Introduction

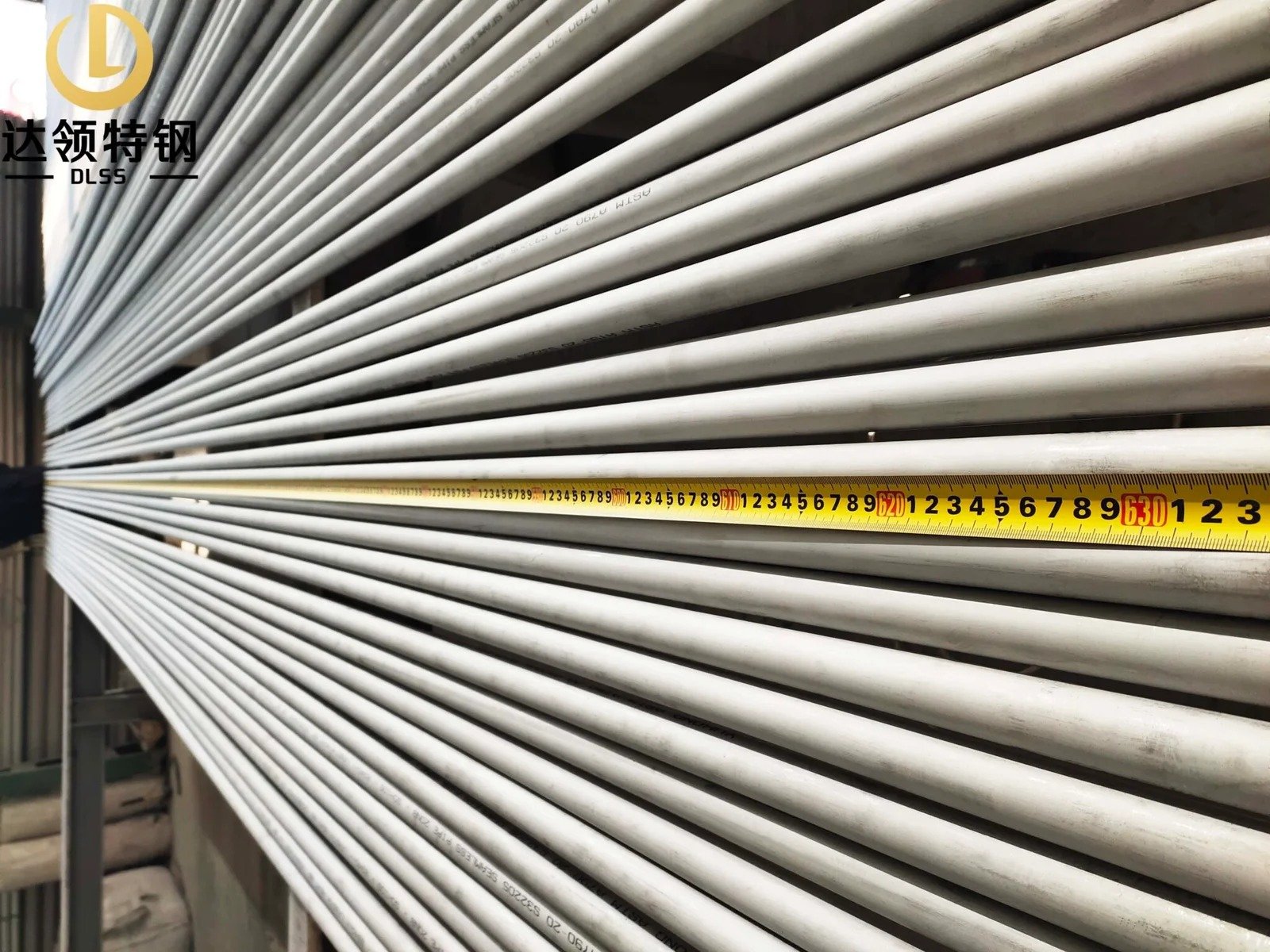

The ASTM A213/ASME SA213 TP321 (1.4541) Seamless Tube is a titanium-stabilized austenitic stainless steel tube widely used in heat exchanger applications. With its ability to resist intergranular corrosion and provide superior strength at elevated temperatures, TP321 is an excellent choice for thermal equipment, boilers, and petrochemical systems.

DLSS supplied 18×1.0MW×1375MM seamless tubes, manufactured with a Bright Annealed (BA) surface, ensuring a smooth, oxide-free finish that enhances both corrosion resistance and cleanliness.

Key Features

-

Material: TP321 Stainless Steel (1.4541, UNS S32100)

-

Standard: ASTM A213 / ASME SA213

-

Type: Seamless Tube (SMLS)

-

Size: 18 mm OD × 1.0 mm WT × 1375 mm Length

-

Surface Finish: Bright Annealed (BA)

-

Stabilization: Titanium added to improve weldability and prevent carbide precipitation

-

Applications: Heat Exchangers, Boilers, Chemical & Petrochemical Plants

Specifications

| Item | Details |

|---|---|

| Standards | ASTM A213 / ASME SA213 |

| Material | TP321 Stainless Steel (1.4541, UNS S32100) |

| Type | Seamless Tube |

| Size | 18×1.0MW×1375MM |

| Surface Finish | Bright Annealed |

| Applications | Heat Exchangers, Boilers, Power Plants, Refinery Piping, Chemical Plants |

Advantages of TP321 (1.4541)

-

High Temperature Resistance – maintains strength up to 870°C (1600°F).

-

Titanium Stabilization – prevents intergranular corrosion after welding.

-

Oxidation Resistance – effective in continuous service at high temperatures.

-

Bright Annealed Finish – smooth and clean surface improves corrosion resistance and fluid flow.

-

Reliability – suitable for demanding heat exchanger and boiler applications.

Applications

-

Heat Exchangers – for thermal energy transfer in power and petrochemical industries.

-

Boilers & Superheaters – tubes operating in elevated temperatures.

-

Petrochemical Plants – refinery piping, catalytic equipment.

-

Power Generation – condenser and boiler piping systems.

-

Chemical Industry – chloride and acid service environments.

Quality Assurance

DLSS ensures strict control for every TP321 seamless tube:

-

Bright Annealed Processing – oxide-free, corrosion-resistant surface.

-

PMI Testing – verifies correct grade 1.4541 (TP321).

-

Dimensional Inspection – ensures tight tolerances for heat exchanger use.

-

NDT (ET/UT) – available upon request for defect detection.

-

Third-Party Inspection – SGS, BV, TUV, LR certifications supplied if required.

FAQ

Q1: Why choose TP321 over TP304 for heat exchangers?

A1: TP321 is titanium-stabilized, providing better high-temperature strength and preventing intergranular corrosion after welding.

Q2: What is Bright Annealed finish?

A2: BA finish is a controlled heat treatment in a protective atmosphere that produces a smooth, reflective surface, improving corrosion resistance and cleanliness.

Q3: Is TP321 suitable for chloride environments?

A3: While TP321 has good resistance, for high chloride service, duplex or super duplex stainless steels are recommended.

Why Choose DLSS?

-

30+ years of manufacturing experience in stainless steel seamless tubes.

-

Trusted by global EPCs and end users for critical heat exchanger projects.

-

Comprehensive testing & quality assurance to meet ASTM/ASME requirements.

-

Seaworthy export packaging with PE caps and wooden cases.