH40

-

Pressure Class: CL150

-

Standard: ASME B16.5

-

Surface: Machined / Rust Preventive Coated

-

Strength: Yield strength ≈ 550 MPa (about 2× that of 316L)

-

Corrosion Resistance: Excellent against chlorides, seawater, and aggressive chemicals

Specifications

| Item | Details |

|---|---|

| Standard | ASME SA182 / ASME B16.5 |

| Material | Super Duplex Stainless Steel F53 (UNS S32750) |

| Type | Weld Neck Forged Flange (WNFF) |

| Size | 6″ (DN150) |

| Schedule | SCH40 |

| Pressure Class | CL150 |

| Destination | New Zealand |

| Applications | Offshore, Marine, Oil & Gas, Chemical Plants, Power Generation |

Applications

-

Offshore Platforms & Subsea Pipelines – high chloride resistance.

-

Marine Engineering – seawater cooling and desalination systems.

-

Oil & Gas Industry – risers, manifolds, and process piping.

-

Chemical & Petrochemical Plants – acid and chloride-rich process units.

-

Power Generation – heat exchangers and high-pressure piping systems.

Why Choose F53 Super Duplex?

-

High Strength – nearly double that of standard stainless steel (304/316).

-

Superior Corrosion Resistance – resists pitting (PREN > 40) and chloride SCC.

-

Cost-Effective – replaces more expensive nickel alloys in many applications.

-

Extended Service Life – reliable in seawater, brine, and aggressive environments.

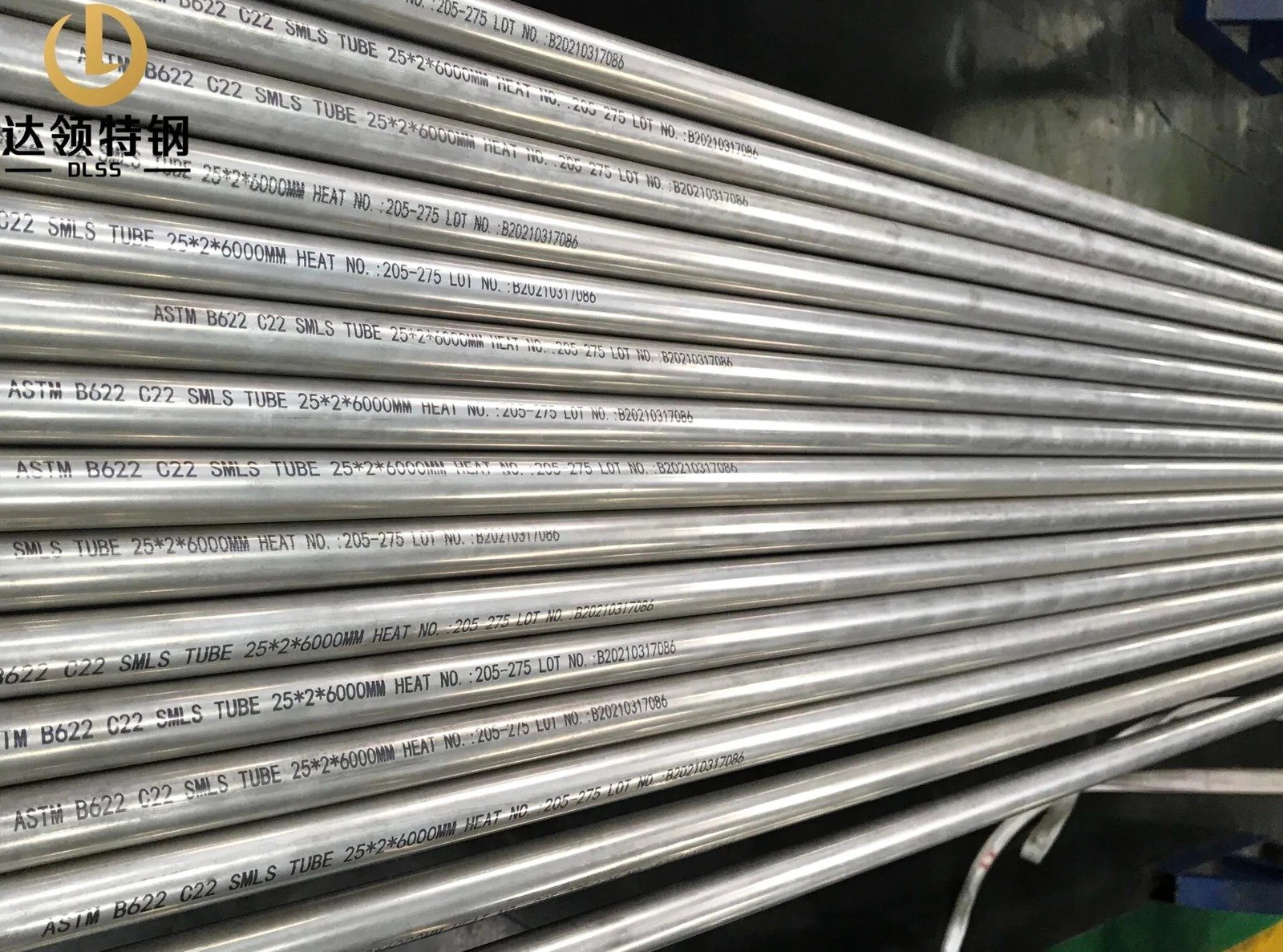

Why Choose DLSS?

-

Expertise in super duplex flanges and fittings: F53 (S32750), F55 (S32760).

-

Strict Quality Assurance – PMI, UT, ET, Hydro, Dimensional Checks.

-

Third-Party Certification – SGS, BV, TUV available.

-

Export Packaging – seaworthy cases with anti-rust protection.

-

Global Projects – long-term supply to New Zealand, Australia, Middle East, Europe.