Introduction

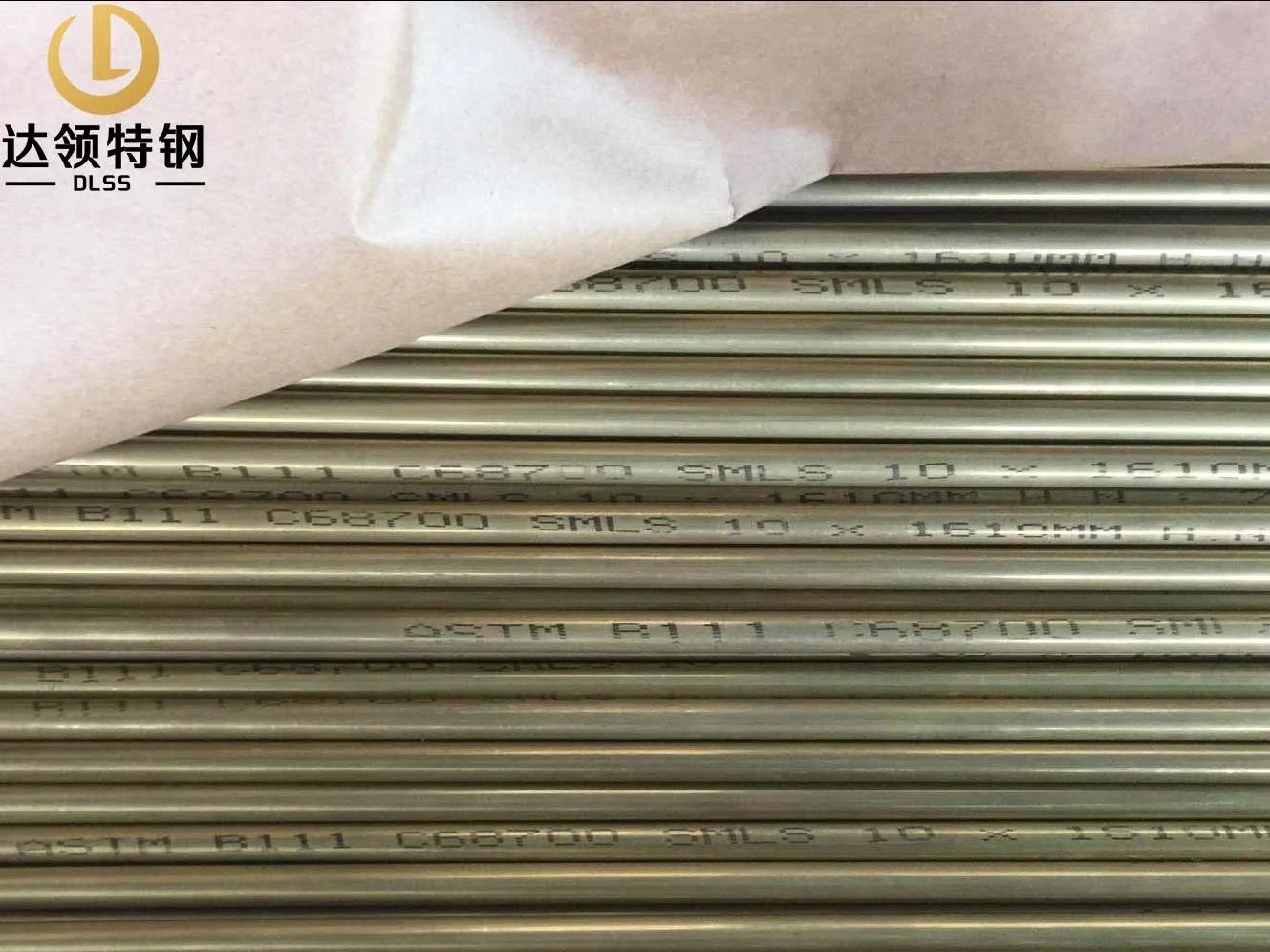

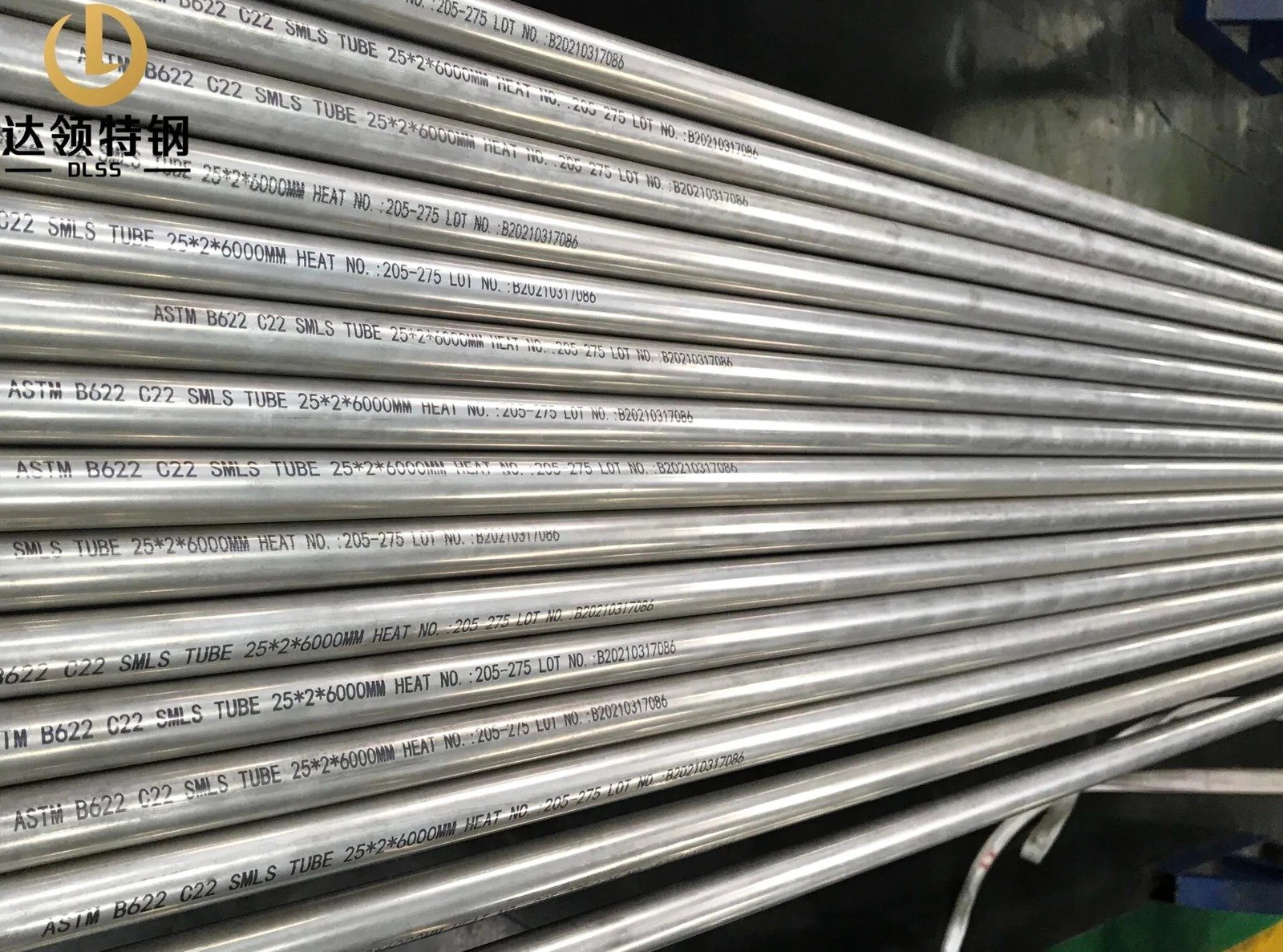

ASTM B111 C70600 (O61) Seamless Tube is one of the most widely used copper-nickel alloys for condenser and heat exchanger applications. DLSS supplies tubes in the size 16 mm OD × 1.0 mm wall thickness × 3000 mm length, manufactured in accordance with ASTM B111, and each tube is subjected to 100% Eddy Current Testing to ensure flawless quality and performance.

C70600, also known as 90/10 Copper-Nickel (CuNi 90/10), offers an outstanding combination of corrosion resistance, durability, and heat transfer efficiency, making it the preferred material for power plants, desalination systems, and marine cooling applications.

Material Overview – C70600 Copper-Nickel

C70600 (UNS C70600 / CuNi 90-10) is a copper alloy containing approximately 90% copper and 10% nickel, with controlled amounts of iron and manganese to enhance seawater corrosion resistance.

Key advantages of ASTM B111 C70600 (O61) Seamless Tube:

-

Excellent resistance to seawater corrosion and biofouling

-

High resistance to erosion and impingement attack in flowing seawater

-

Good mechanical strength and thermal conductivity

-

Long service life in marine and industrial environments

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B111 |

| Material | C70600 (CuNi 90/10) – O61 Annealed |

| Size | 16 mm OD × 1.0 mm Wall Thickness × 3000 mm Length |

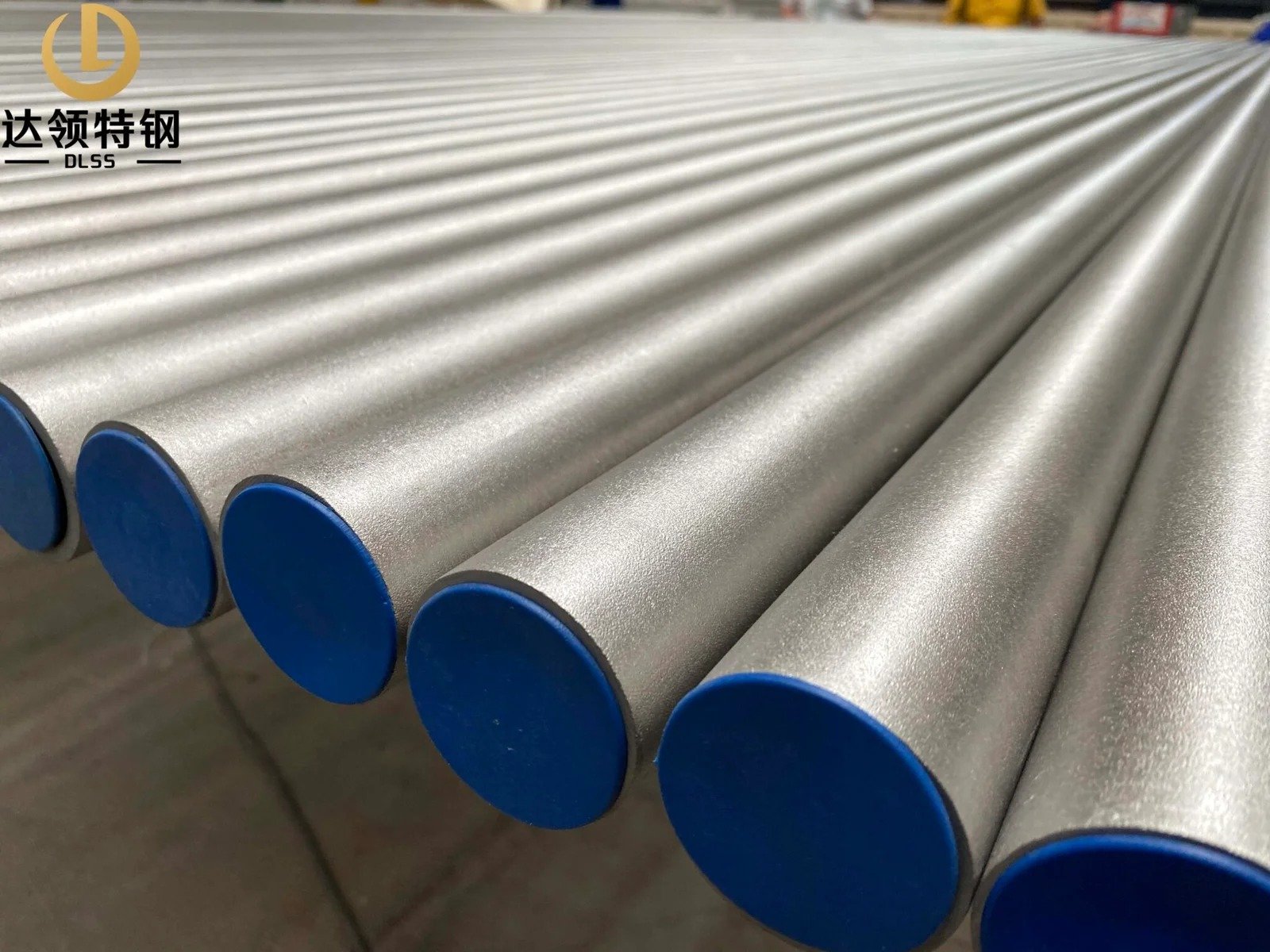

| Type | Seamless Tube |

| Testing | 100% Eddy Current Testing |

| Applications | Condenser, Heat Exchanger, Seawater Cooling Systems |

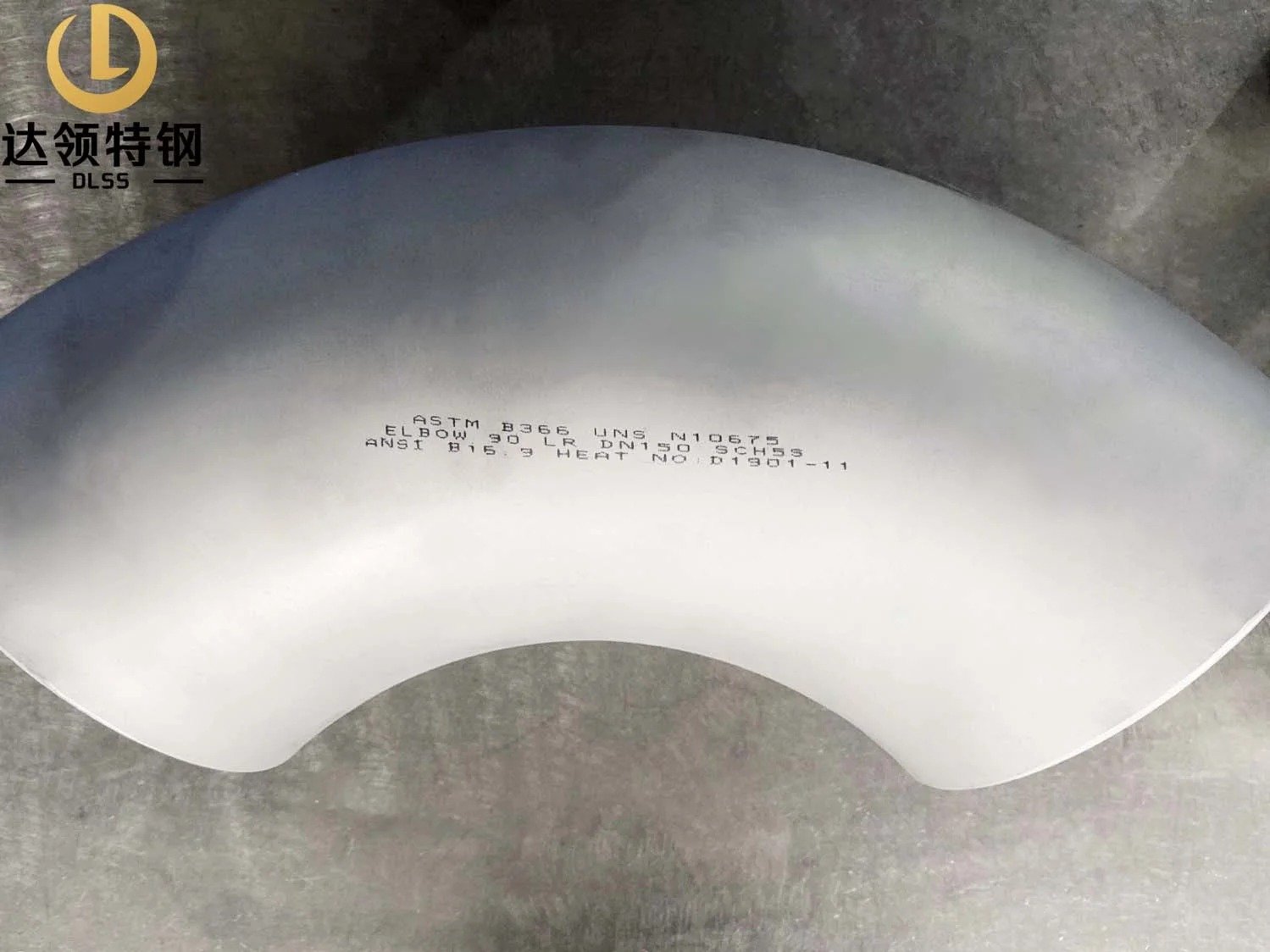

Applications

-

Power Plant Condensers

-

Desalination Plants

-

Shipbuilding & Marine Engineering (cooling water systems, condensers)

-

Chemical & Petrochemical Plants

-

Offshore Oil & Gas Platforms

Why Choose DLSS C70600 Seamless Tubes?

-

Strict ASTM B111 Compliance – Manufactured to international standards

-

100% Eddy Current Testing – Guarantee of defect-free performance

-

High Reliability in Seawater Environments – Proven CuNi 90/10 corrosion resistance

-

Custom Supply Options – Straight lengths, U-bends, and cut-to-size available

-

Export-Ready Packaging – Bundles or ISPM-15 wooden cases with end caps

Frequently Asked Questions (FAQ)

Q1: What does O61 mean in C70600 tubes?

A1: O61 refers to the annealed condition, which improves ductility and workability.

Q2: Why is CuNi 90/10 preferred for condensers?

A2: It provides excellent resistance to seawater corrosion, erosion, and biofouling, ensuring long-term service life.

Q3: Can DLSS supply other sizes of ASTM B111 tubes?

A3: Yes, we supply a wide range of sizes, wall thicknesses, and lengths to meet project requirements.

Q4: Are third-party inspections available?

A4: Yes, SGS, BV, TUV, or client-nominated agencies can witness testing before shipment.