Introduction

The ASME SA815 WPS32750 Stub End is a forged pipe fitting made from super duplex stainless steel (UNS S32750), designed for use with lap joint flanges in demanding applications. With a balanced austenitic-ferritic microstructure, S32750 offers exceptional strength (yield ≥550 MPa) and outstanding resistance to seawater and chloride-induced corrosion.

This stub end is DN100, SCH40S, seamless (SMLS), manufactured in Short Pattern Type B according to MSS-SP-43, suitable for high-strength and corrosion-critical systems in offshore, marine, chemical, and power plant applications.

Key Features

-

Material: Super Duplex Stainless Steel WPS32750 (UNS S32750)

-

Standard: ASME SA815 / MSS-SP-43

-

Type: Stub End – Short Pattern, Type B

-

Size: DN100 (4″ Nominal Bore)

-

Schedule: SCH40S (medium wall)

-

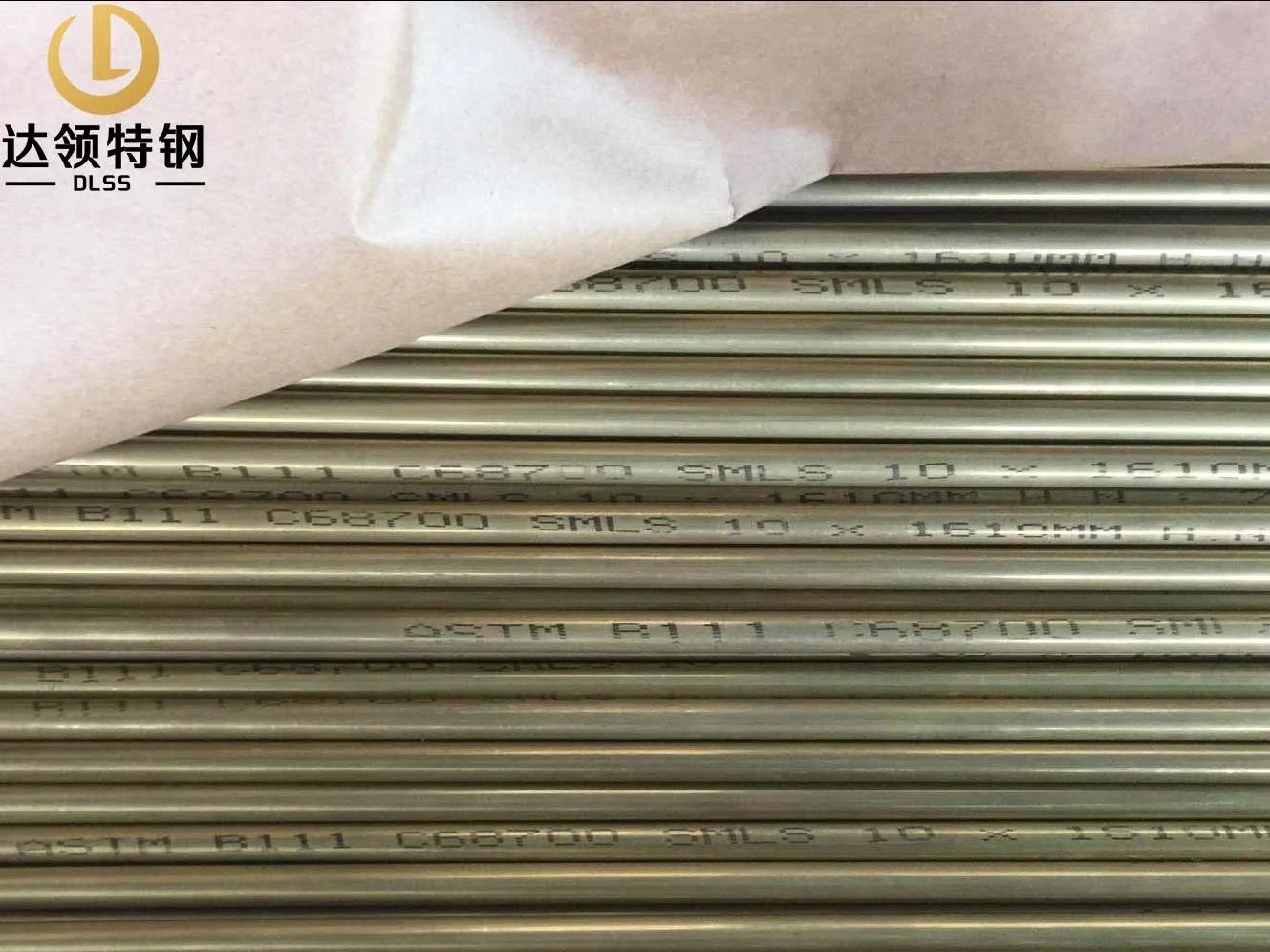

Manufacturing: Seamless (SMLS) for maximum integrity

-

Strength: Yield strength ≥550 MPa

-

Corrosion Resistance: Excellent against seawater, brine, acids, and chlorides

Specifications

| Item | Details |

|---|---|

| Standard | ASME SA815 / MSS-SP-43 |

| Material | Super Duplex Stainless Steel WPS32750 |

| Type | Stub End – Short Pattern, Type B |

| Size | DN100 (4″) |

| Schedule | SCH40S |

| Manufacturing | Seamless (SMLS) |

| Applications | Offshore, Marine, Oil & Gas, Desalination, Chemical & Power Plants |

Applications

-

Offshore & Marine Engineering – subsea piping, seawater cooling, desalination.

-

Oil & Gas Industry – risers, manifolds, and chemical injection lines.

-

Power Generation – boiler piping, condensers, heat exchangers.

-

Chemical Processing – acid piping, chloride-rich environments.

-

Water Treatment – brine discharge, desalination plants.

Advantages of Super Duplex S32750

-

High Strength – almost double that of standard stainless steel grades.

-

Superior Corrosion Resistance – PREN > 40, strong protection against pitting and crevice corrosion.

-

Chloride SCC Resistance – excellent for seawater and brine systems.

-

Extended Service Life – reduces downtime and maintenance costs.

-

Cost Efficiency – can replace higher-cost nickel alloys in many applications.

Why Choose DLSS?

-

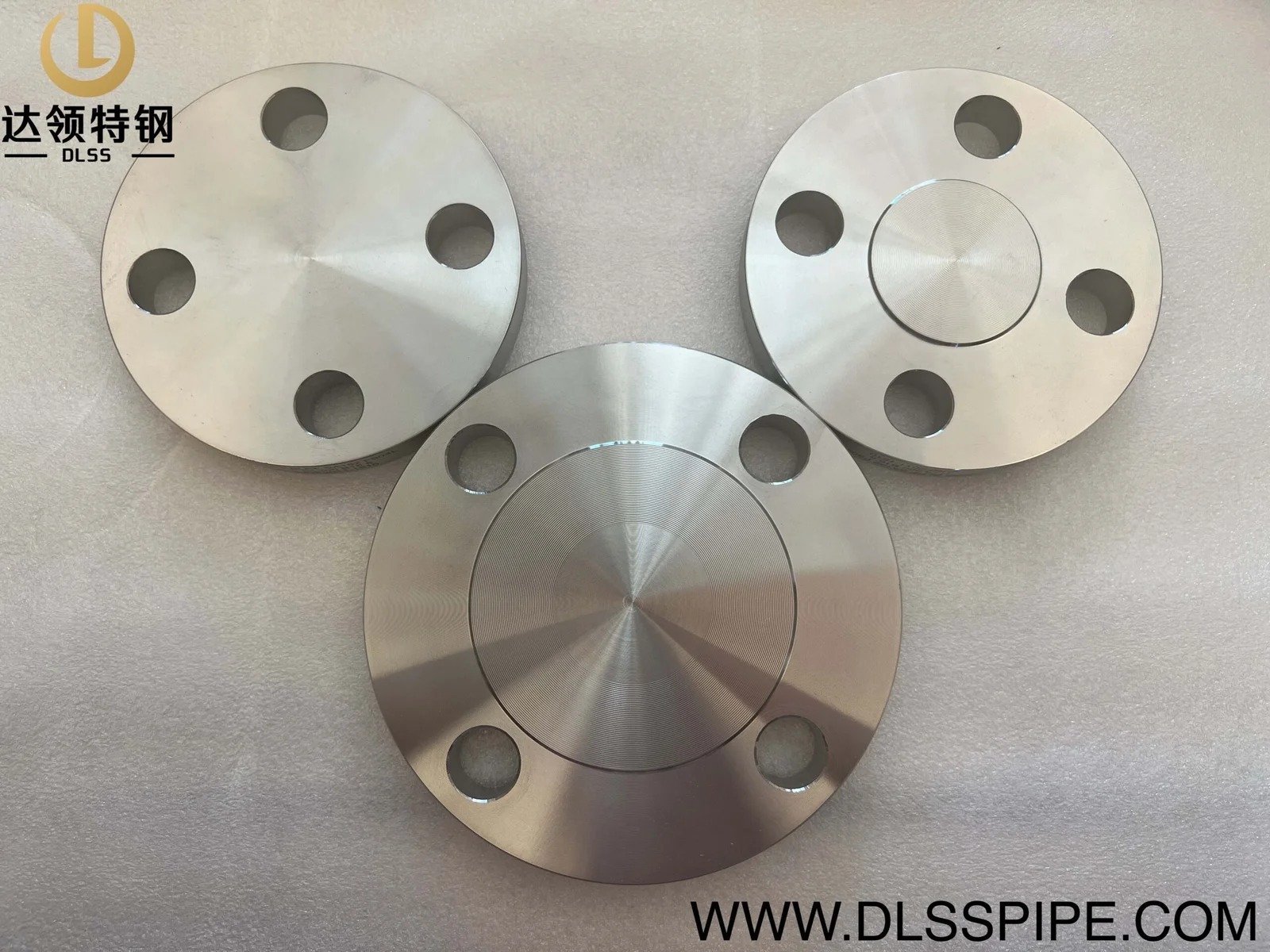

Full supply of super duplex fittings: elbows, tees, reducers, stub ends, flanges.

-

Strict Quality Control – PMI, Hydro, UT, ET, dimensional checks.

-

Third-Party Inspection – SGS, BV, TUV, LR certifications available.

-

Global References – supplied super duplex products to offshore, petrochemical, and power projects.

-

Export-Ready Packaging – PE caps, plastic wrapping, seaworthy wooden cases.