Introduction

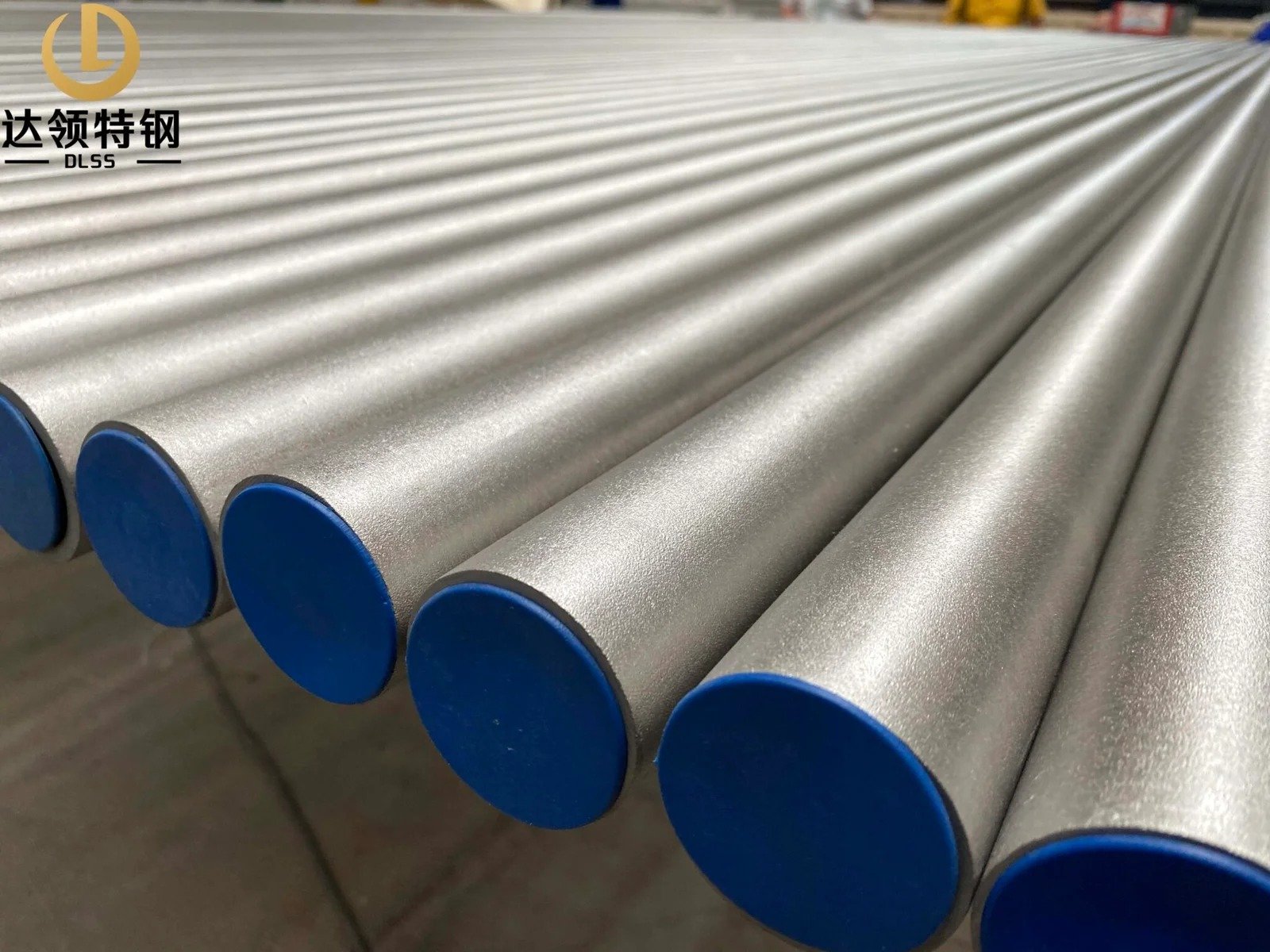

The ASTM A269/A213 TP316/316L Seamless Tube is a precision-engineered stainless steel tube widely used in shipyards and marine systems. With the combination of TP316 and TP316L grades, this product offers both superior corrosion resistance and excellent weldability, making it ideal for shipbuilding, seawater piping, and heat exchangers.

DLSS supplies 4 mm OD × 0.5 mm wall × 6000 mm length tubes, manufactured to ASTM A269/A213 standards, with Bright Annealed (BA) surface finish for smoothness, cleanliness, and improved resistance against marine corrosion.

Key Features

-

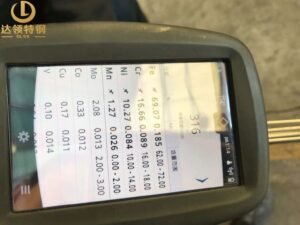

Material: Stainless Steel TP316 / TP316L

-

Standards: ASTM A269 / ASTM A213

-

Type: Seamless Tube (SMLS)

-

Size: 4×0.5 MW × 6000 mm

-

Surface Finish: Bright Annealed (BA) – smooth and oxide-free

-

Application: Shipyard piping, seawater cooling, heat exchangers, condensers

Specifications

| Item | Details |

|---|---|

| Standards | ASTM A269 / ASTM A213 |

| Material | Stainless Steel TP316 / TP316L |

| Type | Seamless Tube |

| Size | 4 mm OD × 0.5 mm WT × 6000 mm Length |

| Surface Finish | Bright Annealed |

| Applications | Shipbuilding, Offshore Marine, Heat Exchangers, Condensers, Chemical Plants |

Advantages of TP316/316L

-

Molybdenum Addition (2–3%) – superior resistance to seawater and chloride corrosion compared to TP304.

-

Dual Grade Option – TP316 provides higher strength, TP316L prevents intergranular corrosion during welding.

-

Bright Annealed Surface – smooth internal finish reduces contamination and enhances durability.

-

Thin-Wall Precision – suitable for instrumentation, condensers, and compact shipyard piping systems.

Applications

-

Shipyards – seawater cooling, exhaust systems, on-deck piping.

-

Marine Engineering – desalination and offshore installations.

-

Heat Exchangers & Condensers – efficient heat transfer with corrosion resistance.

-

Chemical Processing Plants – acid/chloride service pipelines.

-

Power Plants – boiler tubes and auxiliary piping systems.

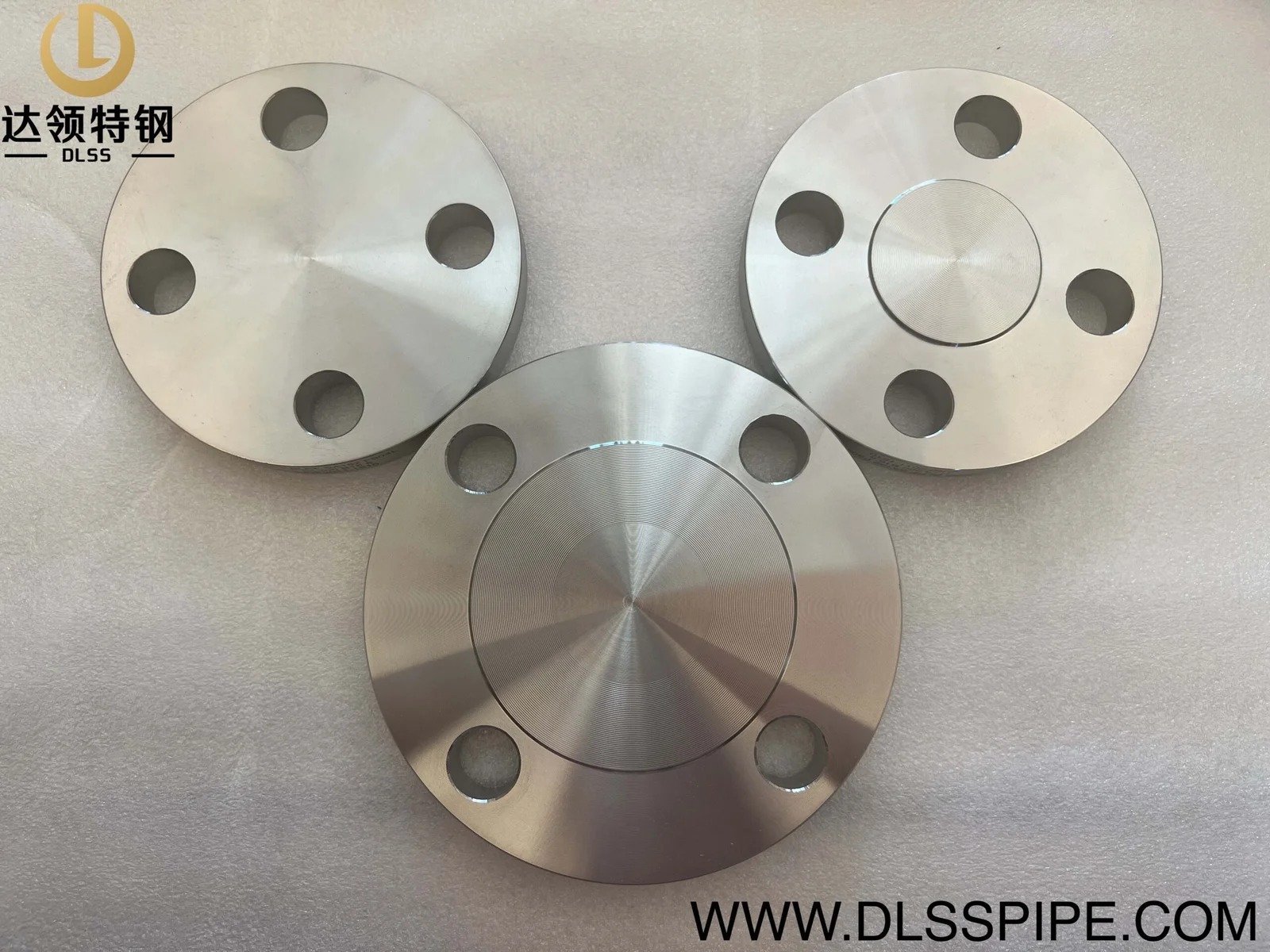

Quality Assurance

DLSS ensures all seamless tubes meet strict quality standards:

-

Bright Annealed Processing – oxide-free, clean surfaces.

-

Dimensional Control – tight tolerances for precision use.

-

NDT (ET, UT) – ensures no hidden defects.

-

Third-Party Inspection – SGS, BV, TUV available upon request.

FAQ

Q1: What is the benefit of dual grade 316/316L?

A1: It allows flexibility – 316 ensures strength, while 316L provides weldability and resistance to intergranular corrosion.

Q2: Why Bright Annealed finish for marine use?

A2: It ensures a smoother surface, improving corrosion resistance and reducing fouling in seawater service.

Q3: Is this size suitable for shipyards?

A3: Yes, the thin wall 4×0.5 mm tube is commonly used for instrumentation, condensers, and auxiliary systems in shipyards.

Why Choose DLSS?

-

Over 30 years’ experience supplying stainless steel tubing for shipyards and marine industries.

-

Certified manufacturing with ASTM/ASME standards.

-

Reliable export packaging (PE caps + wooden cases).

-

Global references in offshore, oil & gas, and power projects.