Introduction

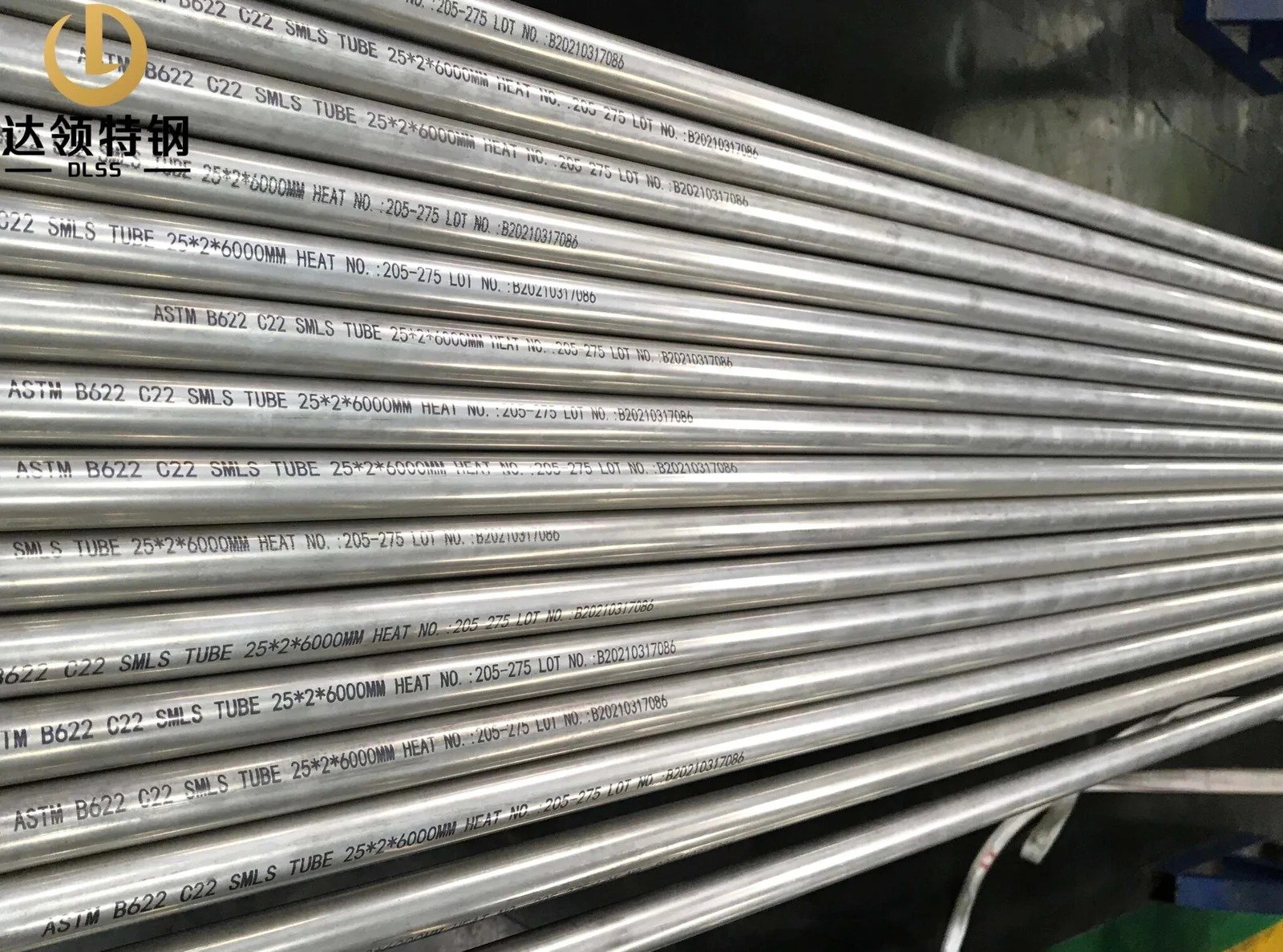

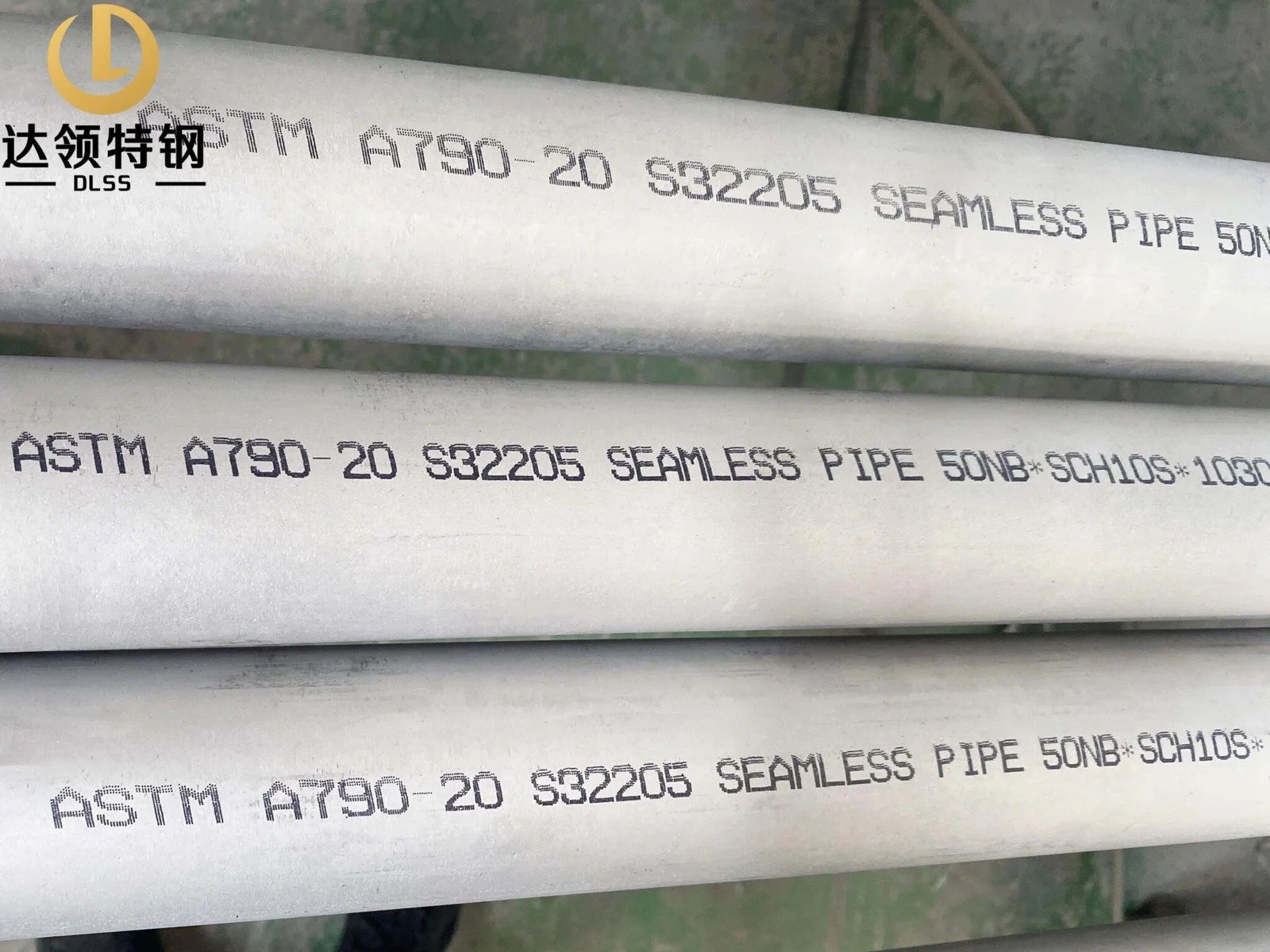

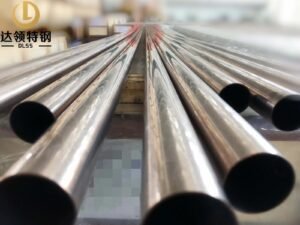

ASTM B111 C70600 (H55) Seamless Tube is a high-performance copper-nickel (CuNi 90/10) alloy tube widely used in heat exchangers, condensers, desalination plants, and marine cooling systems. DLSS supplies tubes in 35 mm OD × 1.0 mm wall thickness × 1150 mm length, manufactured according to ASTM B111 standards.

All tubes are delivered in H55 temper (hard-drawn) condition for enhanced strength, and undergo 100% Eddy Current Testing (ET) to ensure defect-free supply. In addition, the tubes have successfully passed third-party inspections (SGS, BV, TUV), guaranteeing compliance with international project requirements.

What is ASTM B111 C70600 (H55)?

C70600 (UNS C70600, CuNi 90/10) is a copper-nickel alloy containing:

-

~90% Copper

-

~10% Nickel

-

Small additions of Iron and Manganese

These elements provide:

-

Excellent resistance to seawater corrosion, erosion, and biofouling

-

Good mechanical strength and ductility

-

Proven performance in marine, offshore, and industrial cooling applications

The H55 condition indicates a hard-drawn temper, providing higher strength compared to annealed tubes.

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B111 |

| Material | C70600 (CuNi 90/10) |

| Condition | H55 (Hard-Drawn) |

| Type | Seamless Tube |

| Size | 35 mm OD × 1.0 mm WT × 1150 mm Length |

| Testing | 100% Eddy Current Testing (ET) |

| Inspection | Passed Third-Party Inspection (SGS/BV/TUV) |

| Applications | Heat exchangers, condensers, desalination, marine cooling, power plants |

Key Features

-

Seamless Construction – ensures leak-proof performance under pressure.

-

Superior Corrosion Resistance – CuNi 90/10 alloy resists seawater attack and fouling.

-

H55 Hard-Drawn Condition – provides improved mechanical strength and durability.

-

100% Eddy Current Tested – ensures every tube is defect-free.

-

Third-Party Certified – compliance guaranteed for EPC and end-user projects.

Applications

-

Heat Exchangers & Condensers – for petrochemical, refinery, and power industries.

-

Desalination Plants – brine-resistant CuNi tubes for long service life.

-

Marine Engineering – shipboard cooling, condensers, and seawater systems.

-

Offshore Oil & Gas – subsea and platform cooling applications.

-

Power Plant Cooling Systems – seawater-cooled condensers and tube bundles.

Why Choose DLSS?

-

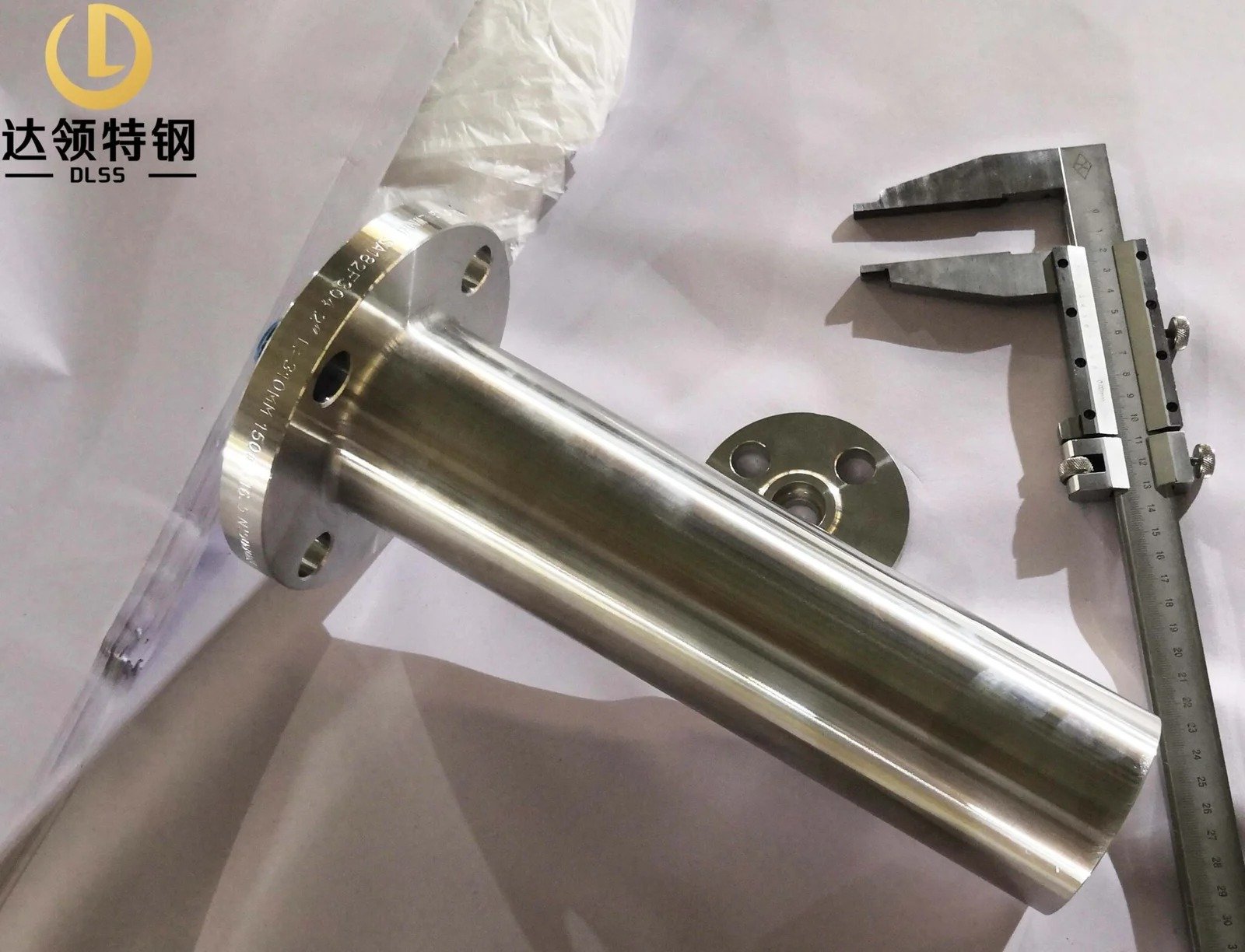

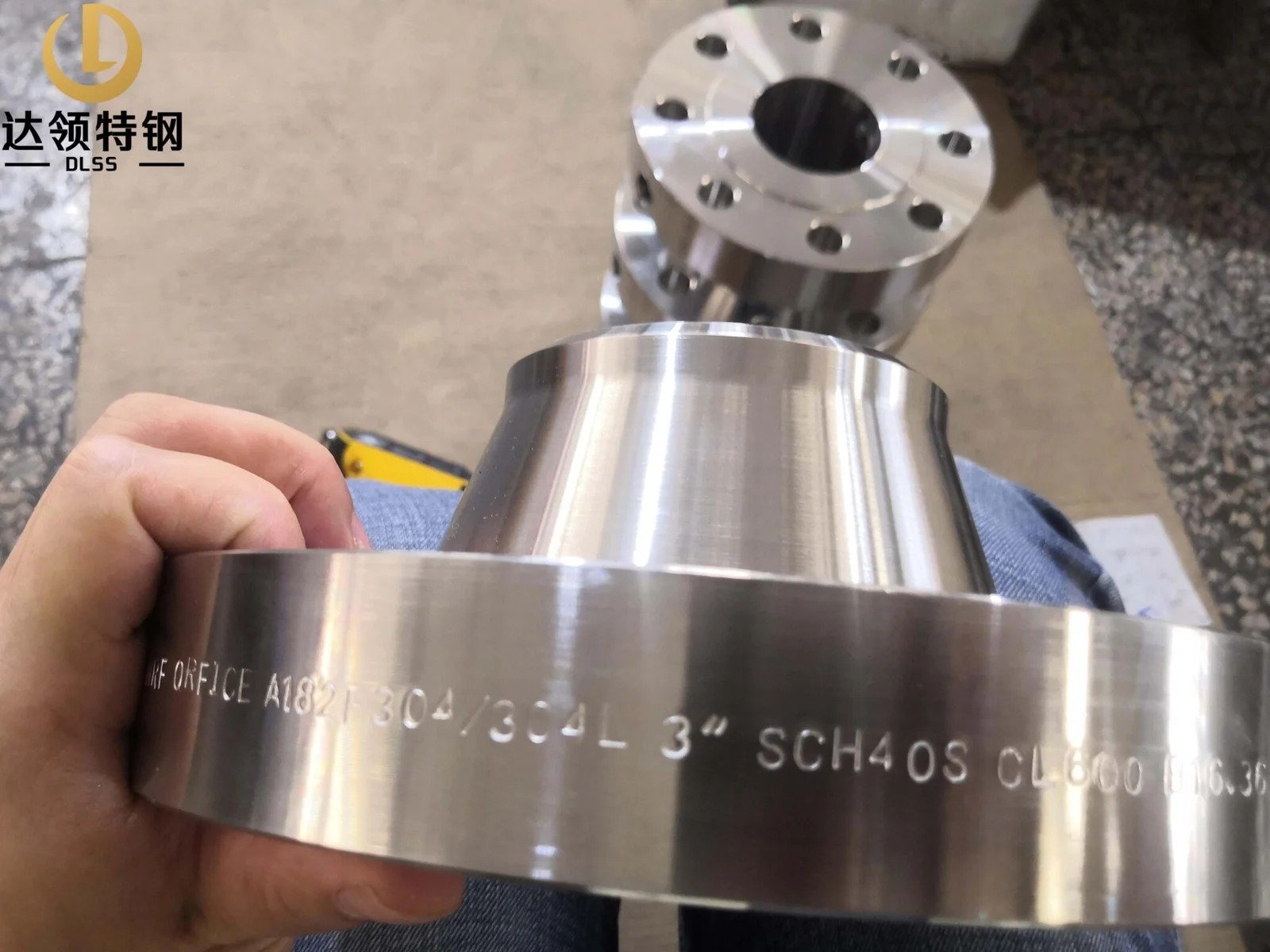

Supply of complete C70600 CuNi tube packages – straight tubes, U-bend, finned tubes.

-

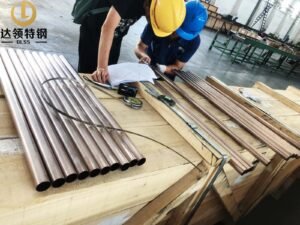

Strict QC – 100% ET, hydrostatic, dimensional, and PMI checks.

-

Certified Quality – EN 10204/3.1 MTC + SGS/BV/TUV third-party inspection.

-

Global Projects – trusted supplier for desalination, marine, and industrial heat exchanger systems.

-

Export Packaging – tubes capped, plastic wrapped, seaworthy wooden cases.

Frequently Asked Questions (FAQ)

Q1: What does H55 mean for C70600 tubes?

A1: H55 indicates a hard-drawn temper, giving higher strength compared to annealed tubes (O61).

Q2: Why use Eddy Current Testing (ET)?

A2: 100% ET detects surface and subsurface defects, ensuring defect-free tubing.

Q3: What third-party inspections are available?

A3: SGS, BV, TUV, or client-nominated agencies can certify the tubes.

Q4: Can DLSS supply U-bend C70600 tubes for heat exchangers?

A4: Yes, we provide straight, U-bend, and finned tubes for complete heat exchanger solutions.