Introduction

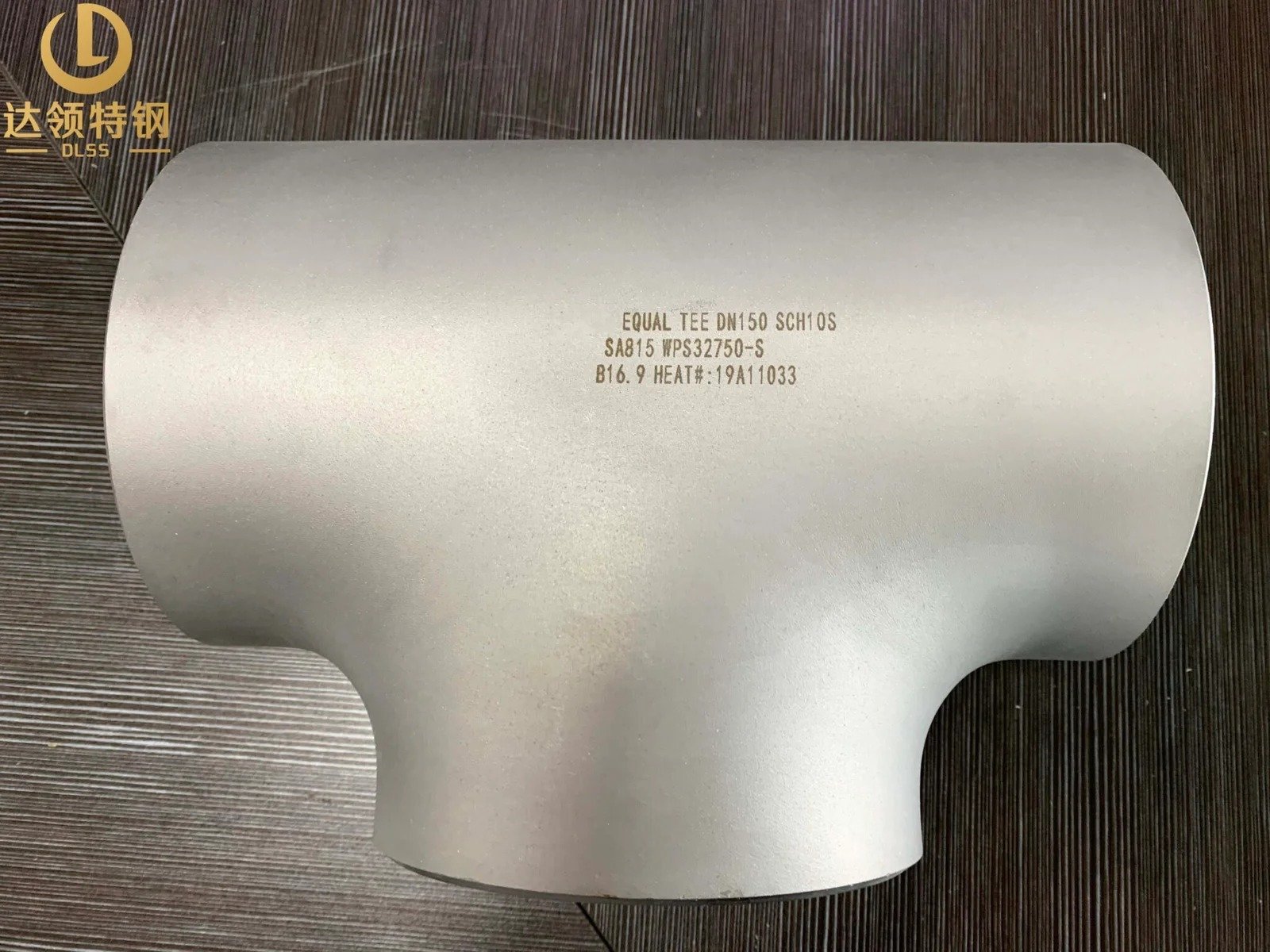

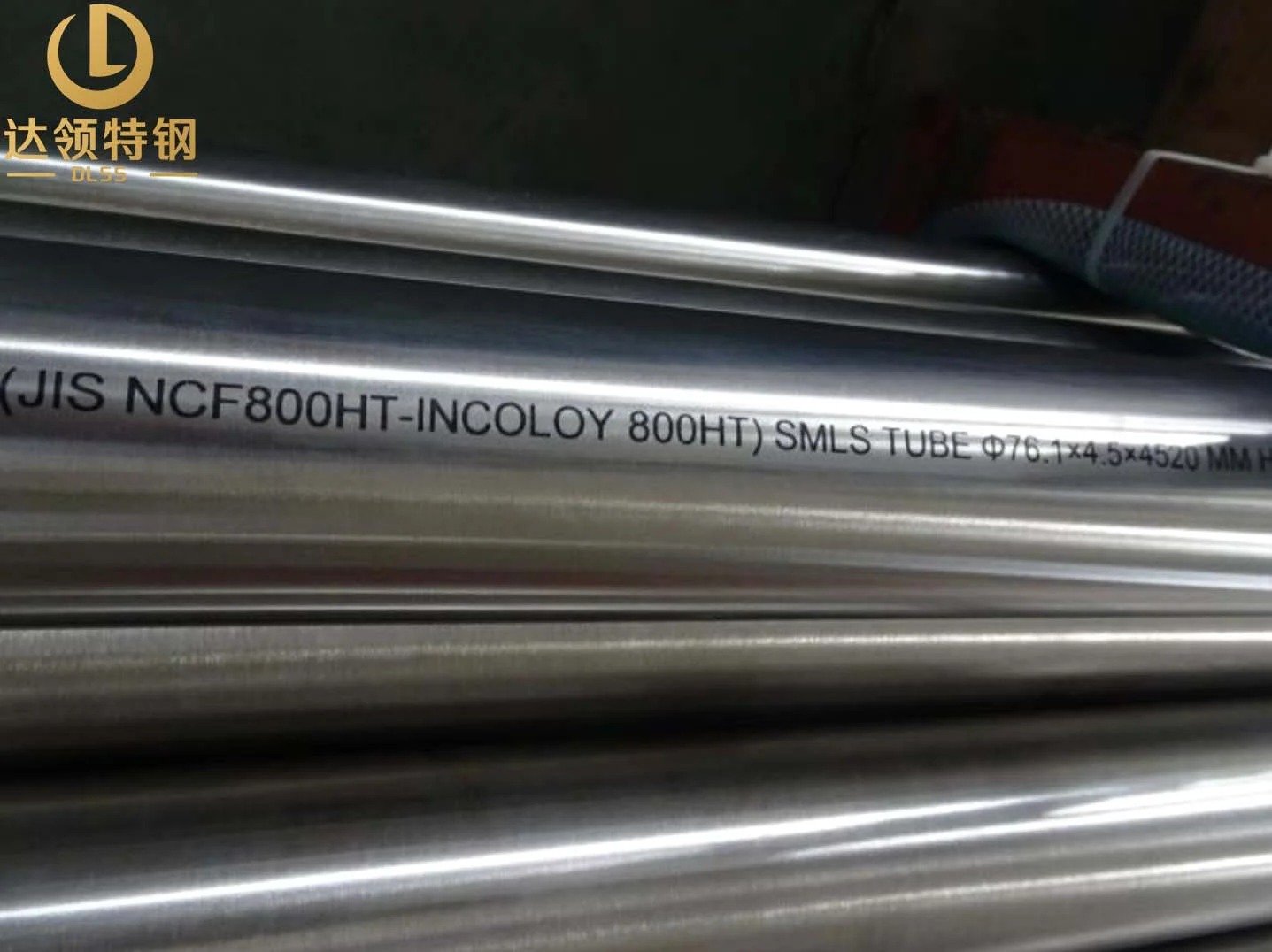

The ASTM A790 S32750 Seamless Pipe is a super duplex stainless steel pipe engineered for the world’s toughest environments. With its balanced austenite-ferrite microstructure, S32750 offers exceptional strength (yield ≥550 MPa) and excellent resistance to pitting, crevice corrosion, and stress corrosion cracking in chloride-rich conditions.

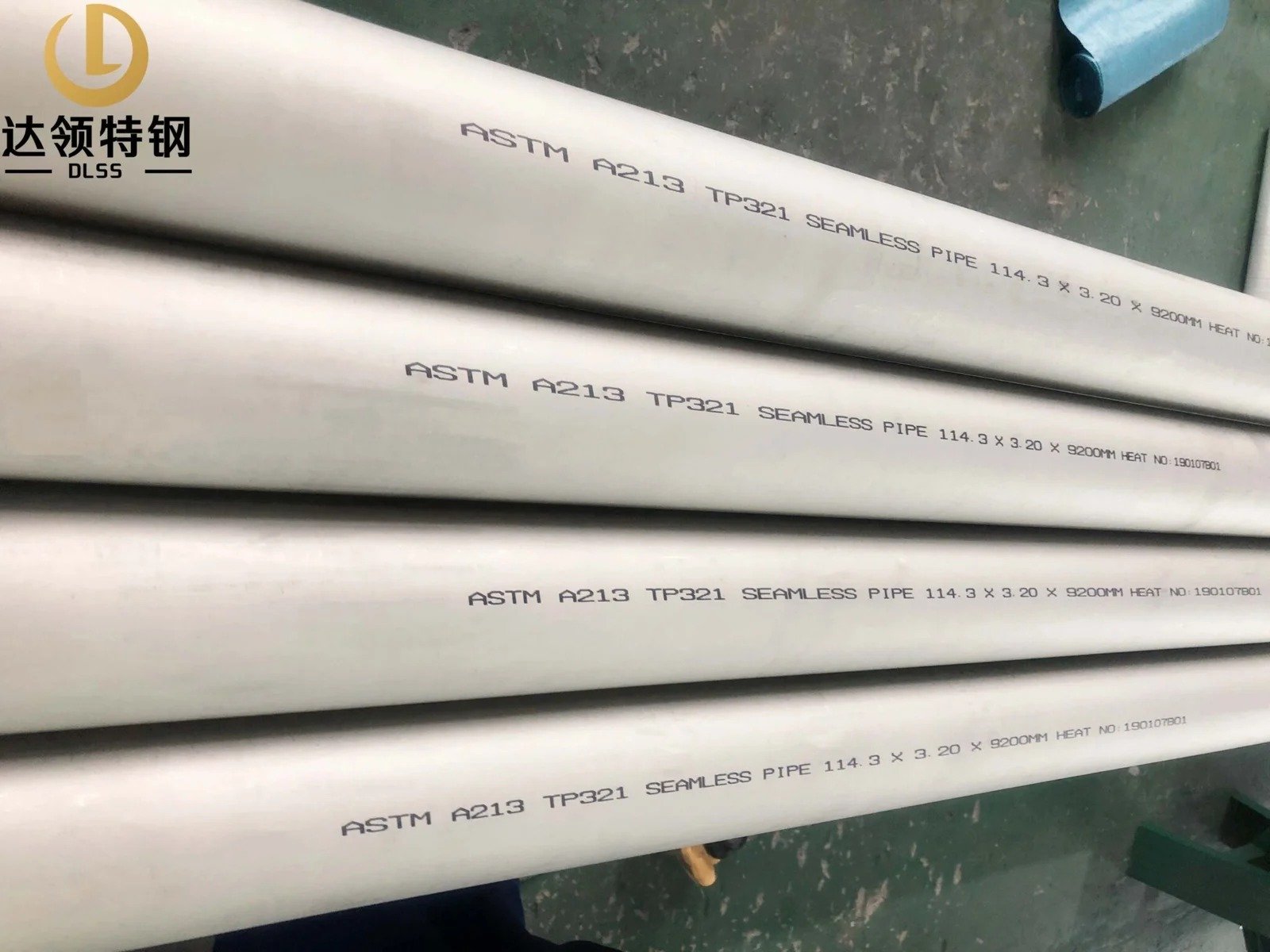

DLSS supplied DN100 SCH40S seamless pipes, 6000mm length, with pickled surface finish and 100% heat treatment (HT) to guarantee mechanical integrity and corrosion resistance. These pipes are widely used in offshore, marine, chemical, and power generation projects where performance and durability are critical.

Key Features

-

Material: Super Duplex Stainless Steel S32750 (UNS S32750)

-

Standard: ASTM A790

-

Type: Seamless Pipe (SMLS)

-

Size: DN100 (4″ Nominal Bore)

-

Schedule: SCH40S (medium wall, pressure service)

-

Length: 6000mm

-

Surface Finish: Pickled (removes scale and impurities, improves corrosion resistance)

-

Testing: 100% Heat Treatment (HT) to ensure duplex balance and strength

-

Strength: Yield ≥550 MPa, Tensile ≥800 MPa

Specifications

| Item | Details |

|---|---|

| Standard | ASTM A790 |

| Material | Super Duplex Stainless Steel S32750 |

| Type | Seamless Pipe (SMLS) |

| Size | DN100 (4″) |

| Wall Thickness | SCH40S |

| Length | 6000mm |

| Surface Finish | Pickled |

| Heat Treatment | 100% HT |

| Applications | Offshore, Marine, Oil & Gas, Chemical Plants, Power Generation |

Advantages of S32750 Super Duplex

-

High Strength – nearly twice the yield strength of 316L/904L stainless steels.

-

Excellent Corrosion Resistance – PREN > 40 ensures resistance to pitting and crevice corrosion in seawater and brine.

-

Chloride SCC Resistance – superior to austenitic and standard duplex steels.

-

Cost Efficiency – can replace higher nickel alloys in many harsh environments.

-

Long Service Life – ideal for demanding offshore and petrochemical operations.

Applications

-

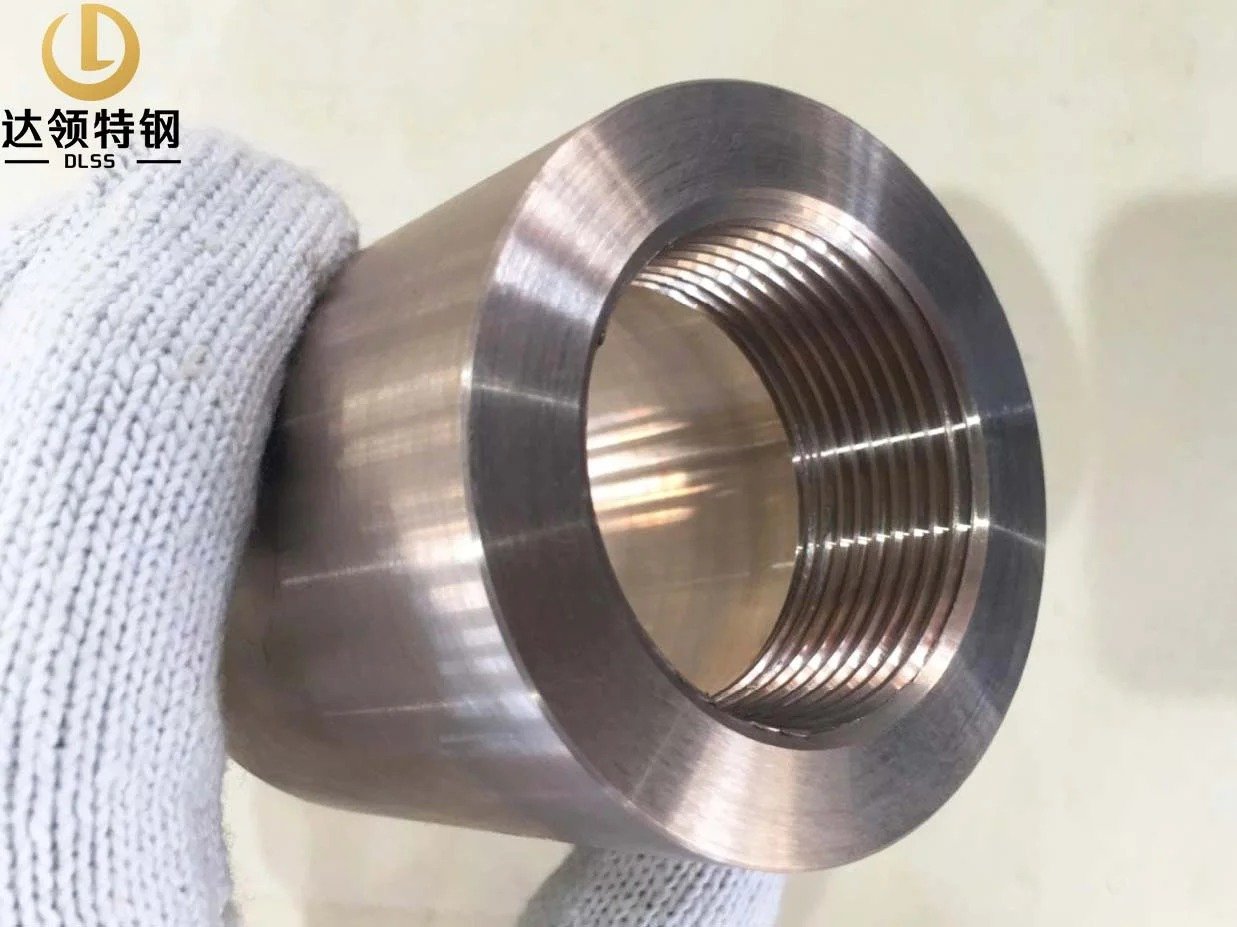

Offshore & Marine – risers, subsea flowlines, seawater injection systems.

-

Oil & Gas Industry – process piping, manifolds, heat exchangers.

-

Chemical Processing – piping systems for acids, chlorides, and aggressive media.

-

Power Generation – boiler tubes, condensers, high-pressure piping.

-

Desalination Plants – seawater intake, brine discharge systems.

Quality Assurance

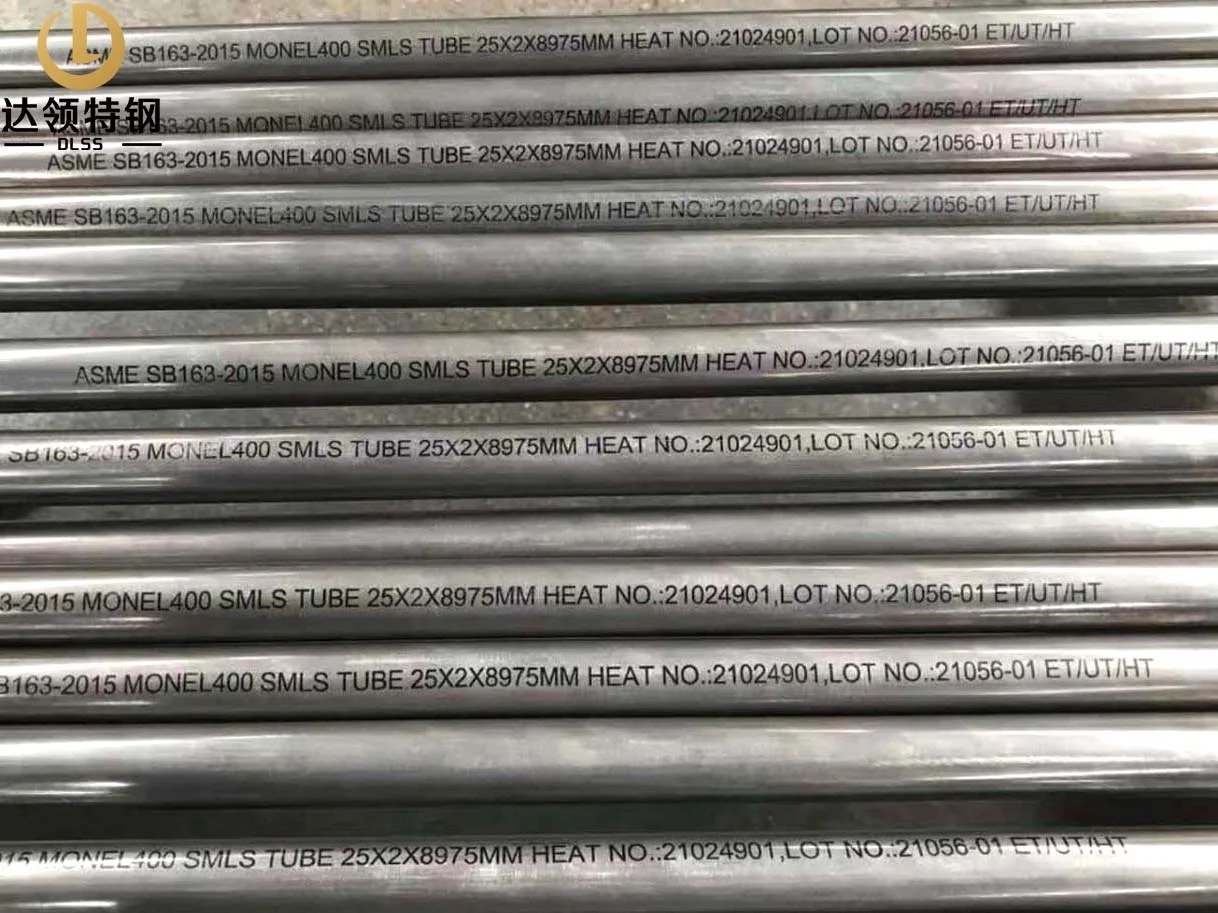

DLSS ensures strict quality control for every pipe:

-

100% Heat Treatment (HT) – ensures correct duplex microstructure.

-

PMI Testing – verifies chemical composition.

-

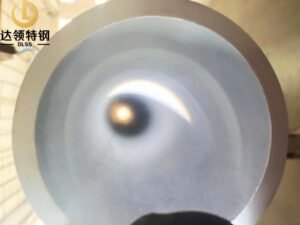

NDT (UT, ET) – detects internal & surface defects.

-

Hydrostatic Testing – ensures pressure resistance.

-

Third-Party Inspection – SGS, BV, TUV, LR available upon request.

FAQ

Q1: What makes S32750 better than standard duplex S32205?

A1: S32750 offers higher strength and corrosion resistance, especially in seawater and chloride-rich environments, making it suitable for offshore and subsea applications.

Q2: Why is heat treatment important?

A2: 100% HT ensures the right balance of ferrite and austenite phases, giving the pipe maximum strength and corrosion resistance.

Q3: What is the benefit of pickled surface finish?

A3: Pickling removes oxides and scale, leaving a clean, smooth surface that improves corrosion resistance and makes the pipe easier to weld.

Why Choose DLSS?

-

30+ years of experience in stainless steel & duplex pipe manufacturing.

-

Global supply references in offshore, oil & gas, desalination, and power projects.

-

Comprehensive testing & certifications for guaranteed quality.

-

Seaworthy export packaging with PE caps, plastic wrap, and wooden cases.