Introduction

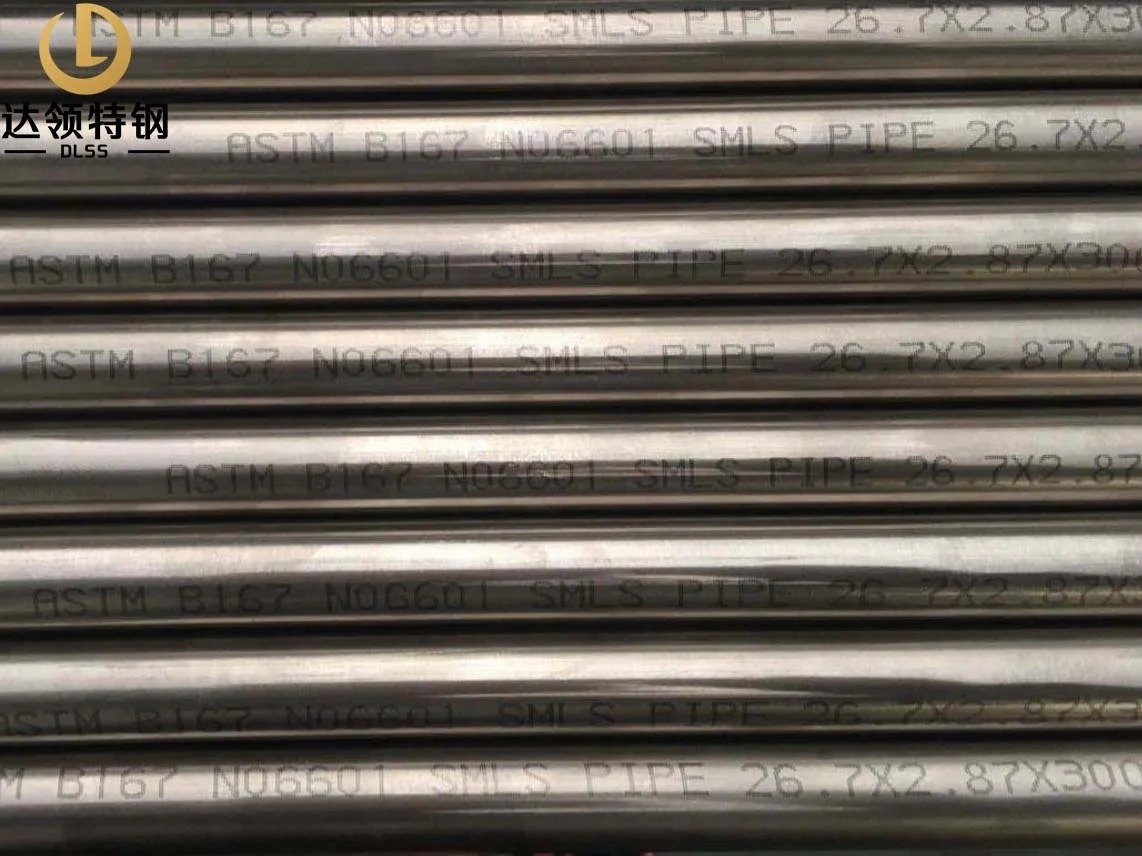

The ASME SA213 TP304 Seamless Tube is one of the most widely used stainless steel tubes for heat exchangers, condensers, and boilers. As a classic 18/8 austenitic stainless steel (18% Cr, 8% Ni), TP304 offers an excellent balance of strength, corrosion resistance, and cost efficiency, making it suitable for diverse industrial applications.

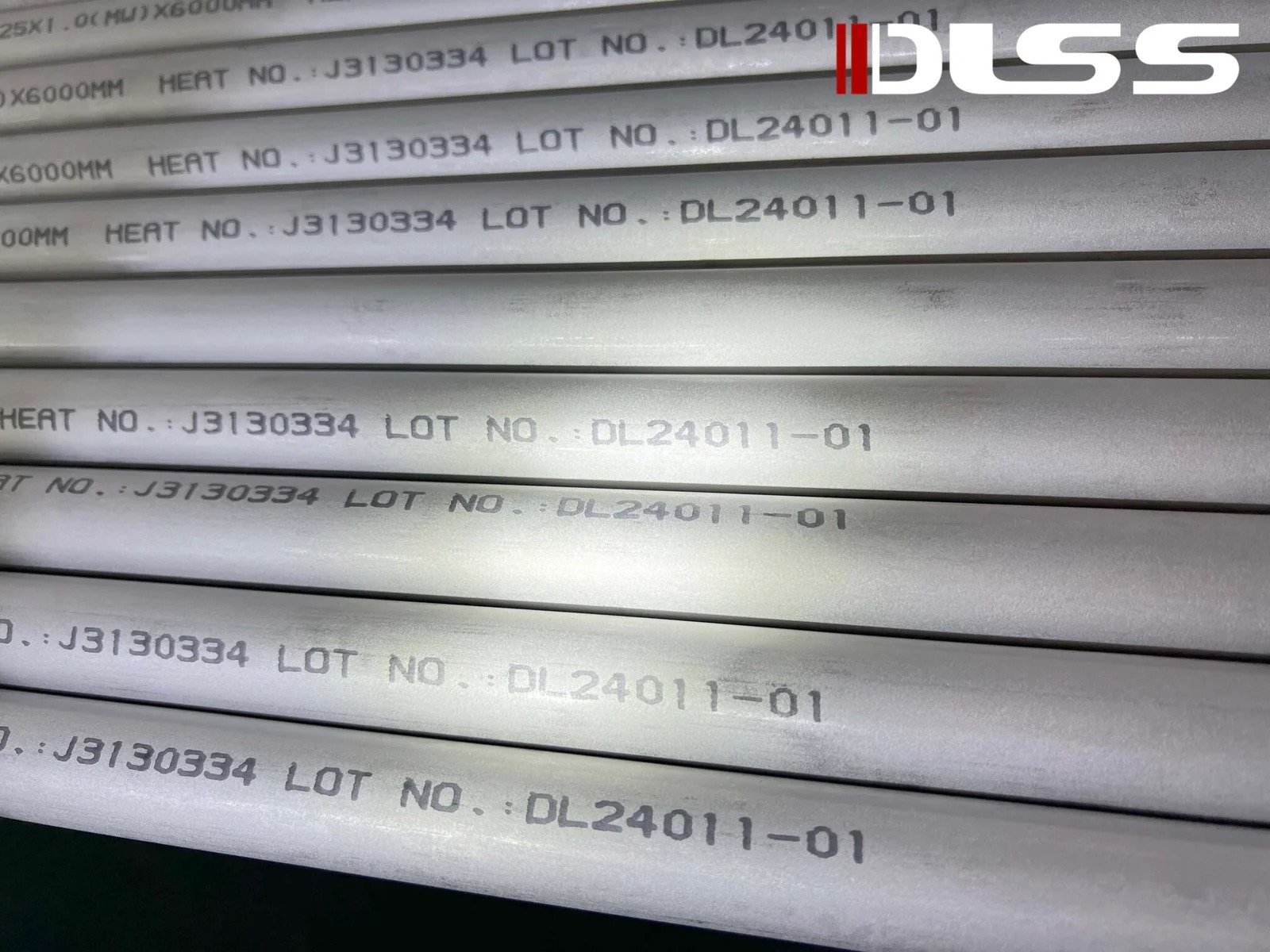

DLSS supplies 25 mm OD × 1.0 mm minimum wall × 6000 mm length tubes, manufactured to ASME SA213. Each tube undergoes 100% Heat Treatment (HT), 100% Eddy Current Testing (ET), and 100% Ultrasonic Testing (UT), ensuring reliability and safety in critical heat exchanger service.

Key Features

-

Material: TP304 Stainless Steel (UNS S30400 / 1.4301)

-

Standard: ASME SA213

-

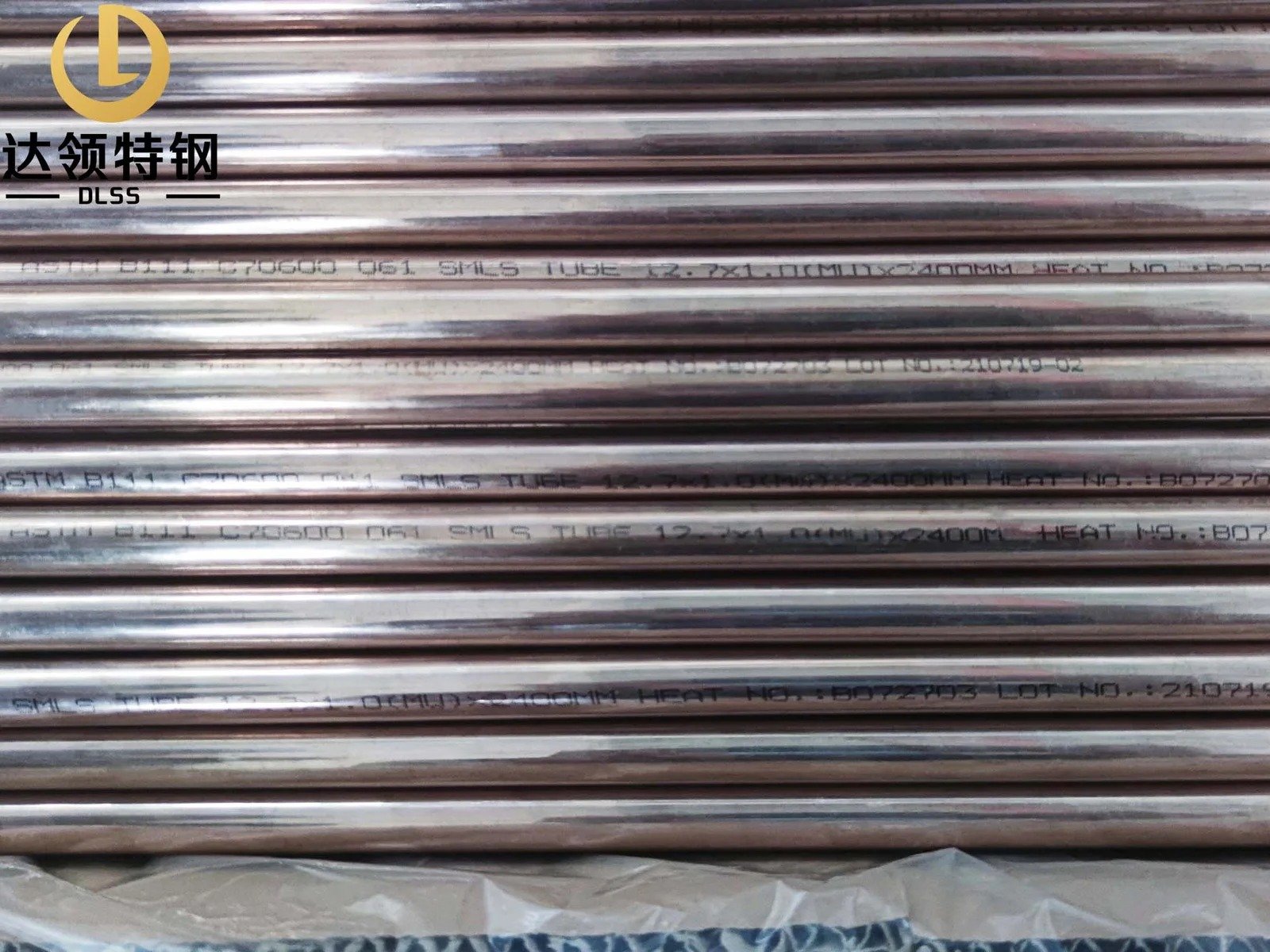

Type: Seamless Tube (SMLS)

-

Size: ∅25 mm OD × 1.0 mm min WT × 6000 mm Length

-

Testing: 100% HT + 100% ET + 100% UT

-

Corrosion Resistance: Good resistance in oxidizing and mildly corrosive environments

-

Application: Heat Exchangers, Boilers, Power Plants, Chemical Processing

Specifications

| Item | Details |

|---|---|

| Standard | ASME SA213 |

| Material | TP304 Stainless Steel (18Cr-8Ni) |

| Type | Seamless Tube |

| Size | 25×1.0(min)×6000 mm |

| Testing | 100% HT + 100% ET + 100% UT |

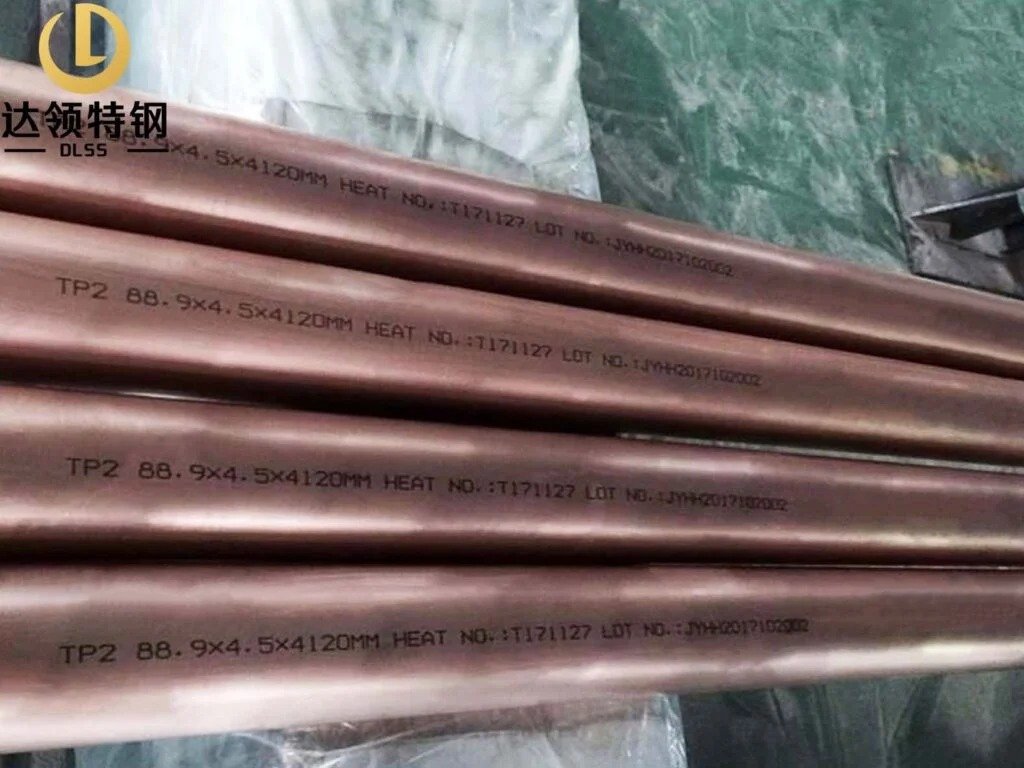

| Applications | Heat Exchangers, Boilers, Refinery Units, Condensers, Marine Systems |

Advantages of TP304

-

Corrosion Resistance – suitable for a wide range of media including water, steam, and mild chemicals.

-

Good Weldability & Formability – easy to fabricate and integrate into heat exchanger bundles.

-

Reliable Testing – ET + UT ensure detection of both surface and internal defects.

-

Heat Treatment Stability – prevents stress cracking and ensures durability.

-

Cost-Effective – compared with high-alloy steels, TP304 provides an economical solution.

Applications

-

Heat Exchangers & Condensers – widely used in power plants and chemical plants.

-

Boilers & Superheaters – reliable performance under temperature cycling.

-

Petrochemical Industry – refinery piping and processing units.

-

Marine Engineering – general seawater cooling applications (non-aggressive service).

-

Food & Beverage Industry – hygienic processing lines due to clean surface finish.

Quality Assurance

DLSS provides strict inspection and testing:

-

100% HT – ensures stable mechanical properties.

-

100% ET – detects surface cracks and pinholes.

-

100% UT – detects internal defects.

-

PMI & Dimensional Testing – verify grade and tolerances.

-

Third-Party Inspection – SGS, BV, TUV, LR available upon request.

FAQ

Q1: What’s the difference between TP304 and TP304L?

A1: TP304L has lower carbon, improving weldability and resistance to sensitization; TP304 is stronger at higher temperatures.

Q2: Why both ET and UT testing?

A2: ET (Eddy Current) detects surface flaws, while UT (Ultrasonic) detects subsurface/internal defects – providing full integrity assurance.

Q3: Can TP304 be used in seawater?

A3: TP304 is suitable for mild marine service, but for aggressive chloride conditions, duplex or TP316L is recommended.

Why Choose DLSS?

-

30+ years of manufacturing expertise in seamless stainless tubes.

-

Comprehensive testing (HT, ET, UT) ensures safe use in heat exchangers.

-

Global supply references with EPCs, refineries, and power plants.

-

Seaworthy packaging with PE caps, plastic wrap, and wooden cases.