Product Description

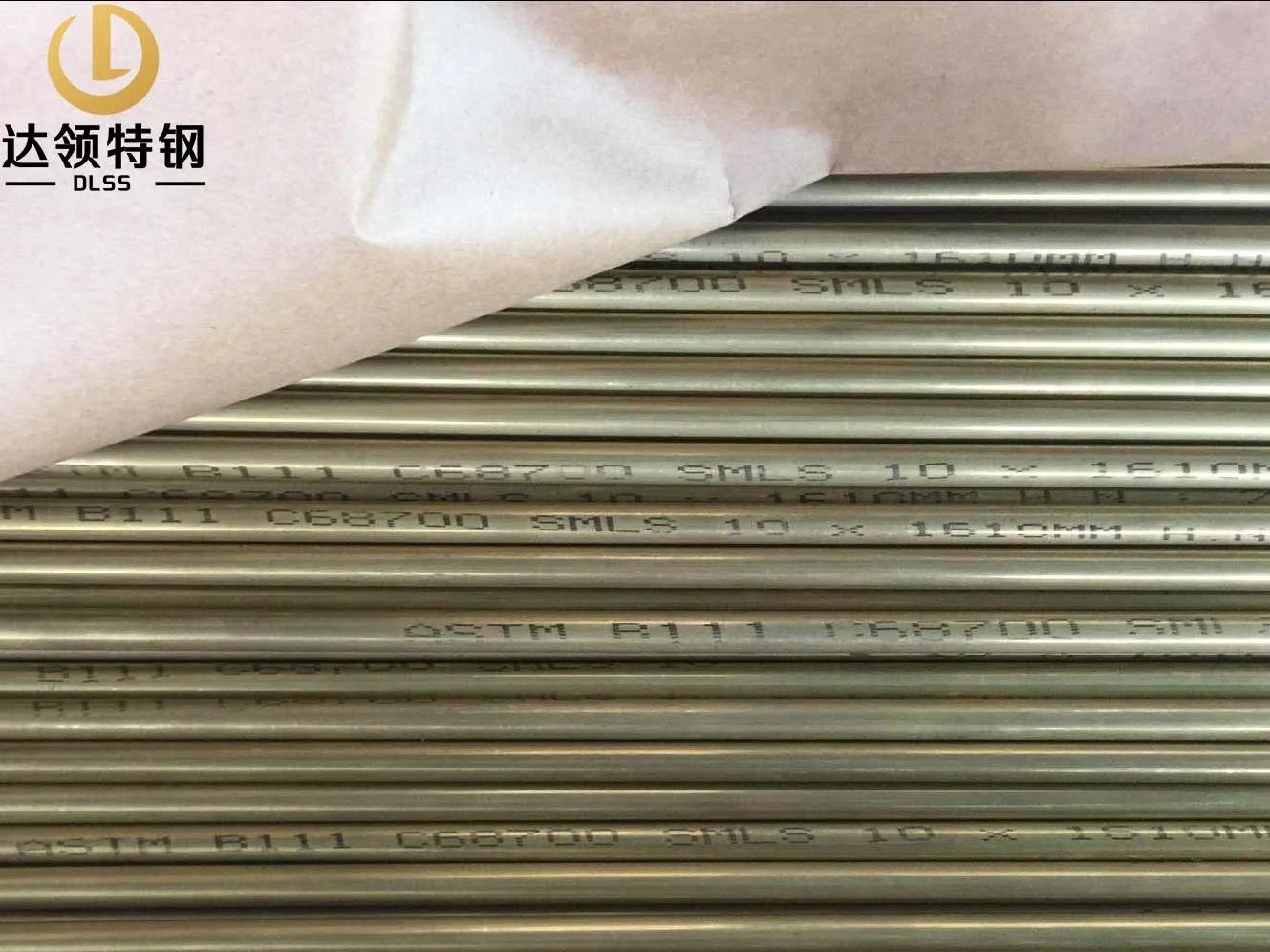

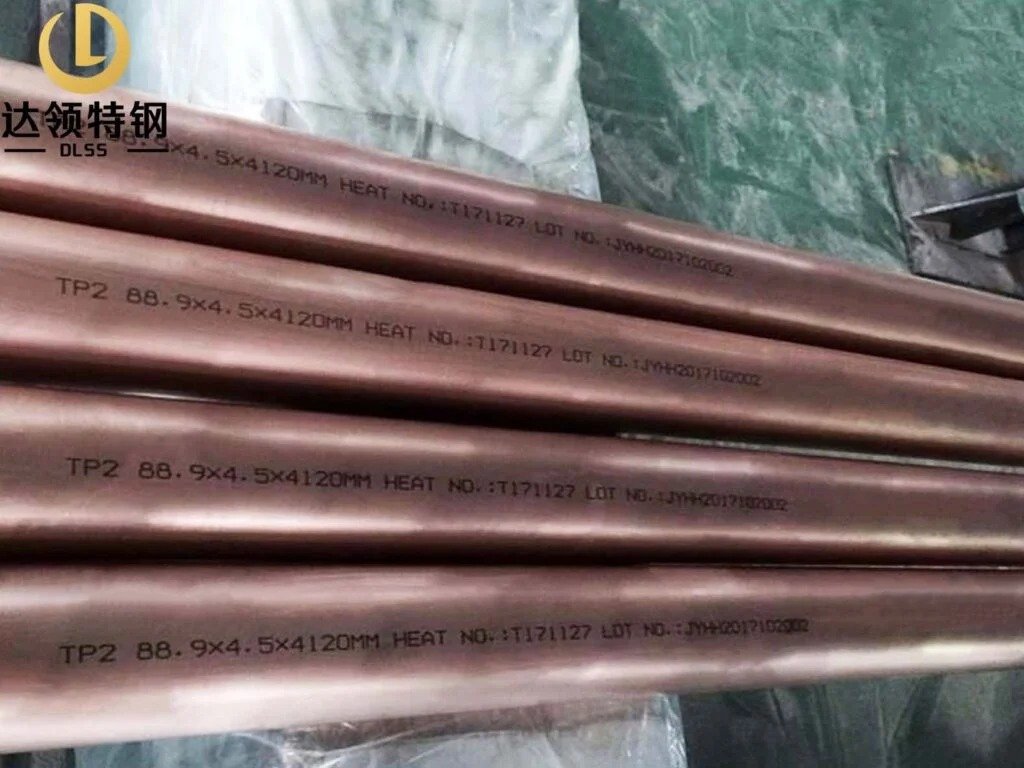

DLSS supplies ASME SB111 C70600 (O61) seamless tubes in size 16 mm OD × 1.0 mm wall thickness × 8600 mm length, specially designed for seawater equipment and cooling systems. Manufactured according to ASME SB111, these seamless copper-nickel tubes provide a proven solution for marine engineering, desalination, offshore oil & gas, and power plant condensers.

The material C70600 (CuNi 90/10) contains 90% copper and 10% nickel with controlled additions of iron and manganese, offering superior resistance to seawater corrosion, erosion, and biofouling. Condition O61 (annealed) ensures excellent ductility and formability, suitable for fabrication into U-bend or coiled configurations.

Each tube undergoes 100% Hydrostatic Test (HT) to guarantee strength and leak-free performance in demanding marine service.

Specifications

| Item | Details |

|---|---|

| Standard | ASME SB111 |

| Material | C70600 Copper-Nickel (90/10) |

| Condition | O61 (Annealed) |

| Type | Seamless Tube |

| Size | 16 mm OD × 1.0 mm WT × 8600 mm Length |

| Testing | 100% Hydrostatic Test (HT) |

| Corrosion Resistance | Excellent in seawater and chloride-rich environments |

| Applications | Seawater equipment, condensers, desalination, offshore & marine piping |

Key Features

-

Seamless Construction – Ensures high strength, pressure resistance, and smooth internal bore.

-

Outstanding Corrosion Resistance – Proven performance in seawater, brine, and marine environments.

-

O61 Annealed Condition – Provides ductility and ease of fabrication into U-tubes and coils.

-

100% Hydrostatic Testing – Leak-proof and safe for high-pressure seawater applications.

-

Trusted Material – CuNi 90/10 alloy widely used in shipbuilding, desalination, and offshore industries.

Applications

-

Seawater Cooling Systems – in power plants and marine vessels.

-

Desalination Plants – resistant to high salinity and brine solutions.

-

Heat Exchangers & Condensers – handling seawater and brackish water.

-

Offshore Oil & Gas – subsea piping and platform cooling systems.

-

Marine Engineering – shipbuilding and engine cooling applications.

Why Choose DLSS?

-

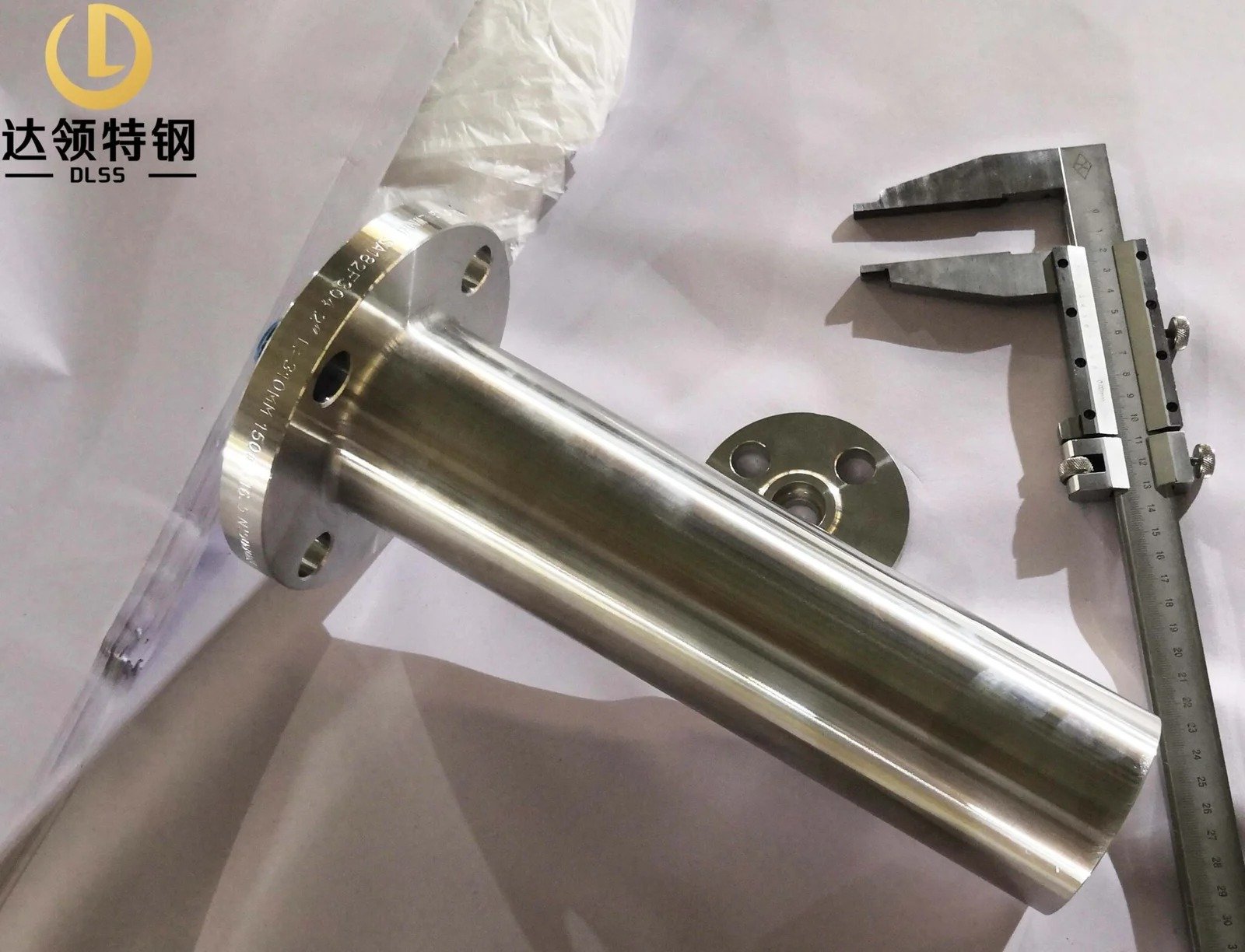

Full Copper-Nickel Piping Package – supply of tubes, pipes, flanges, and fittings in C70600.

-

Certified Quality – Mill Test Certificate (EN 10204/3.1) provided, third-party inspection available.

-

Strict Testing – 100% Hydrostatic, with optional Eddy Current and Ultrasonic testing.

-

Export-Ready Packing – tubes supplied with end caps, plastic wrapping, and ISPM-15 wooden cases.

-

Global Supply Experience – trusted by power plants, shipyards, and EPC contractors worldwide.

-

Frequently Asked Questions (FAQ)

Q1: Why is C70600 preferred for seawater equipment?

A1: Because CuNi 90/10 has excellent resistance to seawater corrosion, erosion, and biofouling, ensuring long service life.

Q2: What does O61 mean in tube supply?

A2: O61 is the annealed condition, which improves ductility and makes tubes easier to fabricate into bends or coils.

Q3: Can DLSS supply longer lengths than 8600 mm?

A3: Yes, customized lengths are available according to project requirements.

Q4: What certifications are included?

A4: MTC (EN 10204/3.1) is standard, with optional SGS, BV, TUV third-party inspection.