Introduction

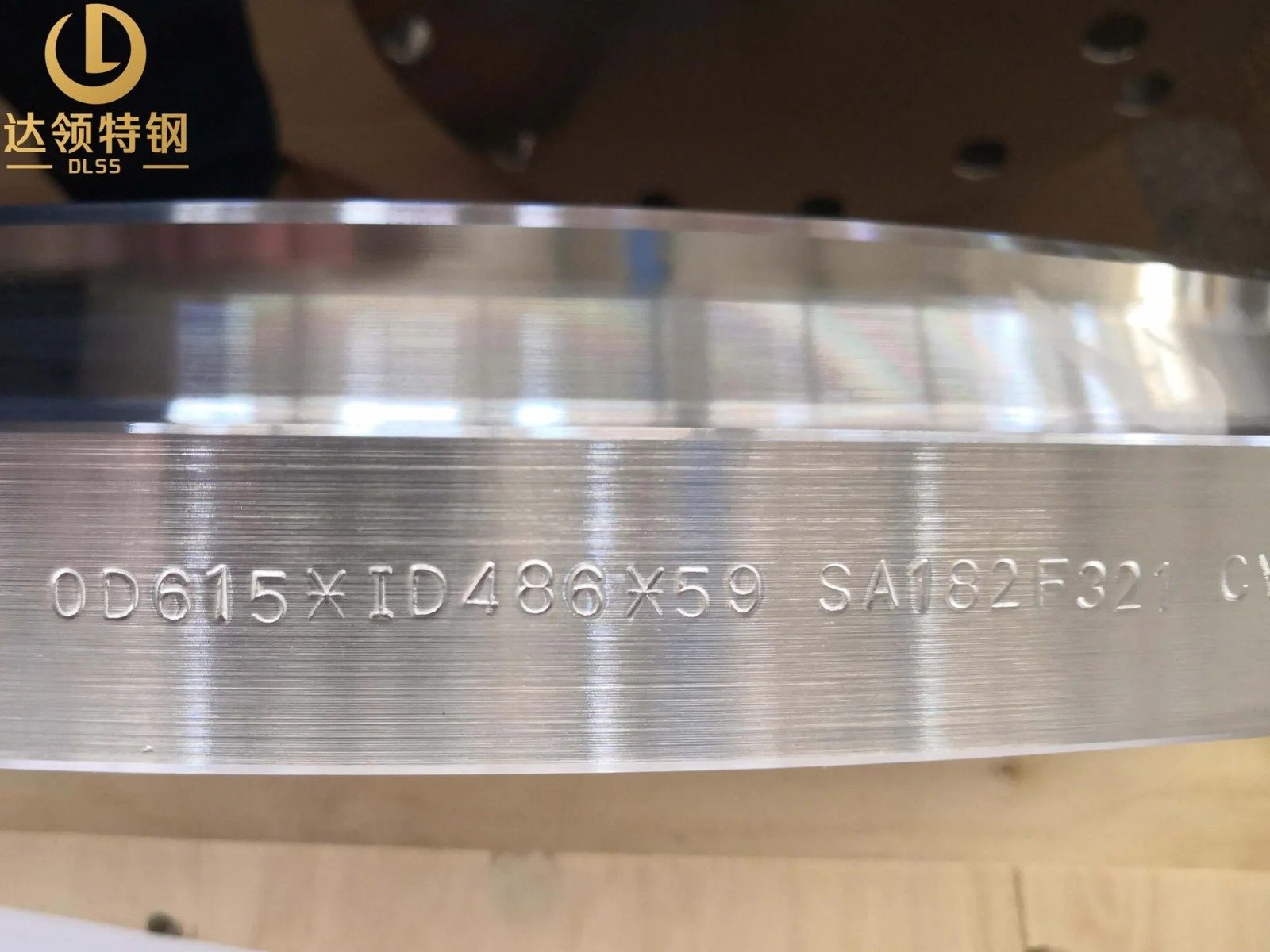

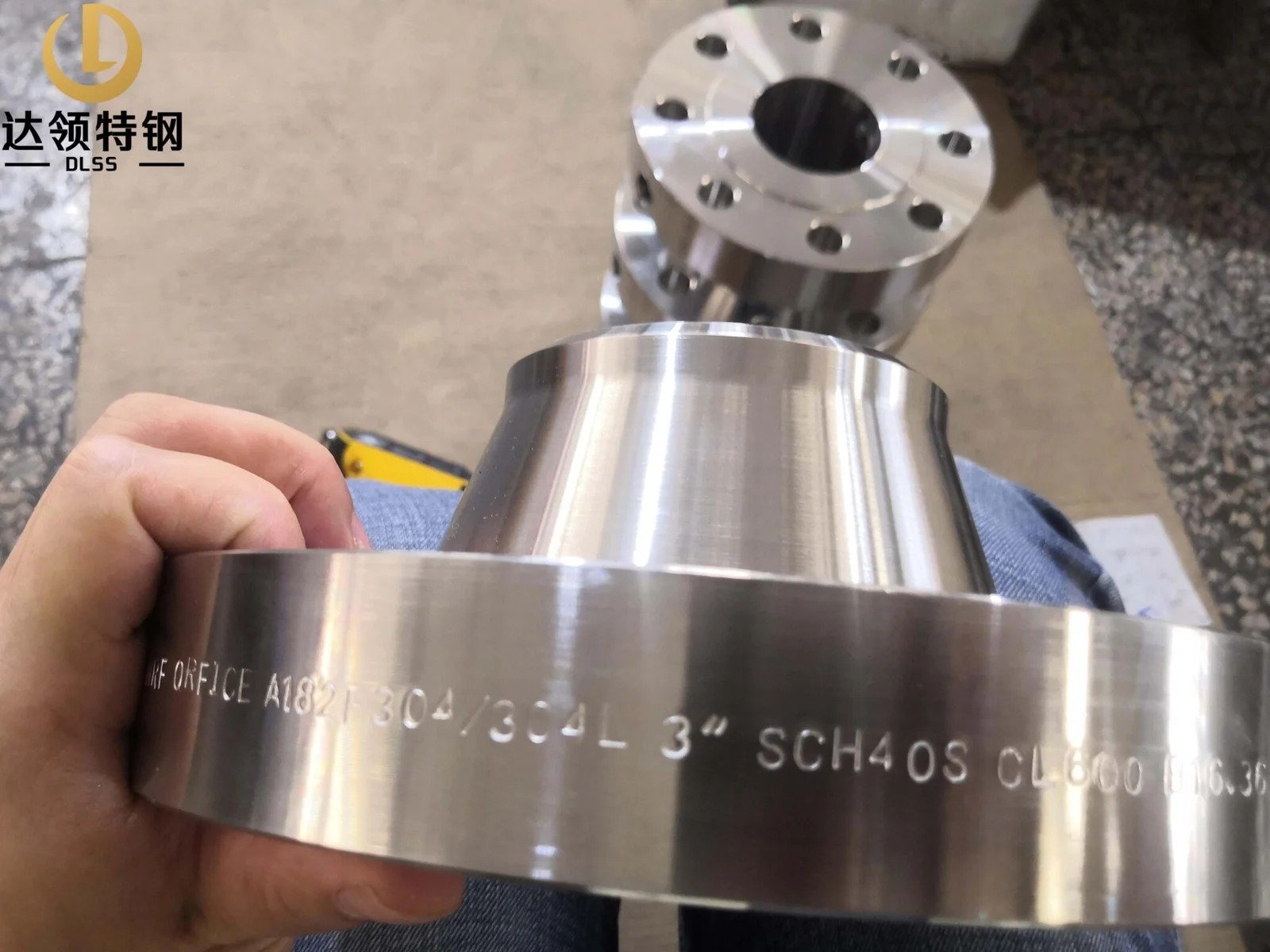

ASTM A/ASME SA182 F60 Forged Flange (UNS S32205) is a duplex stainless steel flange that combines high strength with excellent resistance to chloride stress corrosion cracking, pitting, and crevice corrosion.

DLSS has supplied Weld Neck Flat Face (WNFF) flanges, DN50, thickness 10 mm, manufactured according to ASTM A/ASME SA182 F60 and AS2129 Table E, exported to Australia for piping systems in marine, offshore, and chemical industries.

Key Features

-

Material: ASTM A/ASME SA182 F60 (Duplex Stainless Steel, UNS S32205)

-

Type: Weld Neck Forged Flange (WNFF)

-

Standard: AS2129 Table E (Australian Standard)

-

Size: DN50

-

Thickness: 10 mm

-

Strength: Yield strength ≈ 450 MPa (higher than 316L)

-

Corrosion Resistance: Excellent in seawater and chloride-rich service

-

Face Type: Flat Face (FF)

Specifications

| Item | Details |

|---|---|

| Standard | ASTM A/ASME SA182 / AS2129 Table E |

| Material | Duplex Stainless Steel F60 (UNS S32205) |

| Type | Weld Neck Forged Flange (WNFF) |

| Size | DN50 |

| Thickness | 10 mm |

| Pressure Rating | Table E (≈ CL150 equivalent) |

| Destination | Australia |

| Applications | Offshore, Marine, Oil & Gas, Chemical Plants, Power Generation |

Applications

-

Marine & Offshore Projects – seawater cooling, risers, subsea piping.

-

Oil & Gas Industry – pipelines and process systems in chloride environments.

-

Chemical Processing – acid and chloride service reactors and scrubbers.

-

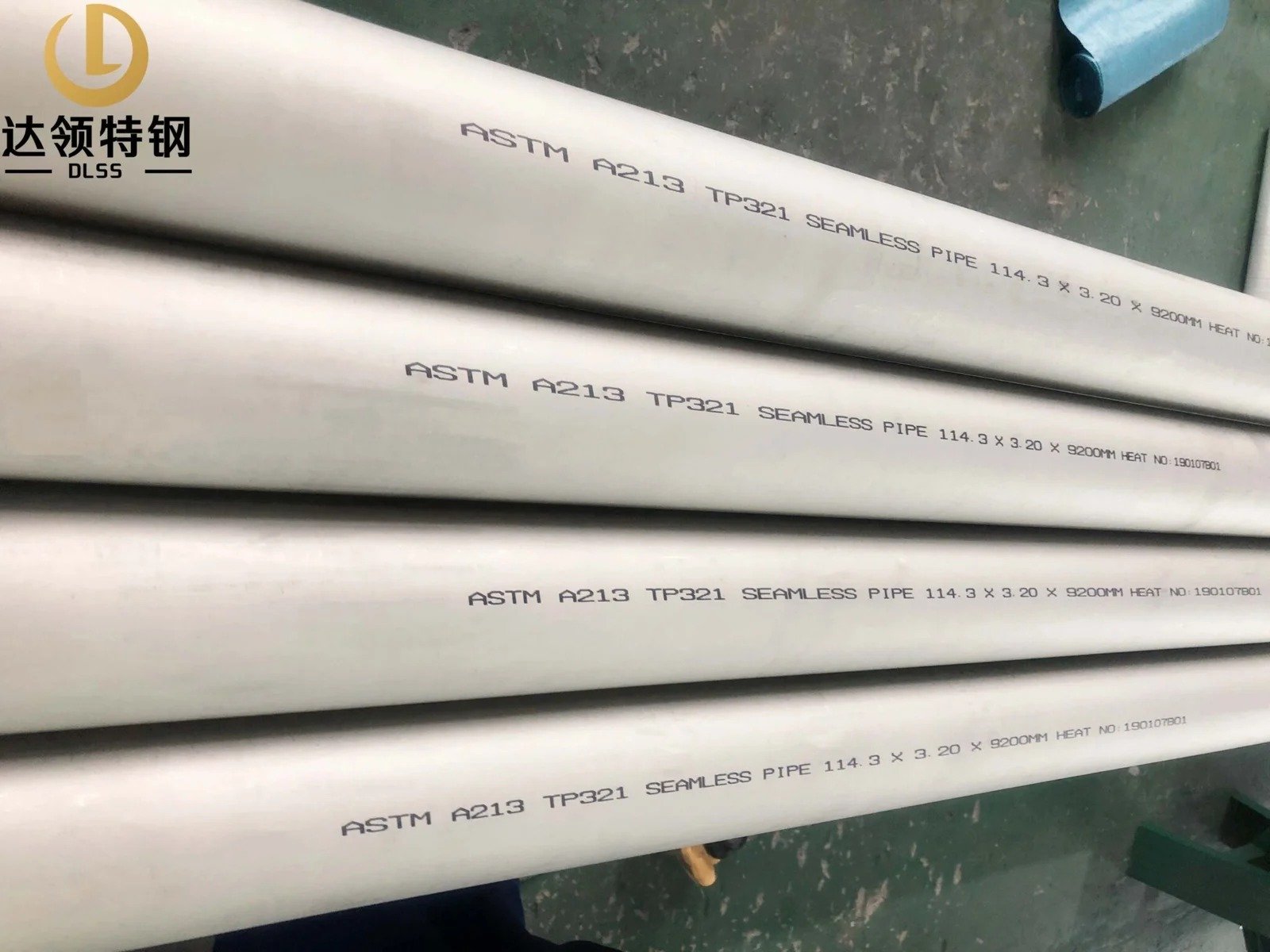

Power Plants – boiler, condenser, and heat exchanger piping.

-

Water Treatment – desalination and brine discharge systems.

Why Choose Duplex F60 (S32205)?

-

High Strength – yield strength nearly double that of 316L stainless steel.

-

Chloride Resistance – strong resistance to pitting and SCC in seawater.

-

Cost-Effective – durable alternative to nickel alloys in many applications.

-

Balanced Microstructure – combines toughness and corrosion resistance.

Why Choose DLSS?

-

Full range of duplex and super duplex flanges: F51 (S31803), F53 (S32750), F55 (S32760).

-

Strict Testing – PMI, UT, ET, Hydro, dimensional inspections.

-

Third-Party Approval – SGS, BV, TUV certification available.

-

Export Expertise – ISPM-15 seaworthy packaging and fast delivery to Australia.

-

Proven Track Record – supplied duplex piping solutions for offshore, desalination, and energy projects.