Introduction

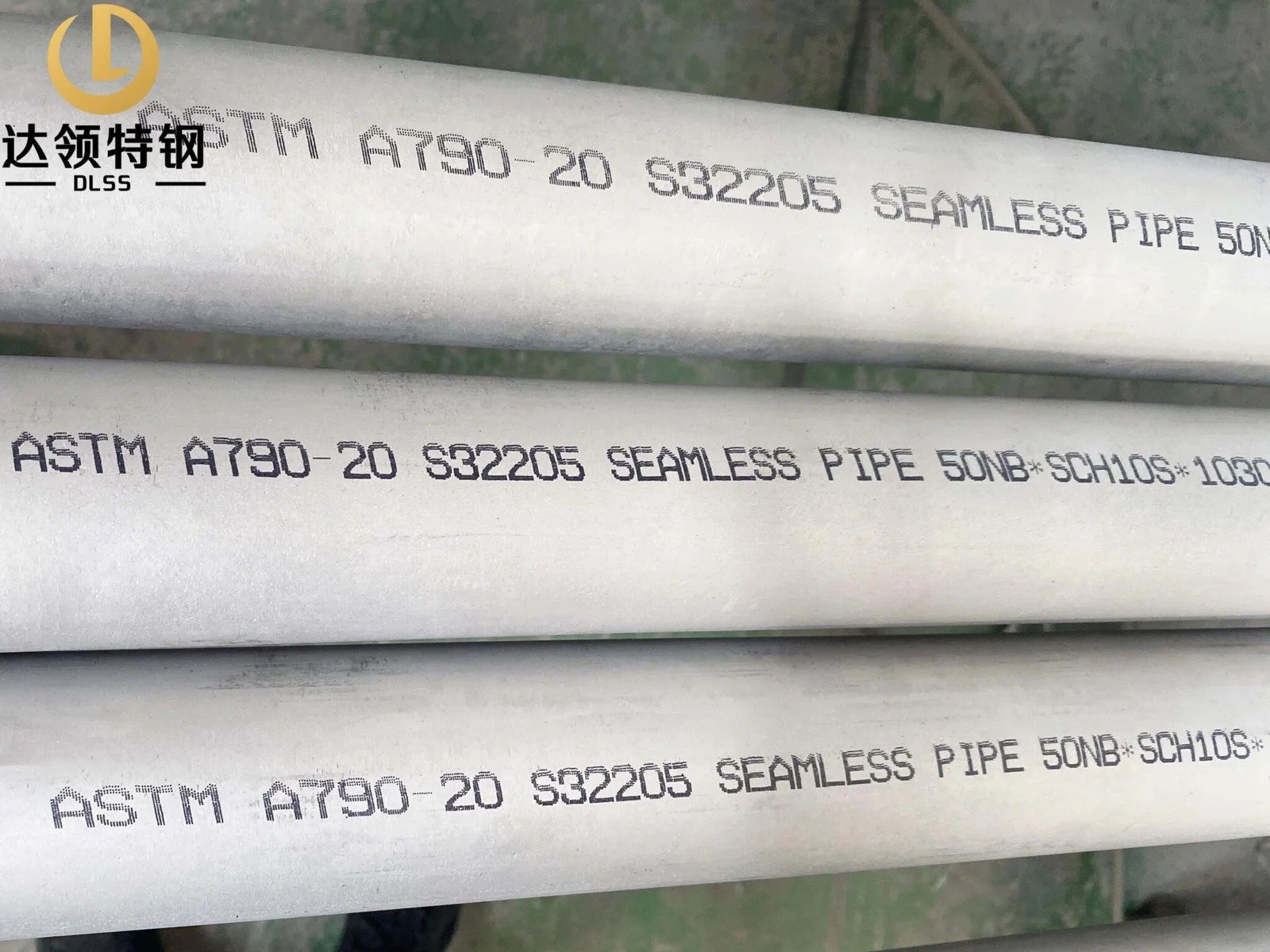

The ASTM A182 S32205 F60 WNRF Forged Flanges are high-performance duplex stainless steel flanges designed for use in oil & gas, petrochemical, power, and marine applications. With a balanced austenitic-ferritic microstructure, duplex grade F60 (UNS S32205) offers twice the strength of conventional austenitic stainless steels and superior resistance to chloride-induced stress corrosion cracking, pitting, and crevice corrosion.

The Weld Neck Raised Face (WNRF) design provides excellent strength, fatigue resistance, and leak-proof connections, making it ideal for high-pressure and high-temperature piping systems.

Key Features

-

Material: Duplex Stainless Steel F60 (UNS S32205, 1.4462)

-

Standard: ASTM A182 / ASME B16.5

-

Type: Weld Neck Raised Face (WNRF) Forged Flange

-

Class: Available in 150#, 300#, 600#, 900#, up to 2500#

-

Size Range: 1/2″ to 48″ (DN15 – DN1200)

-

Strength: Yield ≥450 MPa, Tensile ≥620 MPa

-

Corrosion Resistance: Superior resistance in seawater, brine, and aggressive chemicals

Specifications

| Item | Details |

|---|---|

| Standard | ASTM A182 / ASME B16.5 |

| Material | Duplex Stainless Steel S32205 F60 (UNS S32205, 1.4462) |

| Type | Weld Neck Raised Face (WNRF) Forged Flange |

| Pressure Class | 150# – 2500# |

| Size | 1/2″ – 48″ |

| Applications | Offshore, Oil & Gas, Petrochemical, Power Generation, Marine Systems |

Advantages of S32205 F60

-

High Strength – nearly double that of 304/316 stainless steels.

-

Excellent Corrosion Resistance – PREN > 34 ensures superior resistance to pitting and crevice corrosion.

-

Chloride SCC Resistance – ideal for marine and subsea service.

-

Weldability – suitable for complex piping systems with reliable performance.

-

Cost-Effective Alternative – replaces higher-cost nickel alloys in many applications.

Applications

-

Oil & Gas Industry – subsea pipelines, risers, and manifolds.

-

Marine & Offshore – seawater cooling, desalination plants.

-

Petrochemical Plants – process piping for chlorides and acids.

-

Power Generation – high-pressure boiler and heat exchanger piping.

-

Desalination – intake and brine discharge systems.

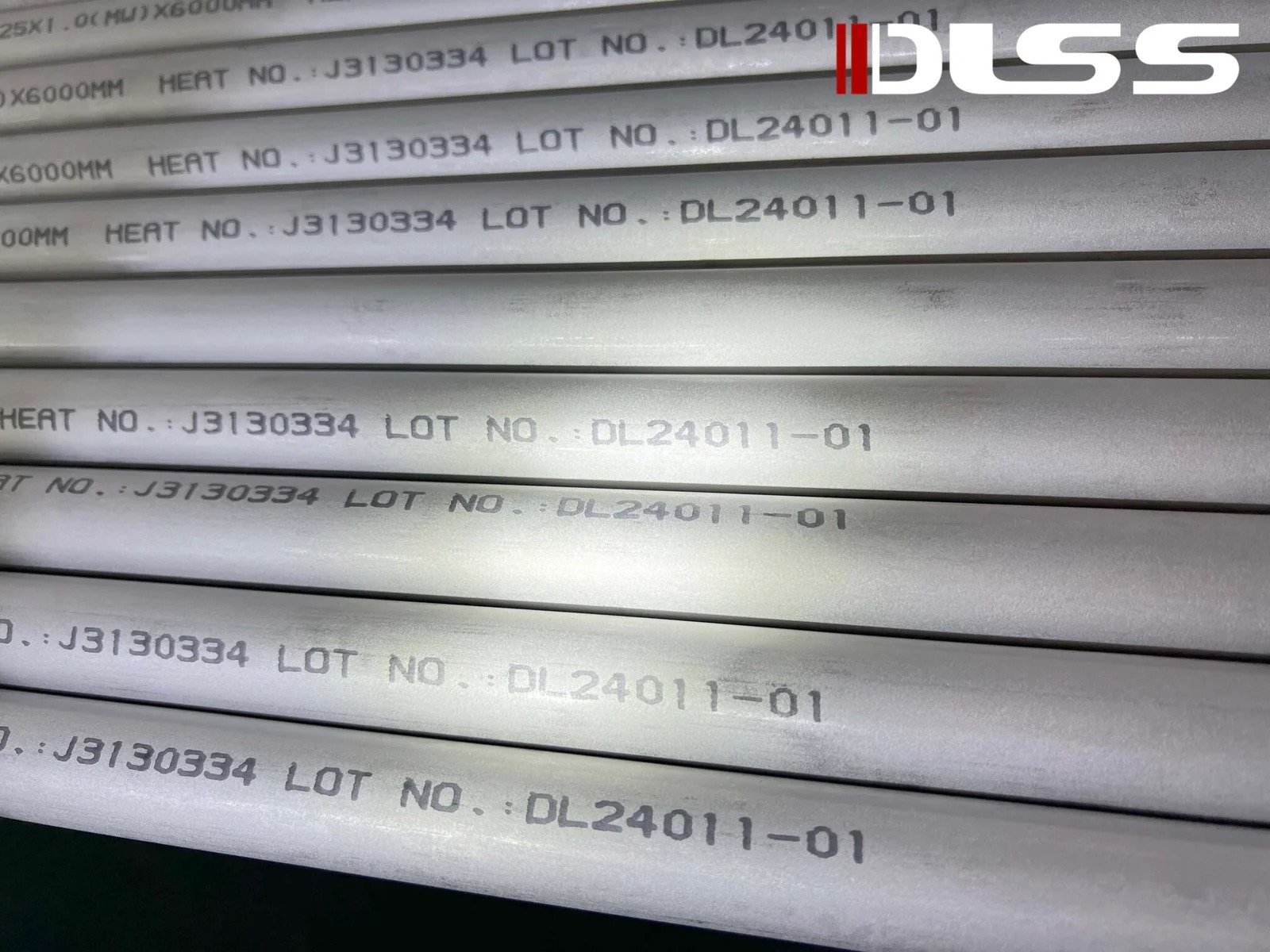

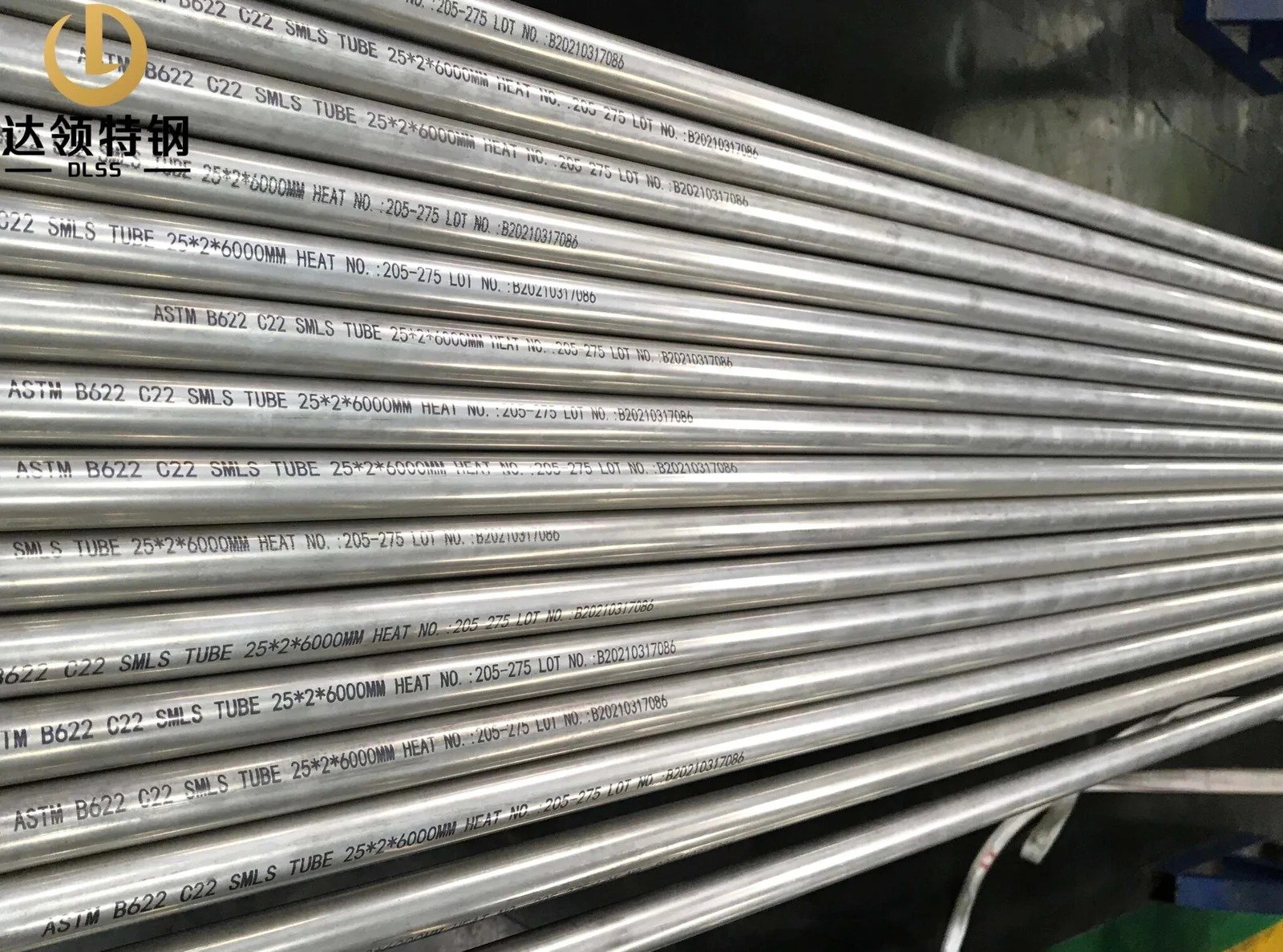

Quality Assurance

DLSS ensures strict compliance with international standards:

-

Forged & Heat Treated for optimum mechanical properties.

-

PMI Testing for chemical composition verification.

-

NDT (UT, ET, RT) to ensure defect-free integrity.

-

Dimensional & Pressure Testing as per ASME standards.

-

Third-Party Inspection (SGS, BV, TUV, LR) available upon request.

FAQ

Q1: Why choose duplex F60 flanges over 316L?

A1: Duplex F60 provides higher strength and much better chloride corrosion resistance, making it ideal for offshore and chemical applications.

Q2: What is WNRF?

A2: Weld Neck Raised Face flange design provides strong weld connections and enhanced gasket sealing for high-pressure service.

Q3: Can DLSS supply customized flanges?

A3: Yes, DLSS provides tailored dimensions, classes, and surface finishes upon customer request.

Why Choose DLSS?

-

30+ years of experience in stainless steel flanges and fittings.

-

Extensive global references in offshore, oil & gas, power, and chemical projects.

-

Comprehensive QC & certification ensures reliability.

-

Seaworthy packaging with PE caps, anti-rust coating, and wooden cases.