Introduction

DLSS supplies ASTM A789 S32750 Super Duplex Seamless Tubes (19×2.4mm) with a Bright Annealed (BA) finish, engineered for demanding applications in heat exchangers, condensers, and seawater systems. Manufactured from UNS S32750 (1.4410) Super Duplex stainless steel, these tubes provide exceptional strength and outstanding resistance to corrosion in aggressive environments.

Specifications

| Item | Details |

|---|---|

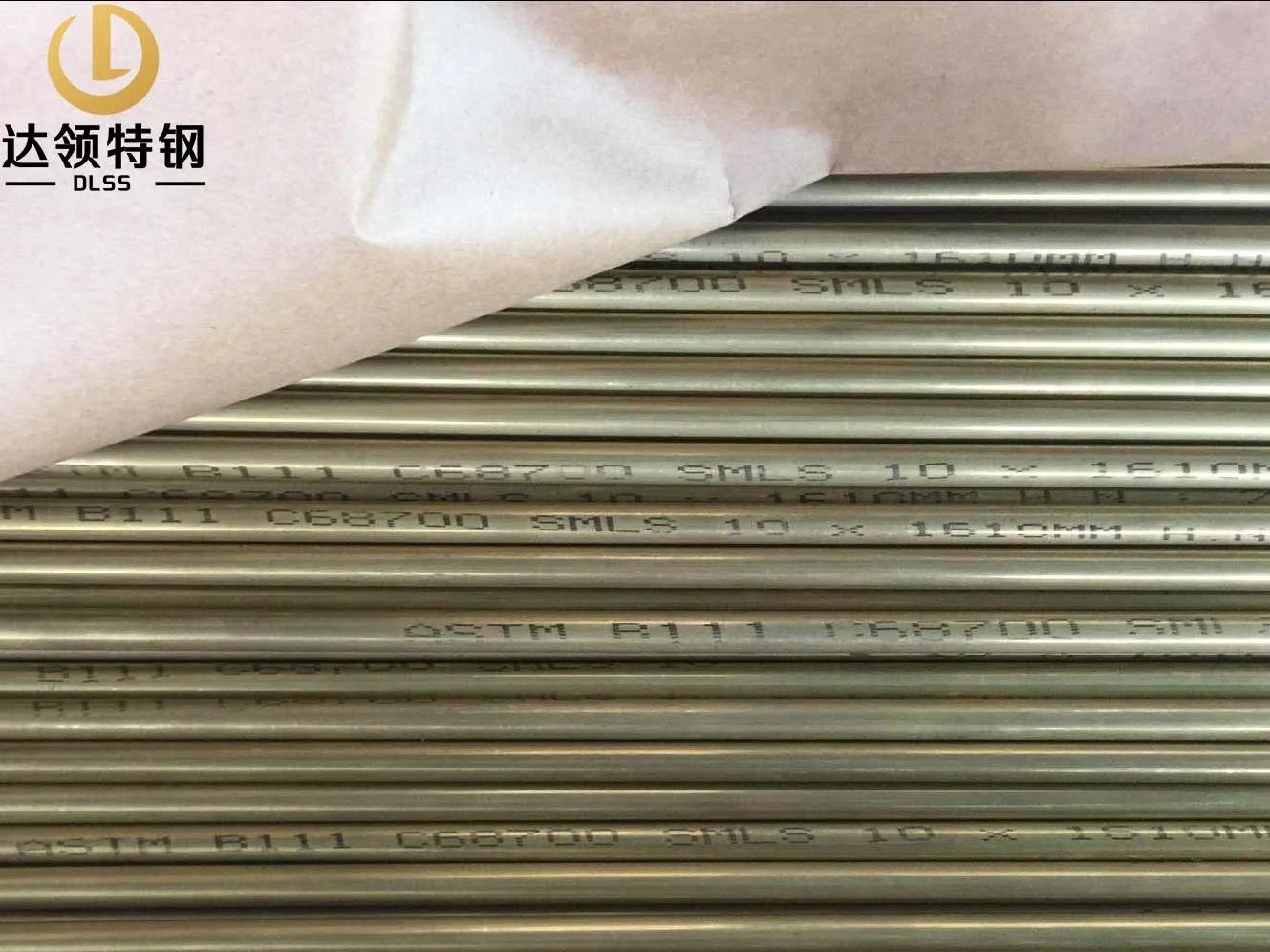

| Standard | ASTM A789 / UNS S32750 (Super Duplex, 1.4410) |

| Size | OD 19 mm × WT 2.4 mm |

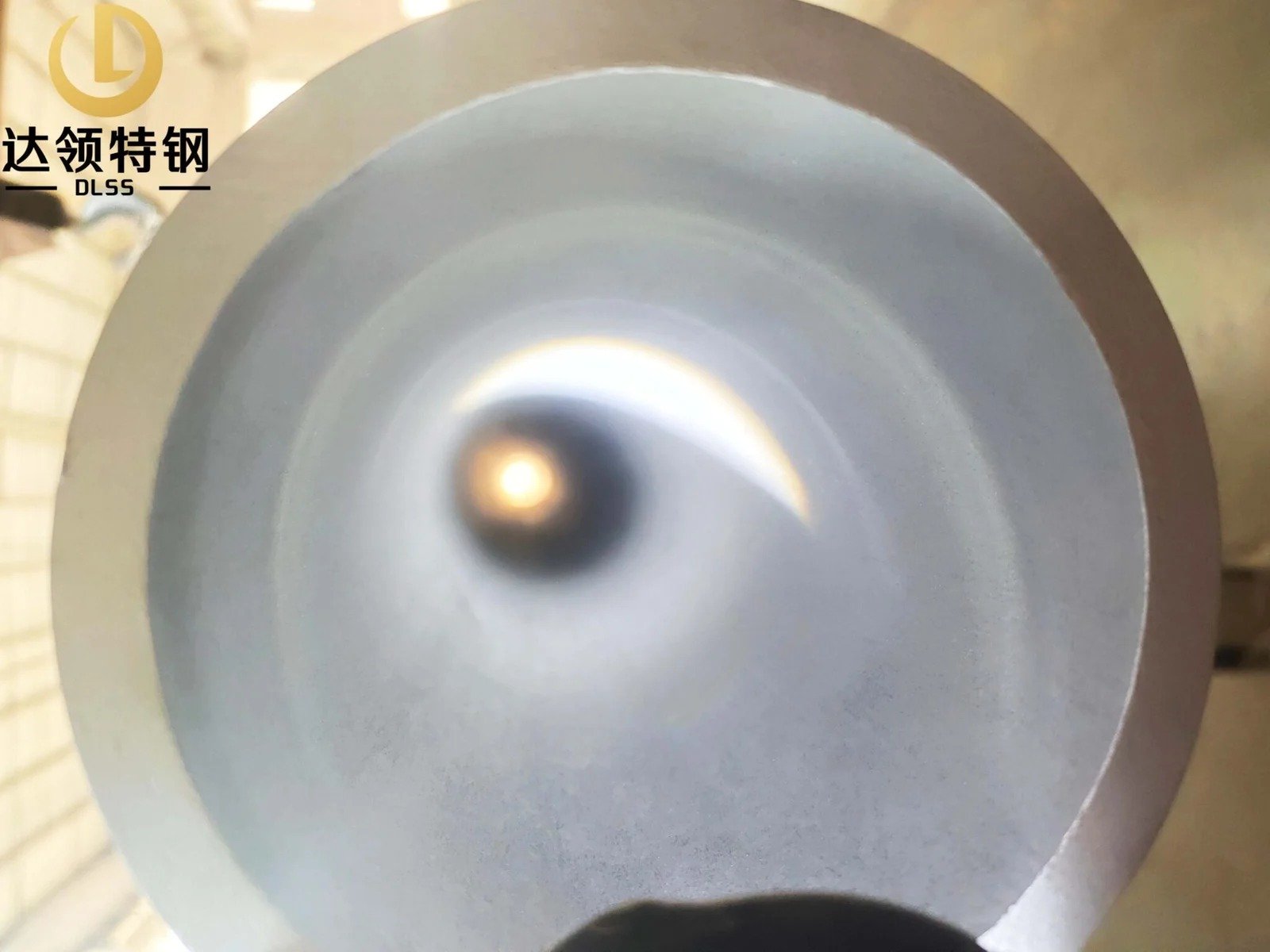

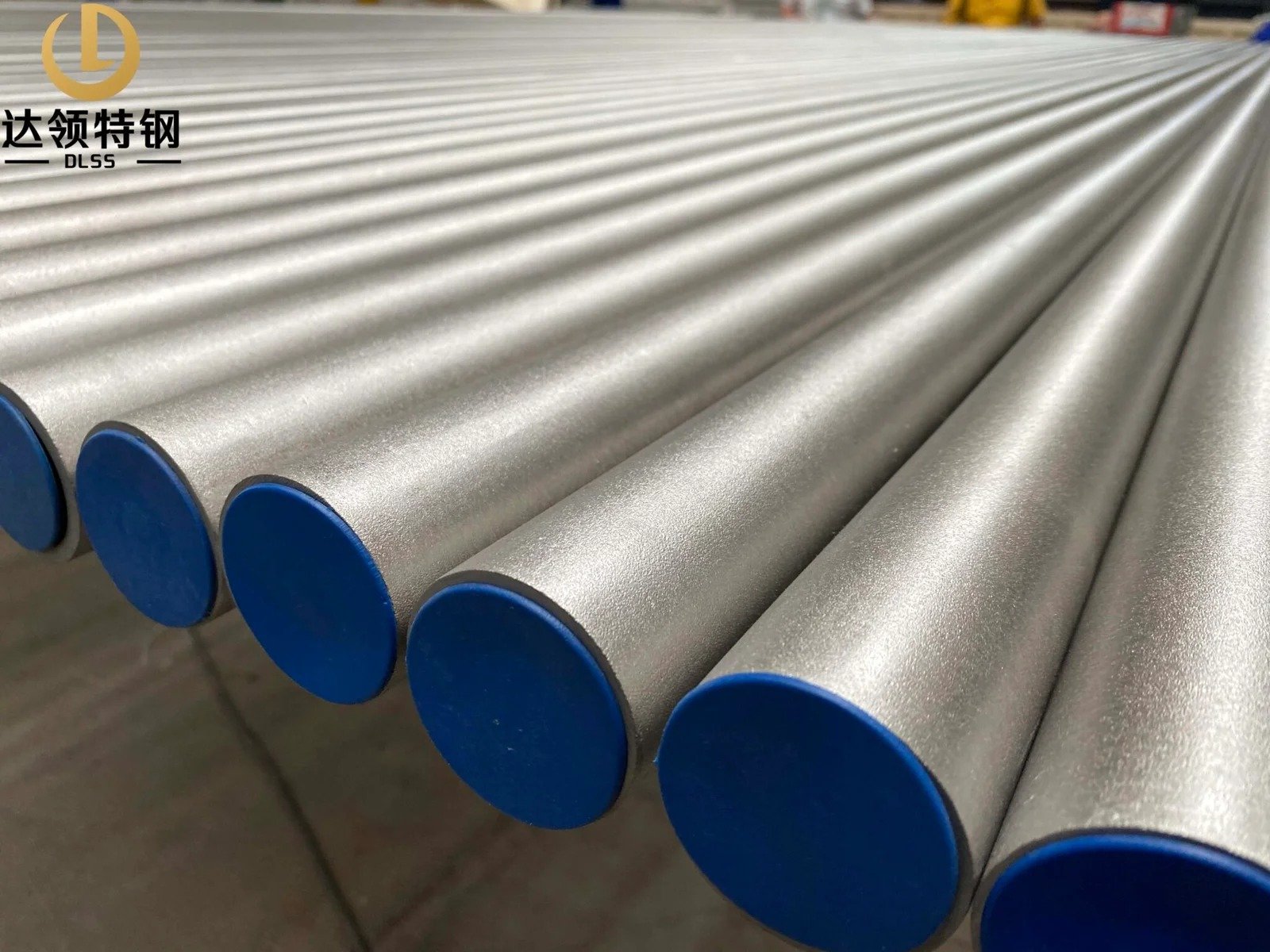

| Type | Seamless, Bright Annealed (BA) finish |

| Mechanical Properties | Yield ≥ 550 MPa, Tensile ≥ 795 MPa |

| Corrosion Resistance | Excellent resistance to pitting, crevice corrosion, and SCC in chloride media |

| Surface Finish | Bright Annealed, smooth and contamination-free |

Key Features

-

High Strength: Nearly twice the yield strength of standard austenitic stainless steels.

-

Corrosion Resistance: Reliable protection against seawater, brine, and chloride-rich environments.

-

Bright Annealed Finish: Clean, smooth surface reduces fouling and ensures long service life.

-

Seamless Structure: Superior pressure resistance and excellent dimensional accuracy.

Applications

-

Heat Exchangers (shell & tube type, condensers, evaporators)

-

Chemical & Petrochemical Processing Plants

-

Offshore Oil & Gas Industry (subsea pipelines, risers)

-

Desalination Plants & Seawater Cooling Systems

-

Pulp & Paper Industry Equipment

Advantages of Choosing DLSS

-

Proven Expertise: 30+ years of stainless steel tube manufacturing and export.

-

Global Trust: Supplied to projects in 40+ countries worldwide.

-

Strict Quality Control: 100% tested with hydrostatic and eddy current inspections.

-

Packaging Assurance: Seaworthy packing with end caps and woven bags to ensure safe delivery.

Frequently Asked Questions (FAQ)

Q1: What is the advantage of ASTM A789 S32750 over 316L?

A1: S32750 offers nearly double the strength of 316L and much better resistance to chloride stress corrosion cracking, making it ideal for offshore and seawater environments.

Q2: Why choose Bright Annealed finish tubes?

A2: Bright Annealed tubes have smooth, clean surfaces that reduce fouling, scale formation, and contamination risk in heat exchangers.

Q3: Can DLSS supply customized lengths and U-bend tubes?

A3: Yes, we provide straight lengths, U-tubes, and cut-to-size options according to client specifications.

Q4: What inspection certificates are provided?

A4: Mill Test Certificate (EN 10204/3.1), and third-party inspection (BV, SGS, TUV, etc.) can be arranged upon request.