Introduction

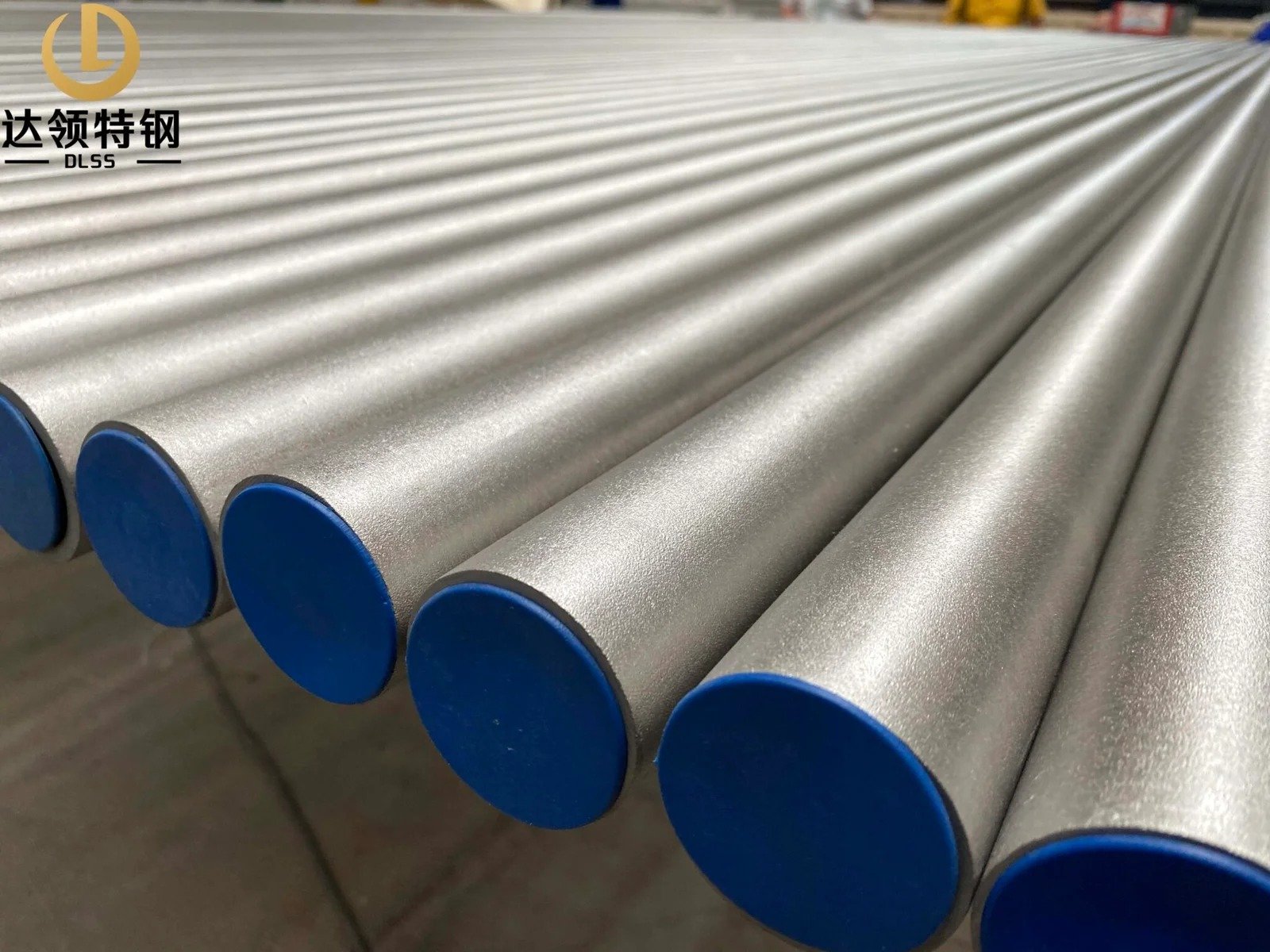

The ASTM A269 TP316L Seamless Tube is a high-quality stainless steel tube designed for shipbuilding and marine engineering applications. Manufactured with bright annealed surface finish, this tube provides superior corrosion resistance, smooth internal surface, and excellent mechanical properties.

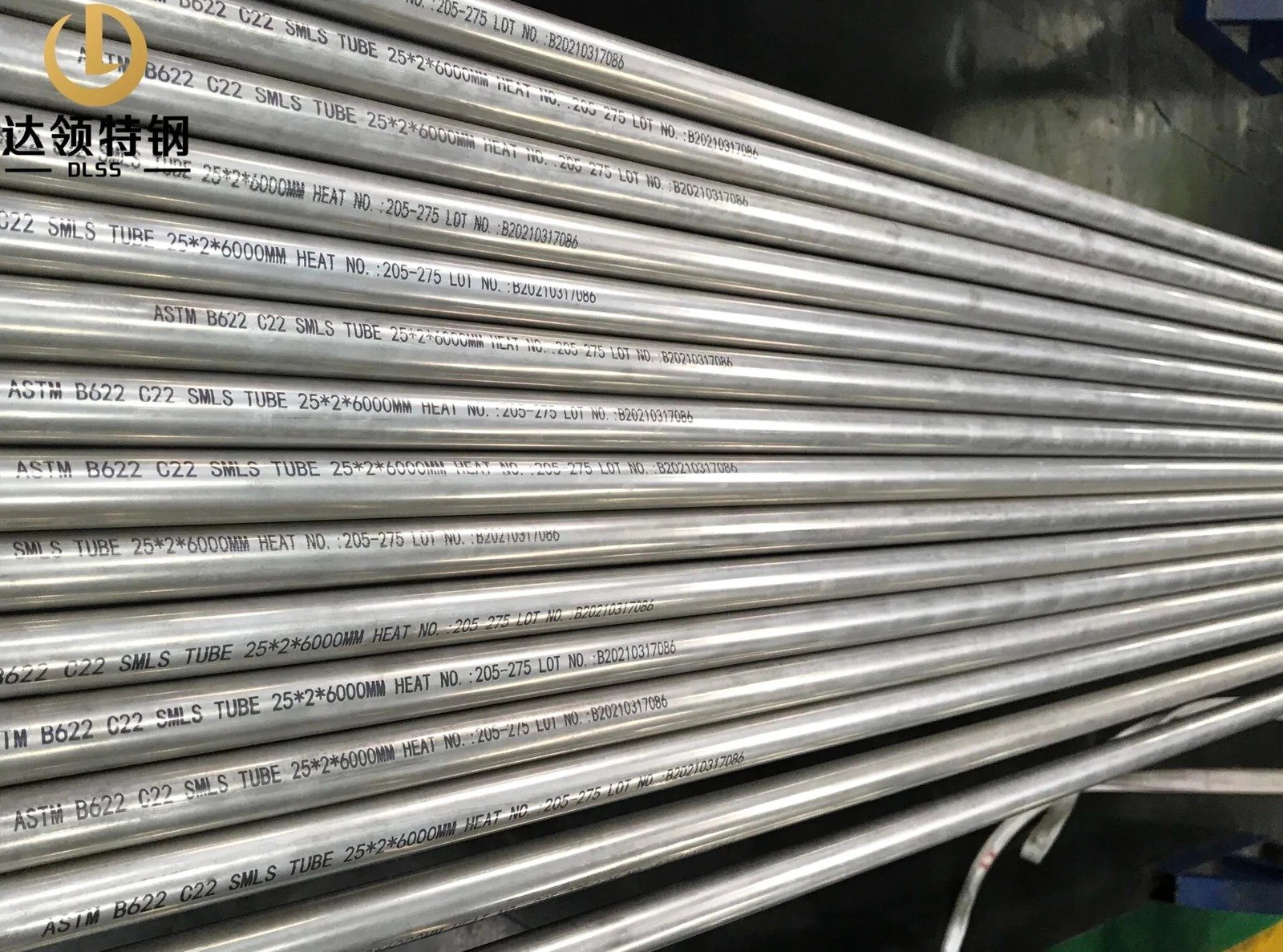

DLSS supplies 22×2.0×6000MM seamless tubes, fully compliant with ASTM A269, and tested with 100% heat treatment (HT) and 100% eddy current testing (ET) to guarantee reliability for critical shipyard projects.

Key Features

-

Material: Stainless Steel TP316L (low-carbon austenitic stainless steel)

-

Standard: ASTM A269

-

Type: Seamless Tube (SMLS)

-

Size: 22 mm OD × 2.0 mm WT × 6000 mm Length

-

Surface Finish: Bright Annealed (BA) for smooth and clean surface

-

Testing: 100% HT + 100% ET for structural and surface integrity

-

Application: Shipbuilding, marine piping, heat exchangers, and condensers

Specifications

| Item | Details |

|---|---|

| Standard | ASTM A269 |

| Material | TP316L Stainless Steel (UNS S31603) |

| Type | Seamless Bright Annealed Tube |

| Size | 22×2.0×6000MM |

| Testing | 100% Heat Treatment + 100% Eddy Current Test |

| Surface Finish | Bright Annealed (BA) |

| Applications | Shipbuilding, Marine Systems, Heat Exchangers, Condensers, Chemical Piping |

Advantages of TP316L Stainless Steel

-

Corrosion Resistance – excellent in seawater, chloride, and acidic environments.

-

Low Carbon Grade (L) – prevents carbide precipitation, ensuring weldability.

-

Bright Annealed Finish – smooth internal surface, reduced contamination risk.

-

Durability – long service life in shipyards and offshore applications.

Applications

-

Shipbuilding Industry – seawater cooling, piping, exhaust systems.

-

Marine Engineering – desalination plants, offshore platforms.

-

Heat Exchangers & Condensers – efficient thermal conductivity with clean surfaces.

-

Chemical & Petrochemical Plants – corrosion-resistant piping systems.

-

Power Generation – boiler and condenser tubing in harsh environments.

Quality Assurance

DLSS ensures every tube meets stringent international standards:

-

100% Heat Treatment (HT) for balanced microstructure.

-

100% Eddy Current Testing (ET) to detect surface defects.

-

PMI, Hydrostatic & Dimensional Testing available.

-

Third-Party Inspection (SGS, BV, TUV, LR) provided upon request.

FAQ

Q1: Why choose TP316L over TP304 for shipbuilding?

A1: TP316L contains molybdenum (2–3%), giving much better resistance to pitting and crevice corrosion in seawater compared to TP304.

Q2: What is Bright Annealed finish?

A2: Bright annealing is a controlled heat treatment in a protective atmosphere, producing a mirror-like smooth surface that enhances corrosion resistance.

Q3: What does 100% ET mean?

A3: Eddy Current Testing ensures no surface cracks or defects, guaranteeing reliability in critical marine systems.

Why Choose DLSS?

-

Specialized in stainless steel seamless tubes for marine, offshore, and power applications.

-

Over 30 years of experience with global shipyards and EPC contractors.

-

Comprehensive testing & certifications to meet end-user requirements.

-

Export-ready packaging with PE caps, plastic wrapping, and seaworthy wooden cases.