Introduction

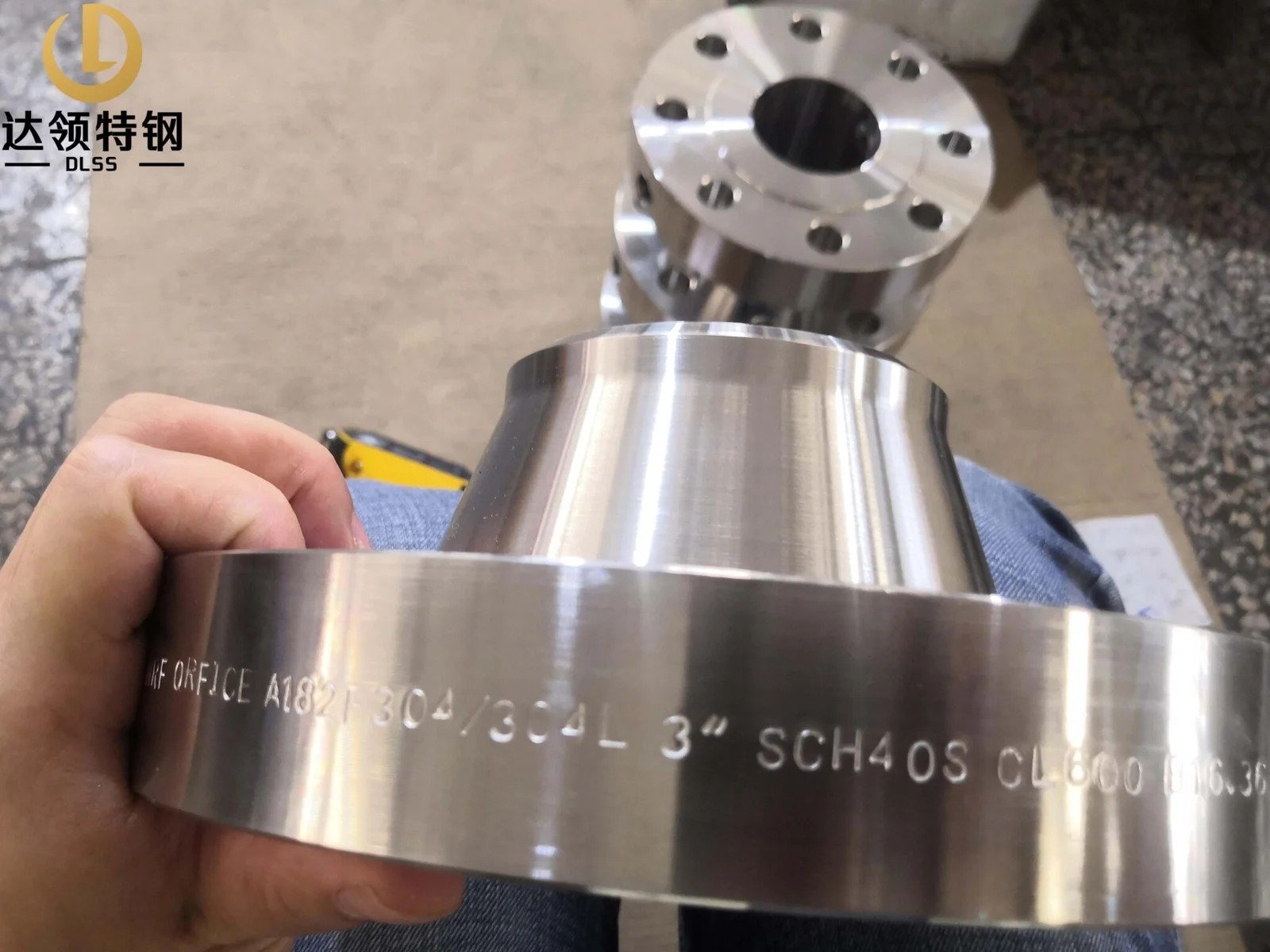

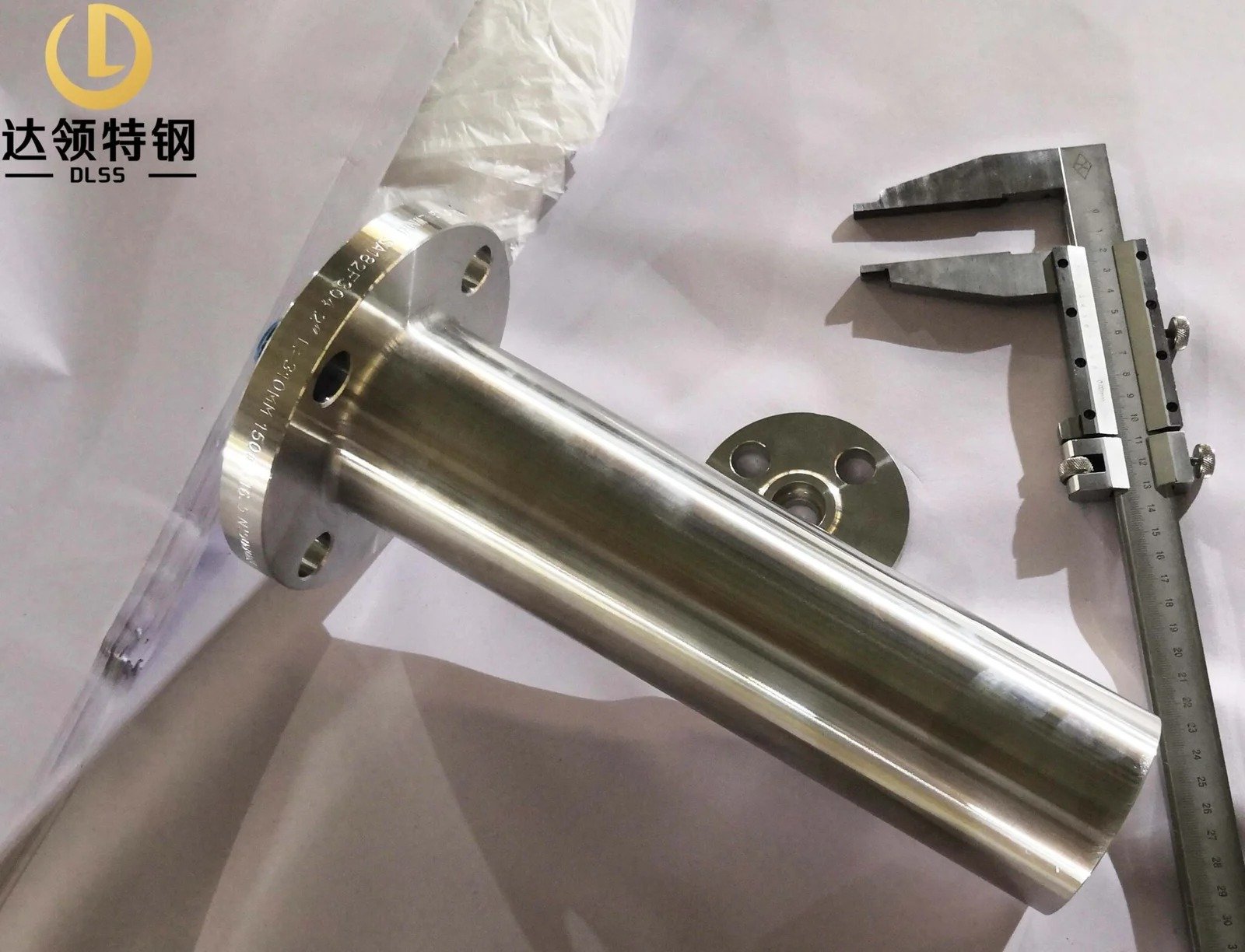

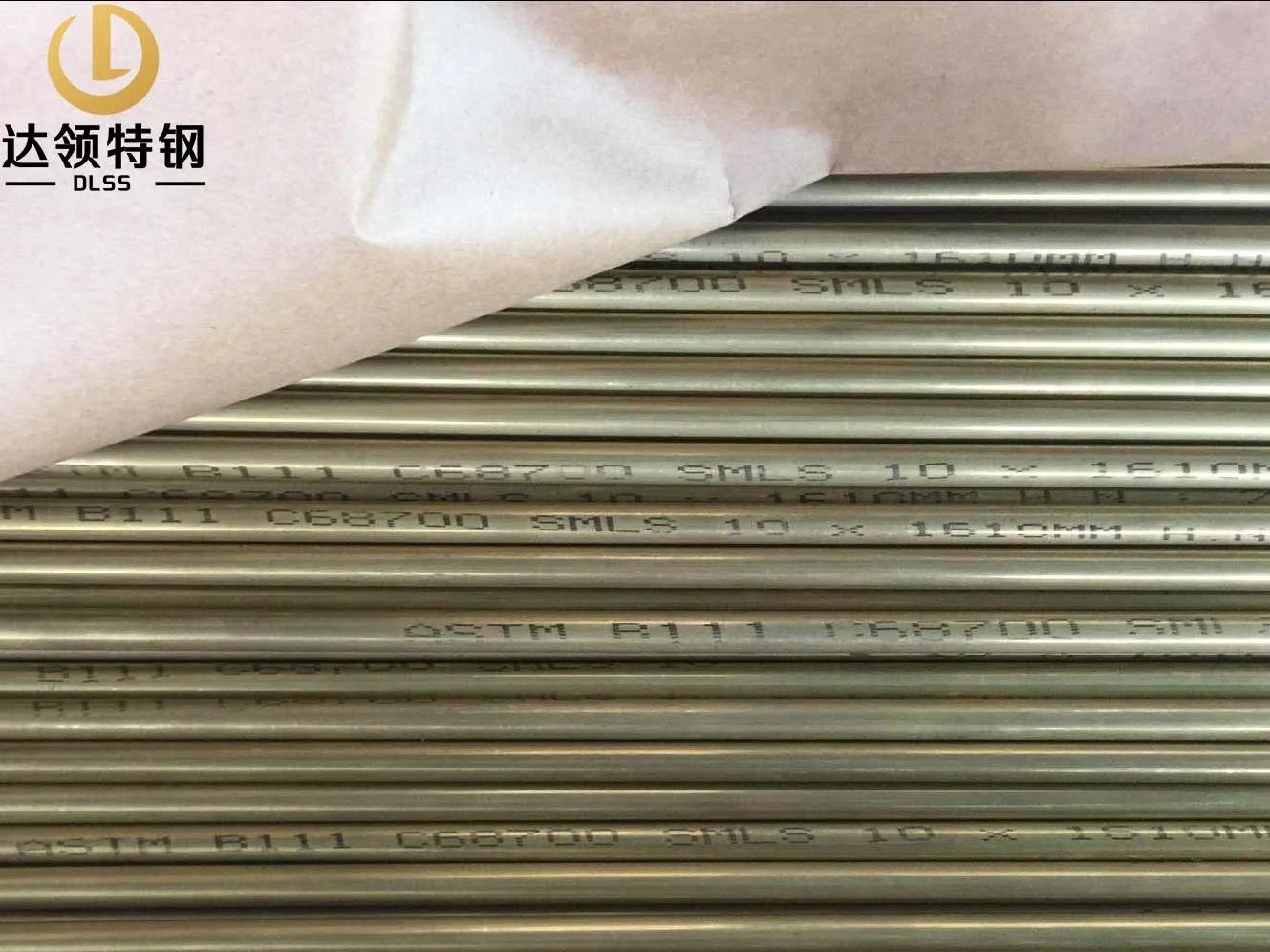

The ASTM A182 F321 Forged Flange Ring is a high-temperature stainless steel forging designed for heat exchanger plants and industrial piping systems. Manufactured from titanium-stabilized stainless steel (TP321), this flange ring provides excellent resistance to intergranular corrosion and superior strength at elevated temperatures, making it a reliable choice for demanding thermal and mechanical conditions.

DLSS supplies forged flange rings in ASTM A182 F321, precisely machined to customer specifications, ensuring perfect fit and long-term durability in heat exchangers, boilers, and refinery systems.

Key Features

-

Material: Stainless Steel ASTM A182 F321 (UNS S32100)

-

Type: Forged Flange Ring

-

Standard: ASTM A182 / ASME B16.5 (dimensions upon request)

-

Stabilization: Titanium stabilized to prevent carbide precipitation

-

Temperature Resistance: Performs well up to 870°C (1600°F)

-

Corrosion Resistance: Excellent against oxidation, scaling, and intergranular corrosion

-

Applications: Heat exchangers, boilers, chemical plants, oil & gas, and power stations

Specifications

| Item | Details |

|---|---|

| Standard | ASTM A182 / ASME B16.5 |

| Material | Stainless Steel F321 (Ti-stabilized austenitic SS) |

| Type | Forged Flange Ring |

| Application | Heat Exchanger Plant, Boilers, Petrochemical, Power Generation |

| Surface | Machined, pickled, or coated upon request |

| Sizes | Customized (DN, Class, thickness) |

Advantages of ASTM A182 F321

-

Titanium Stabilization – minimizes risk of intergranular corrosion after welding.

-

High-Temperature Strength – retains mechanical properties up to 870°C.

-

Durability – forged structure enhances toughness and reliability.

-

Corrosion Resistance – resists scaling, oxidation, and acids in refinery & chemical service.

-

Versatility – widely used in heat exchangers, pressure vessels, and industrial piping.

Applications

-

Heat Exchanger Plants – tube sheets, flange rings, headers.

-

Boiler Systems – high-temperature steam and water piping.

-

Petrochemical Industry – refinery piping, catalytic equipment.

-

Power Generation – turbine piping, condenser systems.

-

Industrial Piping Systems – where high heat and corrosion resistance are critical.

Quality Assurance

DLSS ensures strict compliance with international standards:

-

Forging & Machining Precision – customized dimensions.

-

100% PMI Testing – ensures correct grade F321.

-

NDT (UT, ET, RT) – verifies structural soundness.

-

Heat Treatment Records – traceable process control.

-

Third-Party Inspection – SGS, BV, TUV available upon request.