Introduction

The ASTM A213 TP304 Seamless Bright Annealed (BA) Tube is a high-quality stainless steel tube widely used in oil refineries, petrochemical plants, and power industries. With its 18/8 austenitic composition (18% Cr, 8% Ni), TP304 provides reliable corrosion resistance, excellent formability, and stable performance in high-temperature service.

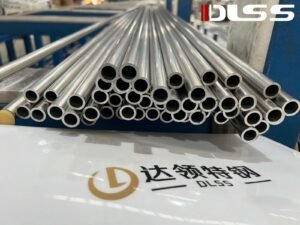

DLSS supplied ∅19×2.0(min)×12000mm seamless tubes, processed with Bright Annealed surface for a smooth, oxide-free finish. Every tube is fully tested with 100% Heat Treatment (HT), 100% Eddy Current Testing (ET), and 100% Ultrasonic Testing (UT) to guarantee both surface and internal integrity, making them ideal for oil refinery heat exchangers and process units.

Key Features

-

Material: Stainless Steel TP304 (UNS S30400 / 1.4301)

-

Standard: ASTM A213

-

Type: Seamless Bright Annealed Tube

-

Size: ∅19 mm OD × 2.0 mm min WT × 12000 mm Length

-

Surface: Bright Annealed (BA), smooth and oxide-free

-

Testing: 100% HT + 100% ET + 100% UT

-

Application: Oil refineries, chemical processing, boilers, condensers, and heat exchangers

Specifications

| Item | Details |

|---|---|

| Standard | ASTM A213 |

| Material | TP304 Stainless Steel (18Cr–8Ni) |

| Type | Seamless Bright Annealed Tube |

| Size | ∅19×2.0(min)×12000mm |

| Testing | 100% HT + 100% ET + 100% UT |

| Applications | Oil Refineries, Heat Exchangers, Boilers, Condensers, Power Plants |

Advantages of TP304 BA Tubes

-

Bright Annealed Finish – ultra-clean, smooth surface reduces scaling and fouling.

-

Comprehensive Testing – 100% HT for stability, ET for surface defects, UT for internal flaws.

-

Excellent Corrosion Resistance – reliable in refinery and chemical process media.

-

Long-Length Manufacturing (12m) – reduces weld joints in heat exchanger assembly.

-

Versatile Applications – suitable for petroleum, chemical, food, and marine industries.

Applications

-

Oil Refinery Heat Exchangers – process cooling and heating circuits.

-

Petrochemical Plants – corrosive fluid transfer.

-

Boilers & Condensers – stable under cyclic thermal stress.

-

Power Generation Systems – steam handling and high-temperature service.

-

General Process Piping – clean and corrosion-resistant tubing for industrial use.

Quality Assurance

DLSS ensures top-level quality with:

-

PMI Testing – confirms correct TP304 grade.

-

Dimensional Inspection – precise tolerance control for exchanger fit-up.

-

NDT (ET + UT) – ensures surface and internal defect-free tubes.

-

Third-Party Inspection – SGS, BV, TUV, LR available on request.

-

Seaworthy Packaging – PE end caps, plastic wrap, and wooden cases.

FAQ

Q1: Why choose Bright Annealed (BA) tubes for oil refineries?

A1: BA tubes provide smooth, oxide-free surfaces, ensuring cleaner fluid flow and reduced contamination.

Q2: Why both Eddy Current and Ultrasonic Testing?

A2: ET detects surface flaws, while UT identifies internal defects, ensuring total reliability.

Q3: Can DLSS supply extra-long tubes like 12 meters?

A3: Yes, DLSS offers up to 12m seamless tubes, reducing welds in large heat exchanger bundles.

Why Choose DLSS?

-

30+ years of tube manufacturing expertise.

-

Specialized in refinery and heat exchanger applications.

-

Comprehensive QC – HT, ET, UT, PMI, and dimensional checks.

-

Trusted supplier for EPC projects and oil majors worldwide.