Introduction

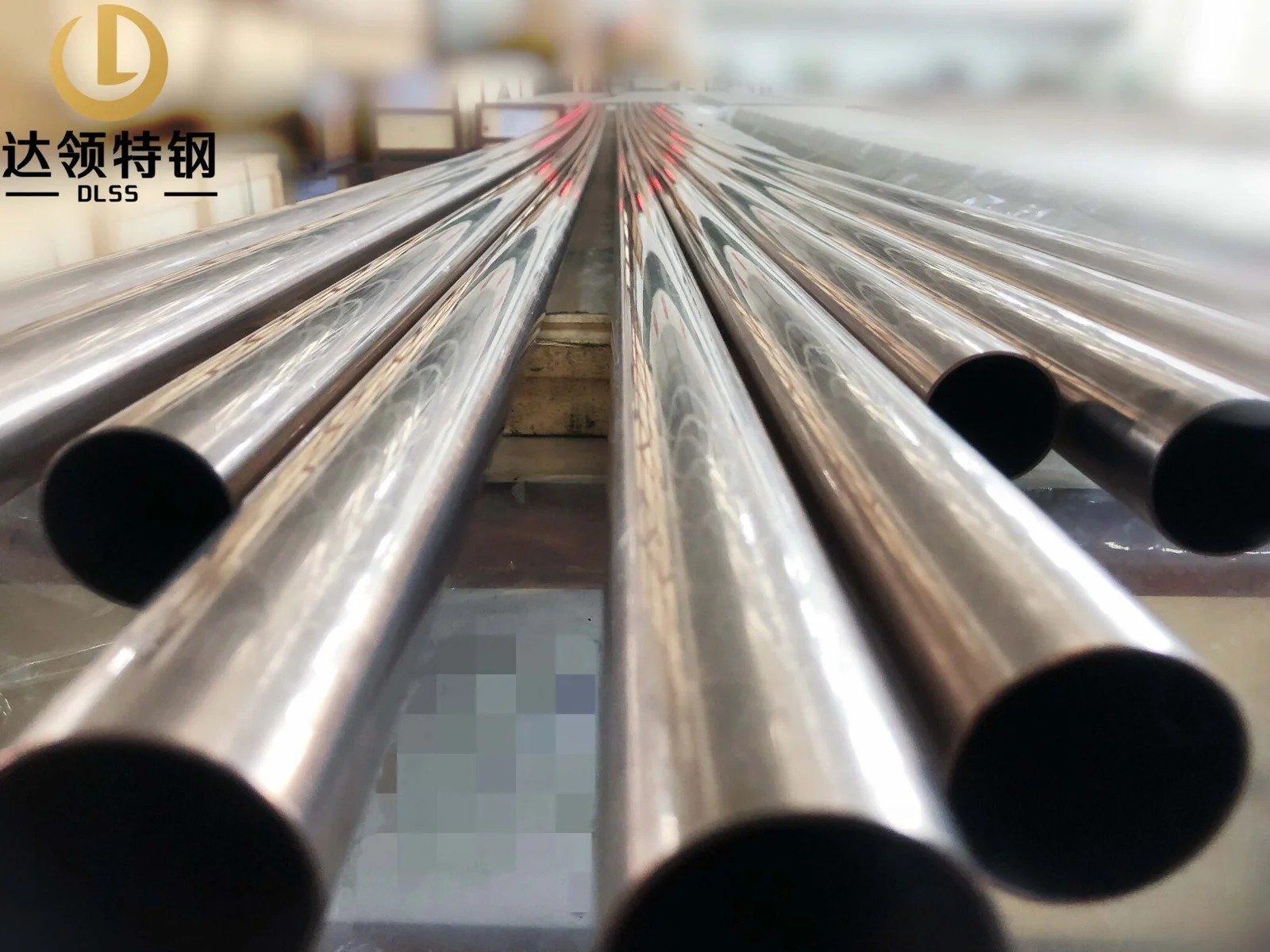

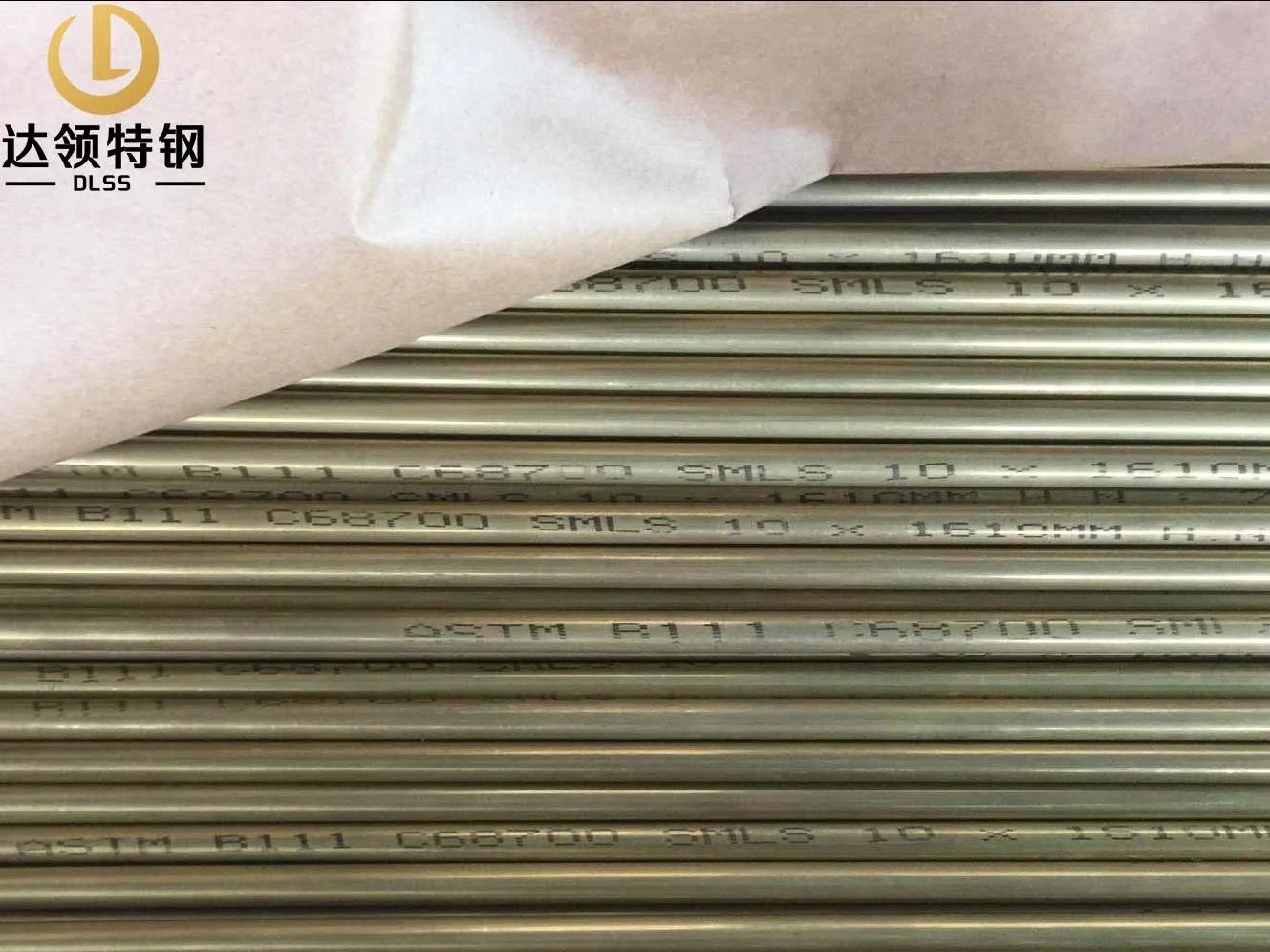

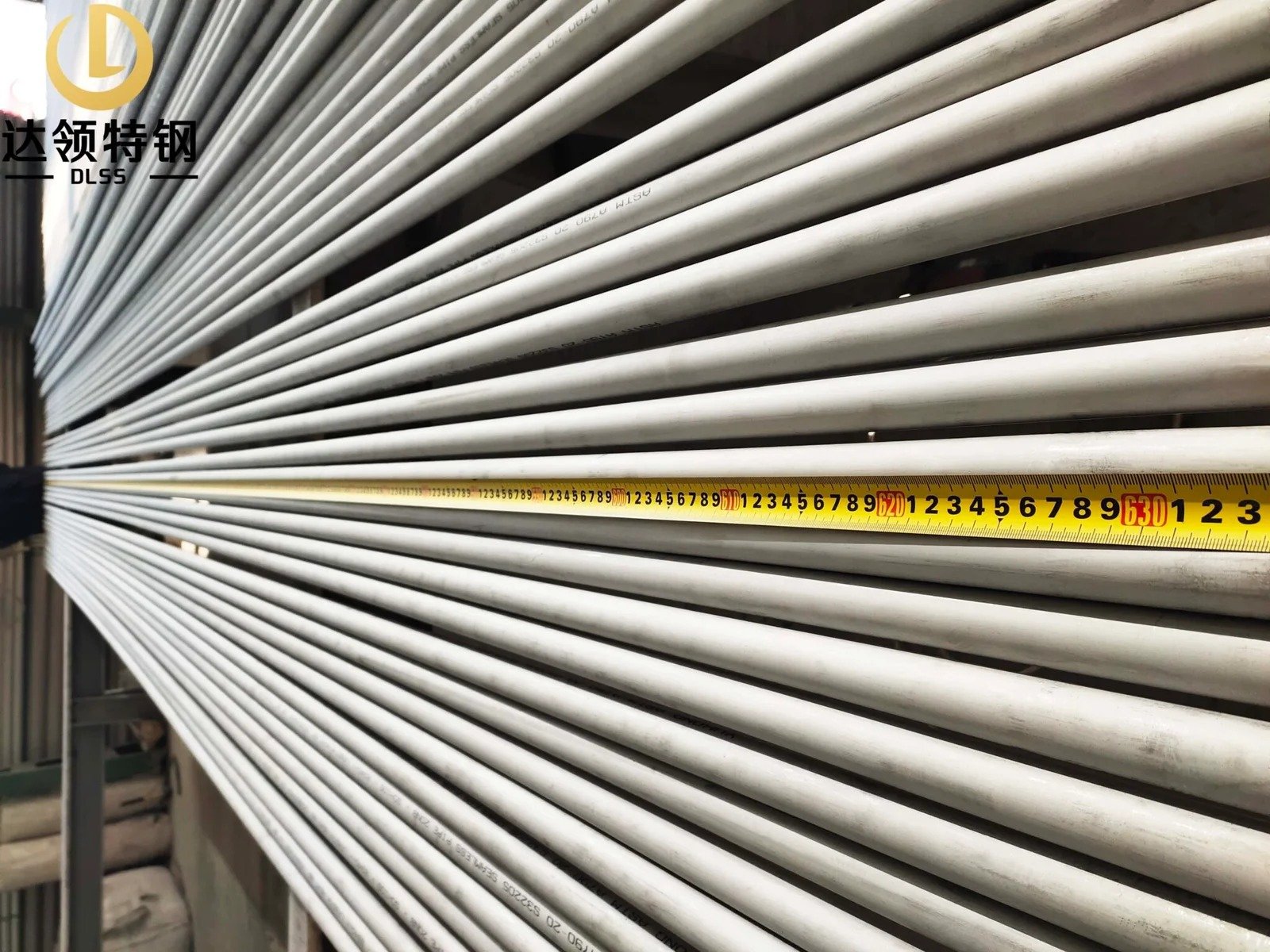

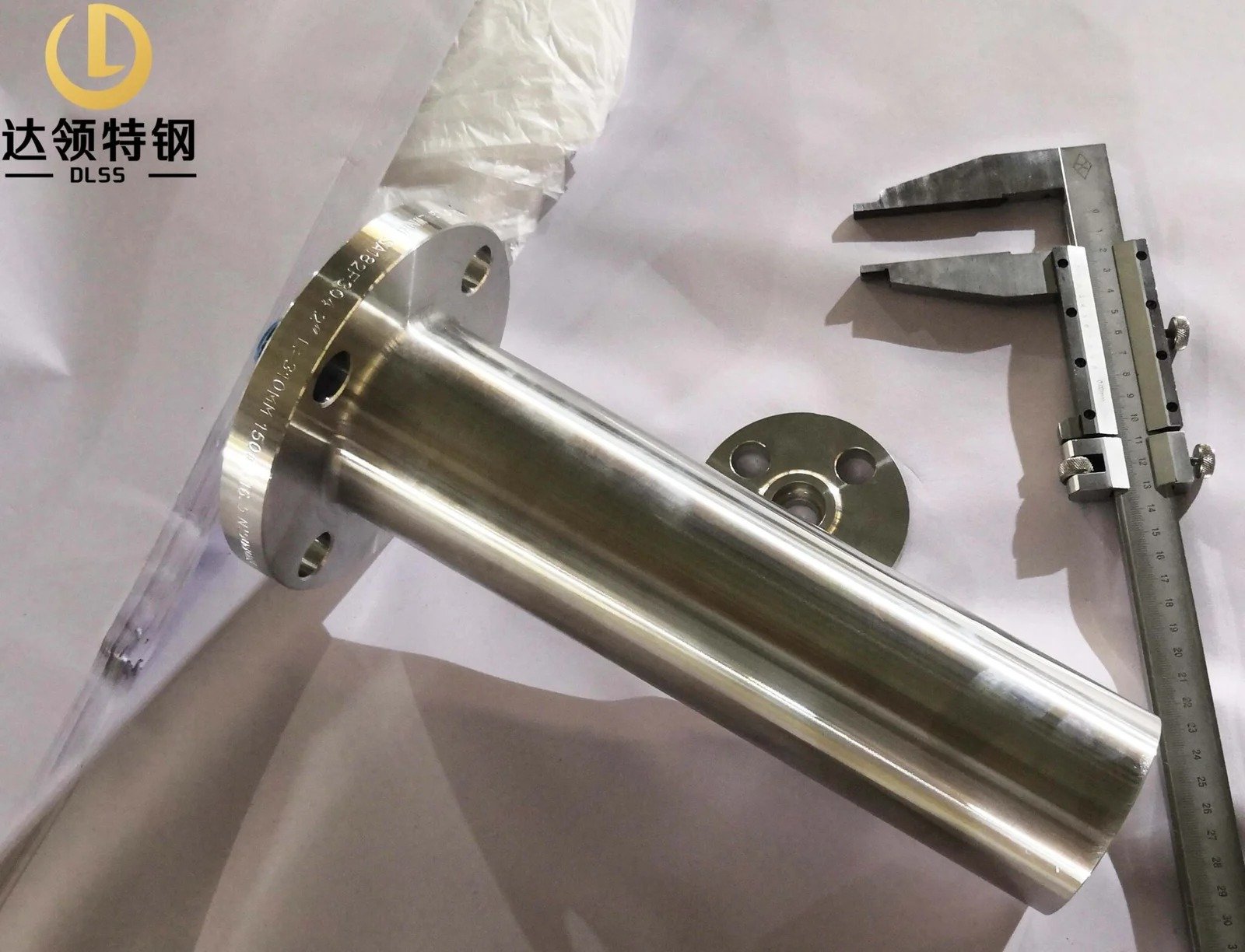

ASTM B163 Incoloy 825 Seamless Tube (UNS N08825) is a high-performance nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. DLSS supplies seamless tubes in size 25.4 mm OD × 2.11 mm WT × 5555 mm length, manufactured according to ASTM B163 and finished with a bright annealed surface for enhanced smoothness, corrosion resistance, and cleanliness.

Incoloy 825 is renowned for its excellent resistance to corrosive environments, especially sulfuric acid, phosphoric acid, seawater, and chloride-containing media, making it a preferred choice for heat exchangers, condensers, chemical processing, and marine applications.

What is Incoloy 825 (UNS N08825)?

Incoloy 825 is a nickel-iron-chromium alloy with additions of:

-

Nickel (38–46%)

-

Iron (22% min.)

-

Chromium (19.5–23.5%)

-

Molybdenum, Copper, and Titanium

Key advantages:

-

Excellent resistance to oxidizing and reducing acids

-

High resistance to stress-corrosion cracking

-

Strong resistance to pitting and crevice corrosion in seawater

-

Good mechanical properties at both room and elevated temperatures

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B163 |

| Material | Incoloy 825 (UNS N08825) |

| Type | Seamless Tube |

| Size | 25.4 mm OD × 2.11 mm WT × 5555 mm Length |

| Surface Finish | Bright Annealed |

| Applications | Heat exchangers, condensers, chemical plants, marine & offshore systems |

Key Features

-

Bright Annealed Finish – smooth inner surface for improved corrosion resistance and cleanliness.

-

Corrosion Resistance – withstands sulfuric acid, phosphoric acid, seawater, and chloride environments.

-

High Strength & Durability – reliable performance under high pressure and temperature.

-

Stress-Corrosion Resistance – minimizes risk of cracking in harsh chemical media.

-

Proven Alloy – widely used in chemical, marine, and oil & gas industries.

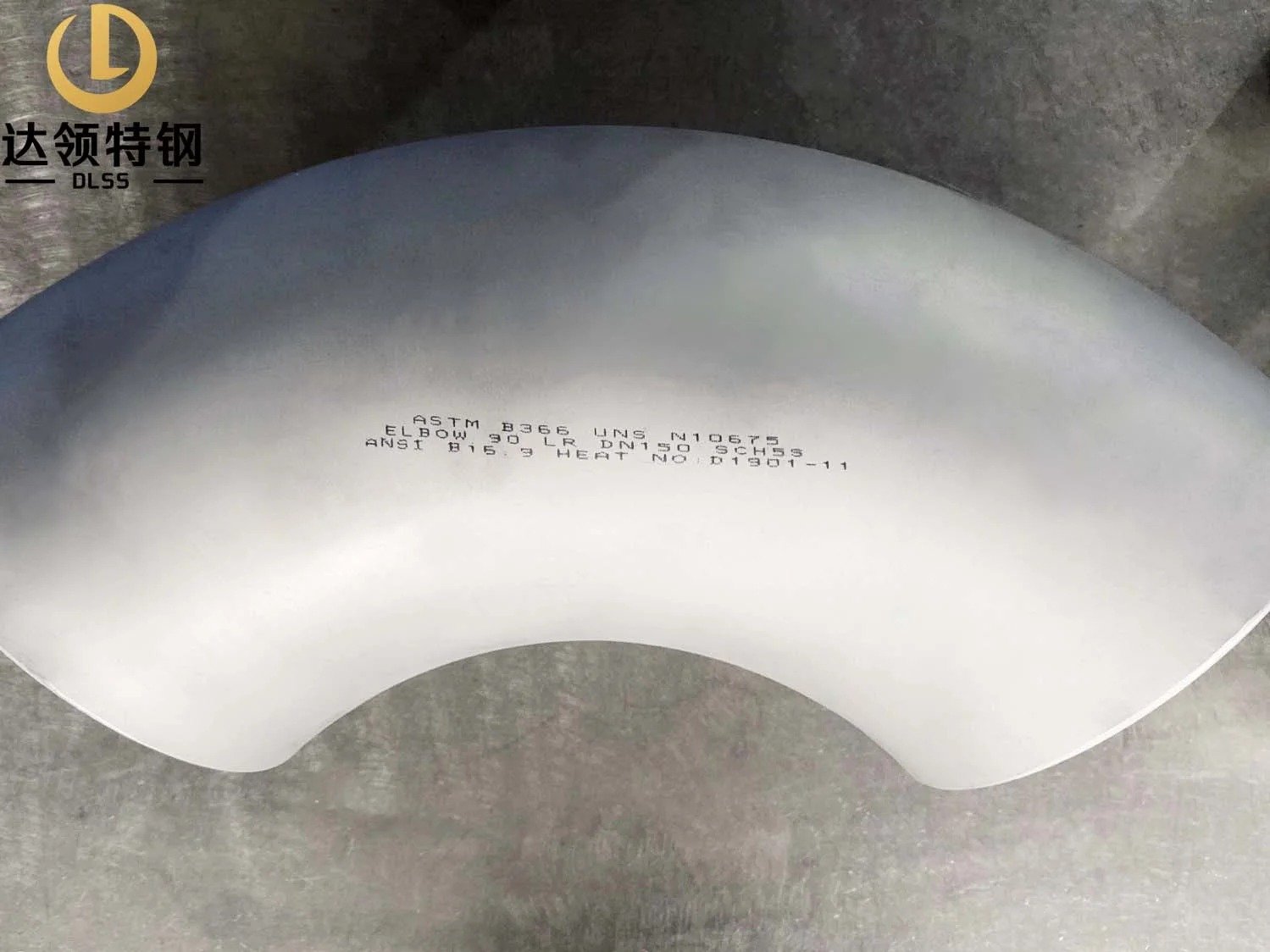

Applications

-

Heat Exchangers & Condensers – for corrosive chemical and marine service.

-

Chemical Processing – sulfuric and phosphoric acid plants.

-

Desalination & Seawater Cooling – resistant to chloride attack.

-

Oil & Gas Industry – offshore platforms, refineries, and piping systems.

-

Power Generation – condensers and high-temperature tube systems.

Why Choose DLSS?

-

Reliable supplier of nickel alloy seamless tubes (Incoloy, Inconel, Hastelloy, Monel).

-

Strict QC – 100% Eddy Current, Hydrostatic, and PMI testing.

-

Third-Party Inspection – SGS, BV, TUV certification available.

-

Export Packaging – capped ends, plastic wrapping, seaworthy wooden cases.

-

Global Projects – supplied to chemical plants, desalination, and offshore systems.

Frequently Asked Questions (FAQ)

Q1: Why use Incoloy 825 for heat exchangers?

A1: Because it resists a wide range of aggressive media, including acids, seawater, and chlorides, ensuring long-term durability.

Q2: What is the benefit of Bright Annealed tubes?

A2: Bright annealing produces a clean, smooth, and oxide-free surface, reducing corrosion initiation points and improving heat transfer efficiency.

Q3: Can DLSS provide other nickel alloy grades?

A3: Yes, DLSS also supplies Inconel 600/625, Monel 400, Hastelloy C-22/C-276, etc.

Q4: What certifications are provided?

A4: MTC EN 10204/3.1, with optional third-party inspection by SGS, BV, or TUV.