Product Description

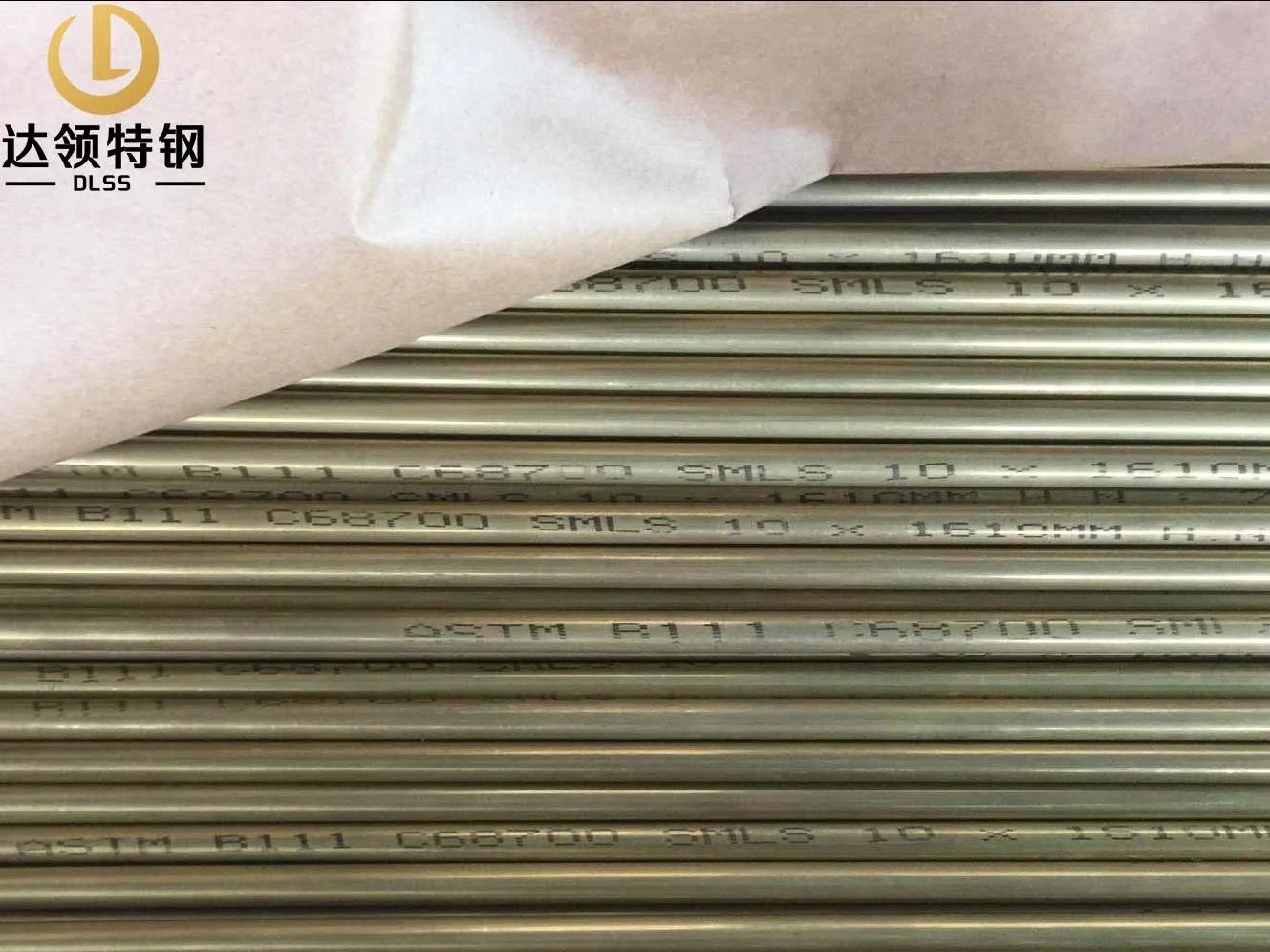

DLSS supplies ASTM B111 C70600 (O61) seamless tubes in size 19.05 mm OD × 1.65 mm wall thickness × 1330 mm length, manufactured from Copper-Nickel 90/10 (CuNi 90/10) alloy. These tubes are widely used in heat exchangers, condensers, seawater cooling, and marine engineering equipment.

Each tube is delivered in O61 annealed condition, ensuring excellent ductility and fabrication performance. To guarantee reliability, the tubes undergo 100% Eddy Current Testing (ET) for surface defect detection and have successfully passed third-party inspection (SGS, BV, TUV), meeting international standards for critical projects.

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B111 |

| Material | C70600 Copper-Nickel (90/10) |

| Condition | O61 (Annealed) |

| Type | Seamless Tube |

| Size | 19.05 mm OD × 1.65 mm WT × 1330 mm Length |

| Testing | 100% Eddy Current Testing (ET) |

| Inspection | Third-Party Inspection Passed (SGS/BV/TUV) |

| Applications | Heat exchangers, condensers, seawater systems, offshore & marine piping |

Key Features

-

Seamless CuNi 90/10 Construction – Reliable corrosion resistance in seawater and brine.

-

100% Eddy Current Tested – Ensures defect-free performance for critical systems.

-

O61 Annealed Condition – Good ductility and ease of bending for U-tubes and bundles.

-

Third-Party Certified – SGS/BV/TUV inspections confirm international compliance.

-

Durable Service Life – Proven in desalination, offshore oil & gas, and power plants.

Applications

-

Marine & Offshore Systems – seawater cooling, ballast, and firewater lines.

-

Desalination Plants – resistant to brine and high-salinity environments.

-

Power Plant Condensers – seawater-cooled tubing bundles.

-

Heat Exchangers – industrial and petrochemical cooling applications.

-

Shipbuilding & Engine Cooling – durable condenser and cooler tubes.

Why Choose DLSS?

-

Complete CuNi Solutions – pipes, tubes, flanges, fittings in C70600 material.

-

Strict Quality Control – 100% ET + third-party inspection ensures reliability.

-

Export Packaging – tubes capped, plastic wrapped, seaworthy wooden cases.

-

Global Supply Experience – trusted supplier to EPC contractors and end-users worldwide.

Frequently Asked Questions (FAQ)

Q1: What does O61 mean for C70600 tubes?

A1: O61 refers to the annealed condition, providing better ductility for bending and fabrication.

Q2: Why use Eddy Current Testing (ET)?

A2: ET detects surface and near-surface defects, ensuring each tube is flawless before shipment.

Q3: What third-party inspections are available?

A3: SGS, BV, TUV, or client-nominated agencies can certify dimensions, chemistry, and NDT results.

Q4: What industries commonly use C70600 tubes?

A4: Power generation, desalination, shipbuilding, petrochemical, and offshore oil & gas.