Introduction

ASME SB163 Incoloy 800HT Seamless Pipe (UNS N08811) is a high-performance nickel-iron-chromium alloy pipe designed for high-temperature strength, oxidation resistance, and long-term structural stability. Compared to Incoloy 800 and 800H, the 800HT grade has improved creep rupture properties, making it ideal for boilers, superheaters, reformer tubes, and heat exchangers.

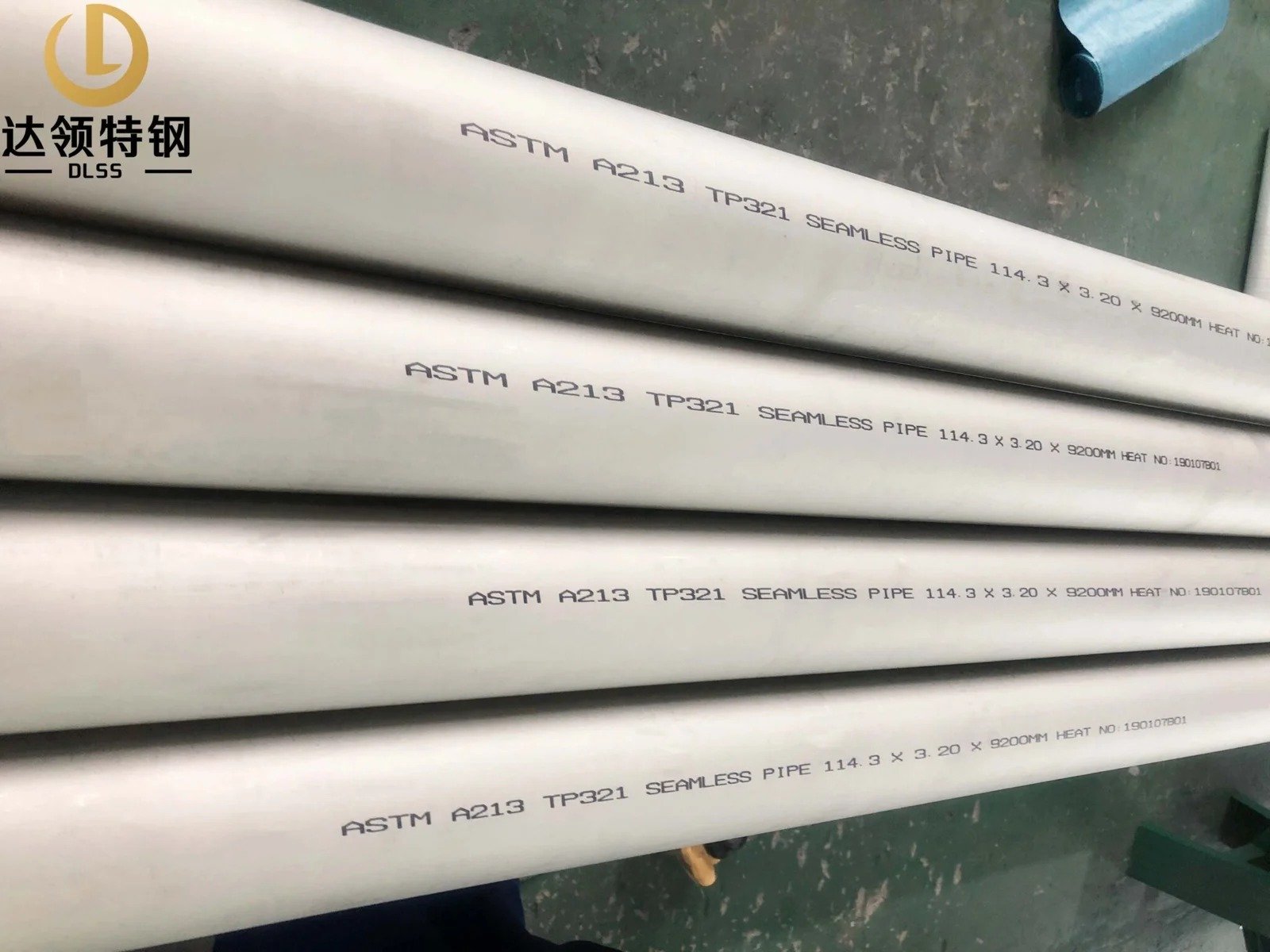

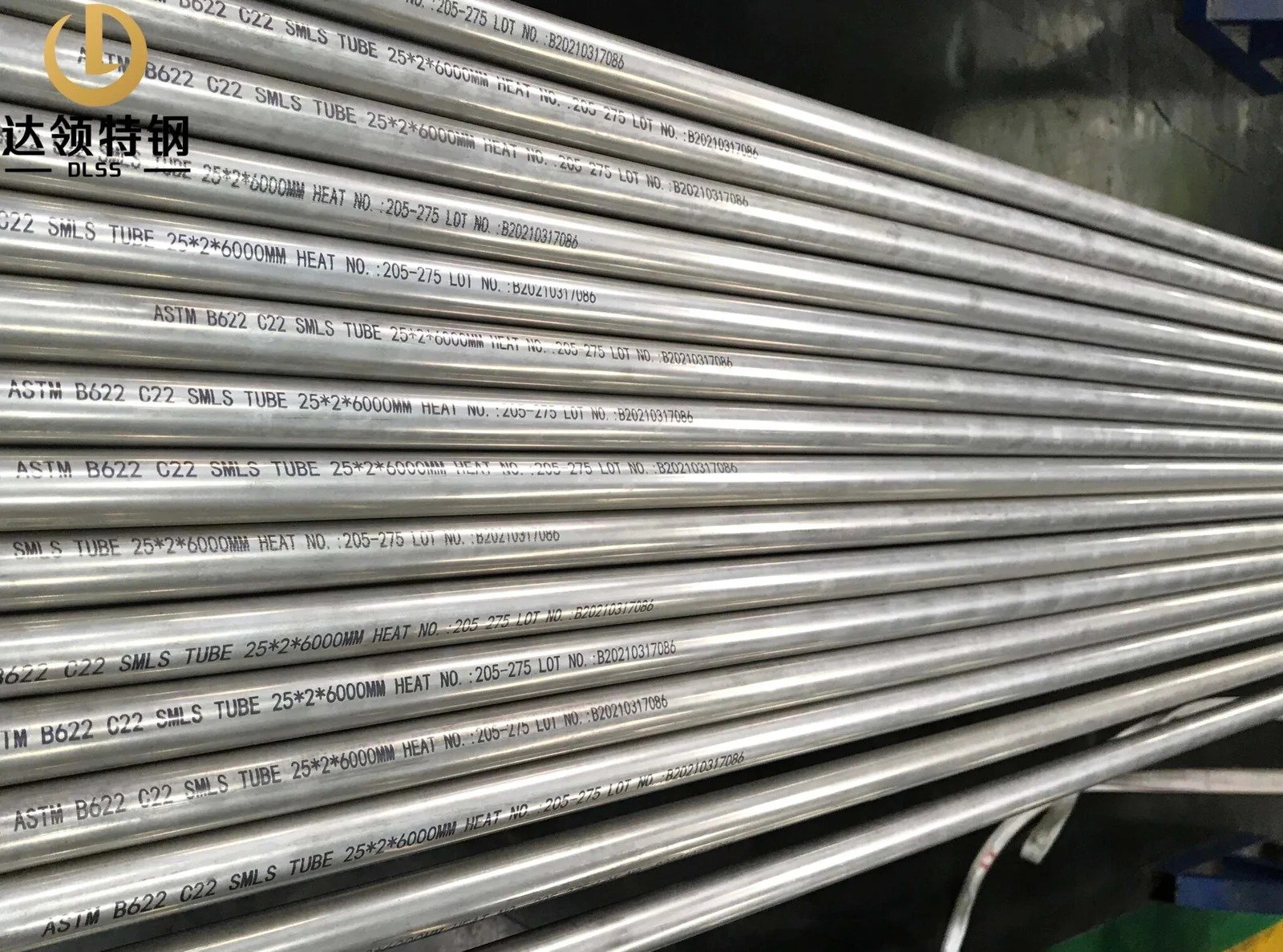

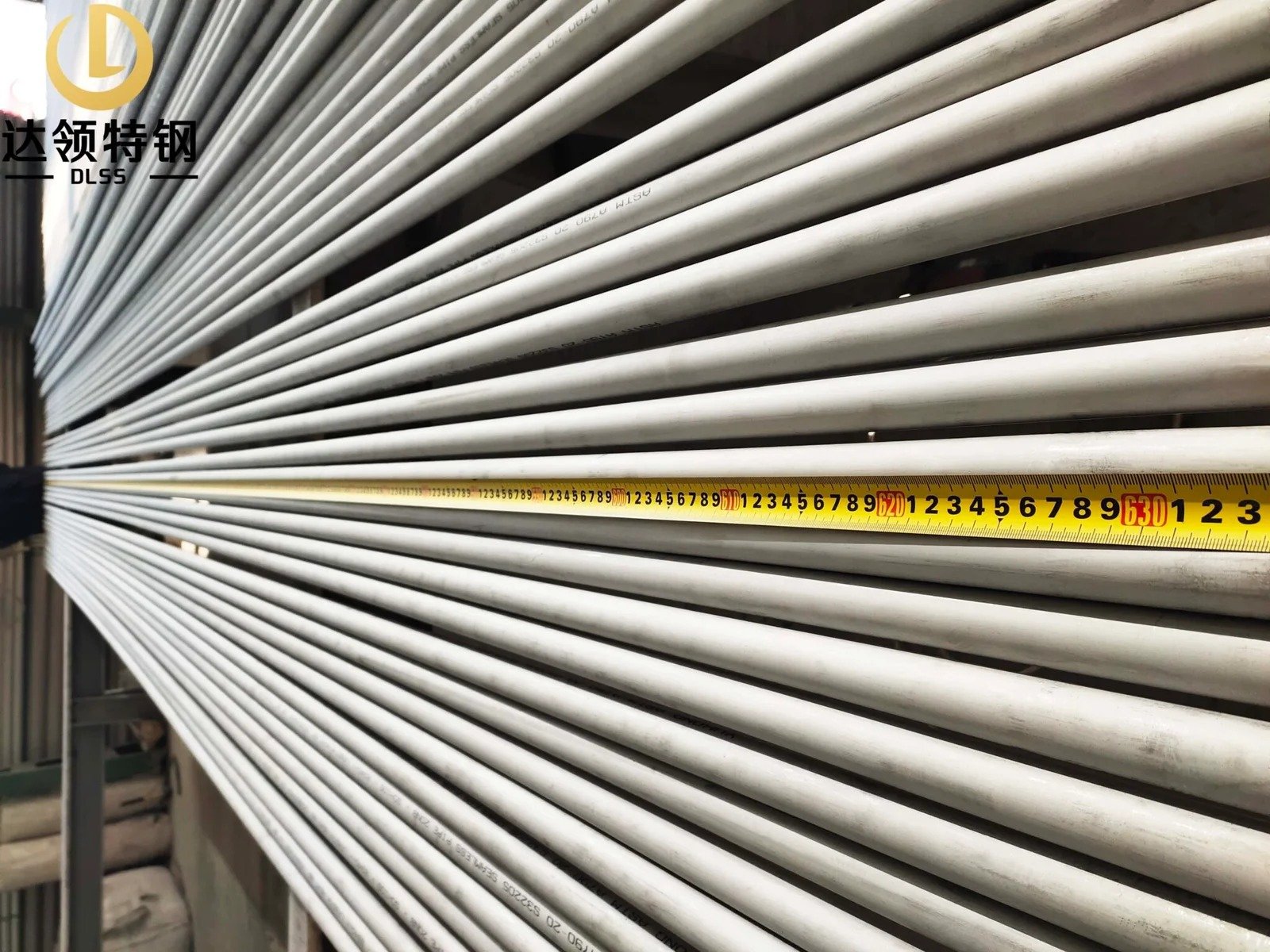

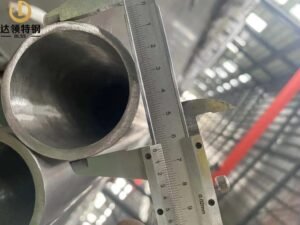

DLSS supplies 64 mm OD × 4.5 mm WT × 4000 mm length seamless pipes, manufactured to ASME SB163, with a bright surface finish for smoothness and corrosion resistance. These pipes are widely used in power generation, petrochemical furnaces, and high-temperature process piping.

Key Properties of Incoloy 800HT Seamless Pipe

-

High Temperature Resistance – performs reliably up to ~1100°C.

-

Improved Creep Strength – designed for long-term service under constant stress.

-

Oxidation & Carburization Resistance – protects against scale formation at elevated temperatures.

-

Enhanced Structural Stability – controlled carbon, aluminum, and titanium ensure excellent creep rupture life.

-

Versatile Applications – ideal for industrial furnaces, petrochemical units, and boiler systems.

Specifications

| Item | Details |

|---|---|

| Standard | ASME SB163 |

| Material | Incoloy 800HT (UNS N08811) |

| Type | Seamless Pipe |

| Size | 64 mm OD × 4.5 mm WT × 4000 mm Length |

| Surface Finish | Bright Surface |

| Condition | Solution Annealed |

| Applications | Boilers, Heat Exchangers, Petrochemical Furnaces, Superheaters, Reformers |

Applications

-

Boilers & Superheaters – withstands high-pressure steam and cyclic heating.

-

Heat Exchangers – maintains stability under repeated thermal stress.

-

Petrochemical Processing – reformer tubes, cracking units, and furnace pipes.

-

Power Generation – piping in turbine and high-pressure systems.

-

Industrial Heating – kilns, thermal oxidizers, chemical reactors.

Incoloy 800H vs 800HT vs 825 – Comparison

| Item / Alloy | Incoloy 800H (UNS N08810) | Incoloy 800HT (UNS N08811) | Incoloy 825 (UNS N08825) |

|---|---|---|---|

| Standard | ASME SB407 / SB163 | ASME SB407 / SB163 | ASME SB423 / SB705 |

| Composition | Ni 30–35%, Cr 19–23%, Fe balance, Ti/Al control | Ni 30–35%, Cr 19–23%, Fe balance, tighter Ti/Al | Ni 38–46%, Cr 19–23%, Mo 2.5–3.5%, Cu 1.5–3% |

| Main Strength | High temperature creep strength | Superior creep rupture strength, long-term use | Excellent corrosion resistance in acids |

| Temperature Range | Up to ~1000°C | Up to ~1100°C | Up to ~540°C |

| Oxidation Resistance | Good | Excellent | Good |

| Corrosion Resistance | Moderate (oxidizing environments) | Moderate, focus on high-temp durability | Excellent in sulfuric, phosphoric, nitric acids |

| Typical Applications | Heaters, reformer tubes, furnace components | Boilers, heat exchangers, petrochemical heaters | Chemical processing, desalination, acid piping |

| Summary | Best for general high-temp service | Best for high-temp, long-term creep strength | Best for acid & seawater corrosion resistance |

Professional Summary

-

Incoloy 800H – strong at high temperature, but limited creep life compared to 800HT.

-

Incoloy 800HT – the best option for sustained high-temperature service such as boilers, reformers, and superheaters.

-

Incoloy 825 – optimized for corrosion resistance in sulfuric, phosphoric, and seawater environments, rather than extreme heat.

For boilers and high-pressure heat exchangers, choose 800HT.

For furnace components, 800H may be sufficient.

For acid and marine service, use 825.

Why Choose DLSS?

-

Supply of complete nickel alloy piping solutions: Incoloy 800/800H/800HT, 825, Inconel 600/625, Hastelloy, Monel, Alloy 20.

-

Strict Testing – 100% Eddy Current, UT, Hydro, and PMI inspection.

-

Third-Party Certification – SGS, BV, TUV approved for EPC projects.

-

Seaworthy Packaging – capped ends, plastic wrapping, ISPM-15 wooden cases.

-

Global Experience – delivered to power plants, refineries, and petrochemical projects worldwide.