Introduction

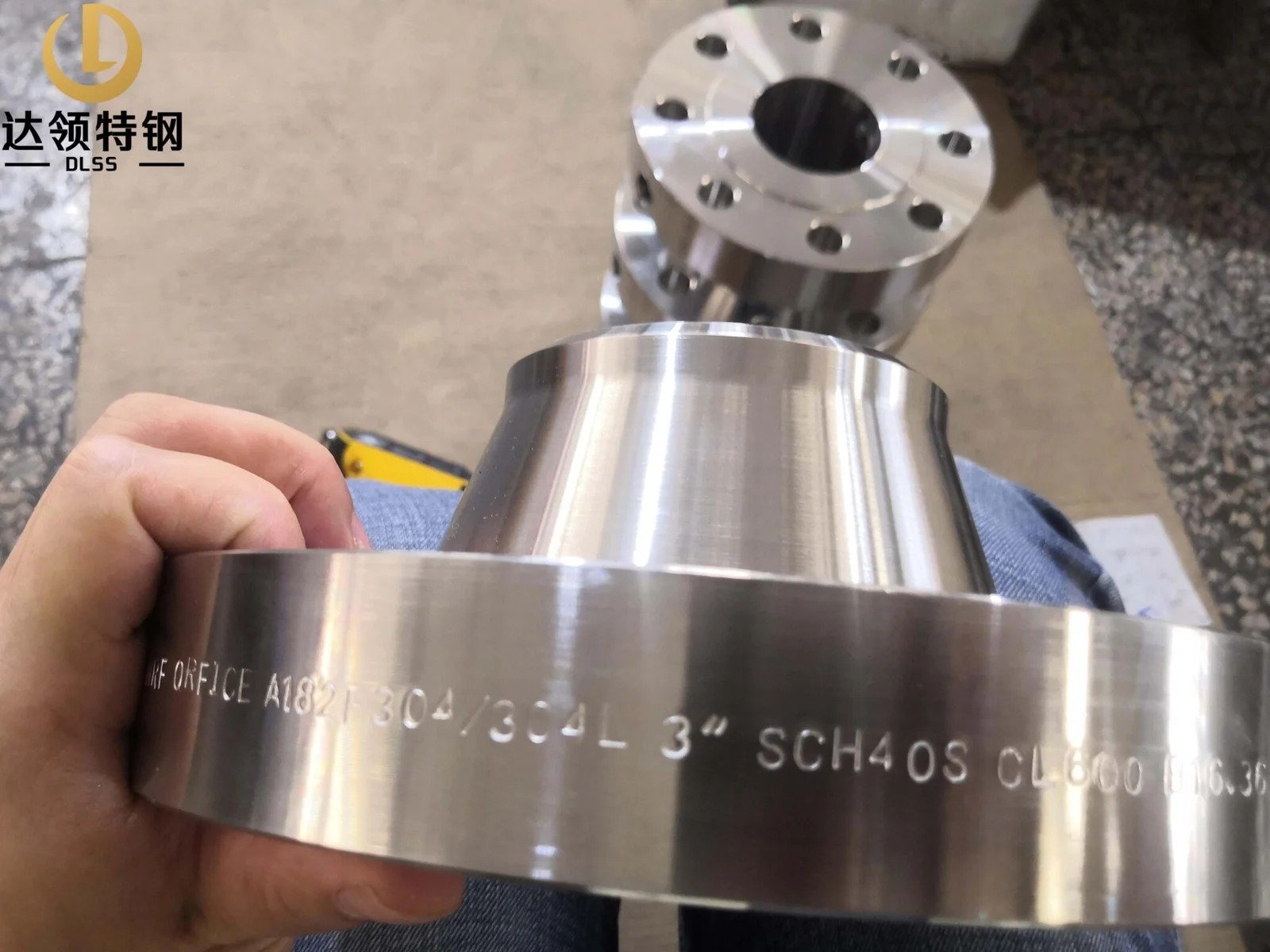

ASTM B151 C70600 Forged Elbow is a high-performance fitting designed for high-pressure marine and industrial piping systems. Manufactured according to ASME B16.11, these forged elbows are supplied with NPT threaded connections and a 3000# pressure rating, ensuring reliable strength and leak-proof performance.

The material C70600 (CuNi 90/10), a copper-nickel alloy with approximately 90% copper and 10% nickel plus small additions of iron and manganese, is highly valued for its outstanding resistance to seawater corrosion, erosion, and biofouling. This makes C70600 forged elbows the preferred choice in marine engineering, offshore oil & gas, desalination plants, and petrochemical industries.

What is C70600 Copper-Nickel?

C70600 (UNS C70600, CuNi 90/10) is a copper-nickel alloy known for:

-

Excellent seawater corrosion resistance – performs well in both clean and brackish waters.

-

Resistance to erosion and impingement attack – reliable under high-flow conditions.

-

Biofouling resistance – reduces marine organism growth on internal surfaces.

-

Good mechanical properties – strength combined with ductility for high-pressure applications.

Because of these characteristics, ASTM B151 C70600 forged elbows are widely used in condenser systems, seawater cooling lines, and industrial pipelines.

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B151 / ASME B16.11 |

| Material | C70600 (CuNi 90/10) |

| Type | Forged Elbow, NPT Threaded |

| Pressure Class | 3000# |

| Connection | NPT (National Pipe Thread) |

| Size Range | 1/2″ to 4″ (custom sizes available) |

| Corrosion Resistance | Excellent in seawater, brackish water, and chloride-rich environments |

| Applications | Marine piping, condensers, petrochemical, offshore oil & gas |

Key Features

-

High-Pressure Performance – Forged construction, rated 3000#, ensures safety and reliability.

-

Superior Corrosion Resistance – CuNi 90/10 alloy resists seawater attack, scaling, and fouling.

-

Easy Installation – NPT threaded ends allow fast assembly with leak-proof sealing.

-

Standards Compliance – Produced according to ASTM B151 and ASME B16.11 for interchangeability.

-

Durable Service Life – Long-lasting in aggressive marine and chemical environments.

Applications

-

Marine & Offshore Piping Systems – seawater cooling, ballast systems, and engine cooling.

-

Desalination Plants – corrosion-resistant fittings for brine and seawater service.

-

Power Plant Condensers – reliable elbows for seawater cooling systems.

-

Oil & Gas Platforms – offshore piping requiring high-pressure, anti-corrosion fittings.

-

Chemical & Petrochemical Industry – handling corrosive fluids in harsh environments.

Why Choose DLSS for C70600 Forged Elbows?

-

Strict Quality Control – Every fitting inspected for dimensional accuracy and surface integrity.

-

Certified Manufacturing – ASTM B151 and ASME B16.11 compliance with MTC (EN 10204/3.1).

-

Global Supply Experience – Trusted by clients in 40+ countries.

-

Custom Options – Available in elbows, tees, couplings, and reducers in CuNi alloys.

-

Seaworthy Packaging – Export wooden cases, ISPM-15 certified, safe for international transport.

Frequently Asked Questions (FAQ)

Q1: Why choose C70600 copper-nickel for elbows?

A1: It provides excellent resistance to seawater corrosion, erosion, and biofouling, ensuring long service life in marine and industrial systems.

Q2: What does 3000# mean?

A2: It refers to the pressure rating (Class 3000), indicating suitability for high-pressure service conditions.

Q3: Are NPT threads the only option?

A3: Standard supply is NPT, but other threaded types can be produced upon request.

Q4: Can DLSS provide third-party inspections?

A4: Yes, inspections by SGS, BV, or TUV can be arranged according to customer requirements.