Introduction

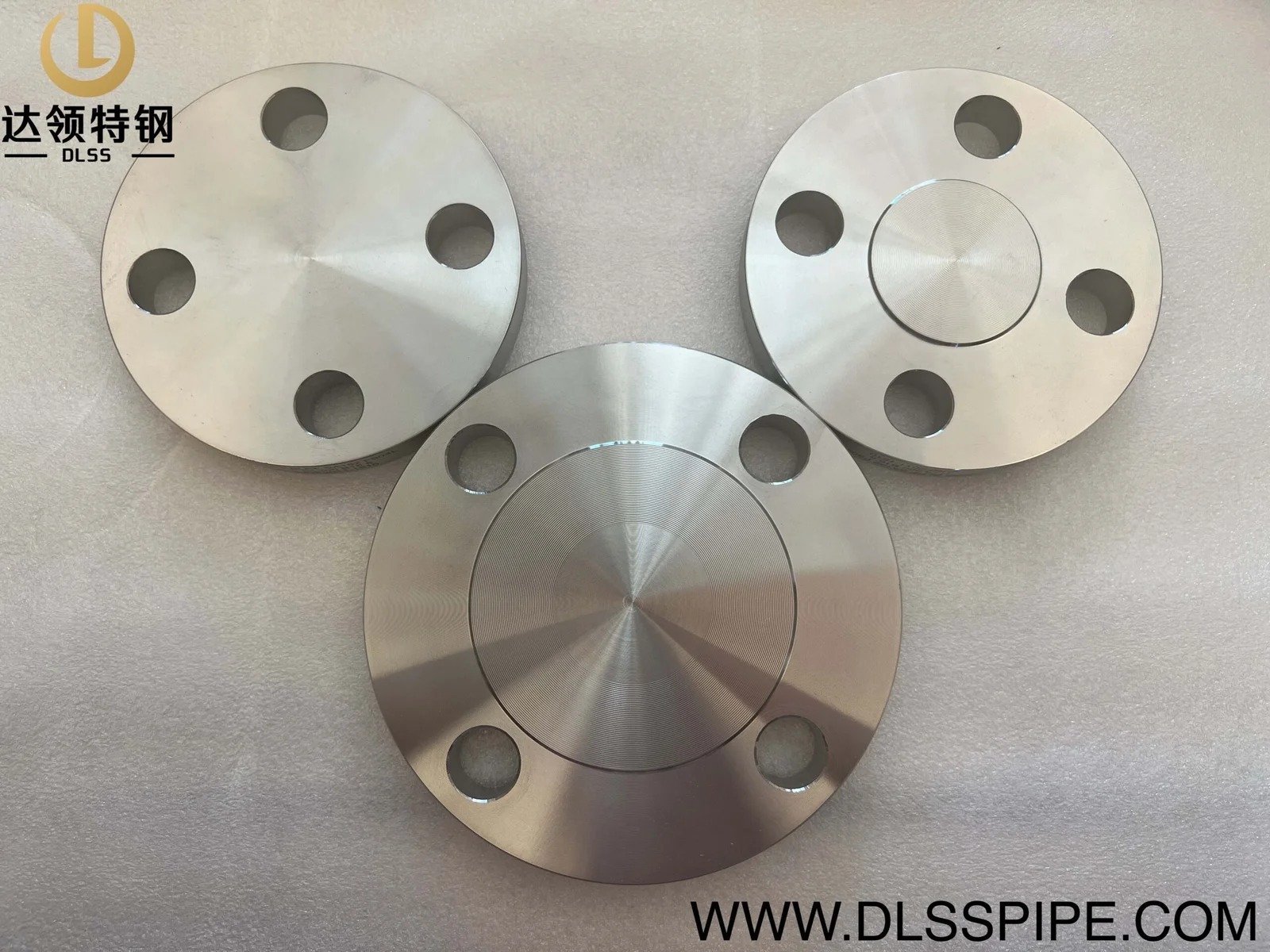

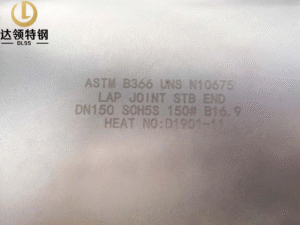

ASTM B366 Hastelloy B-3 Lap Joint Stub End (UNS N10675) is a nickel-molybdenum alloy pipe fitting specifically engineered for highly aggressive reducing chemical environments, such as hydrochloric acid, sulfuric acid, phosphoric acid, and acetic acid.

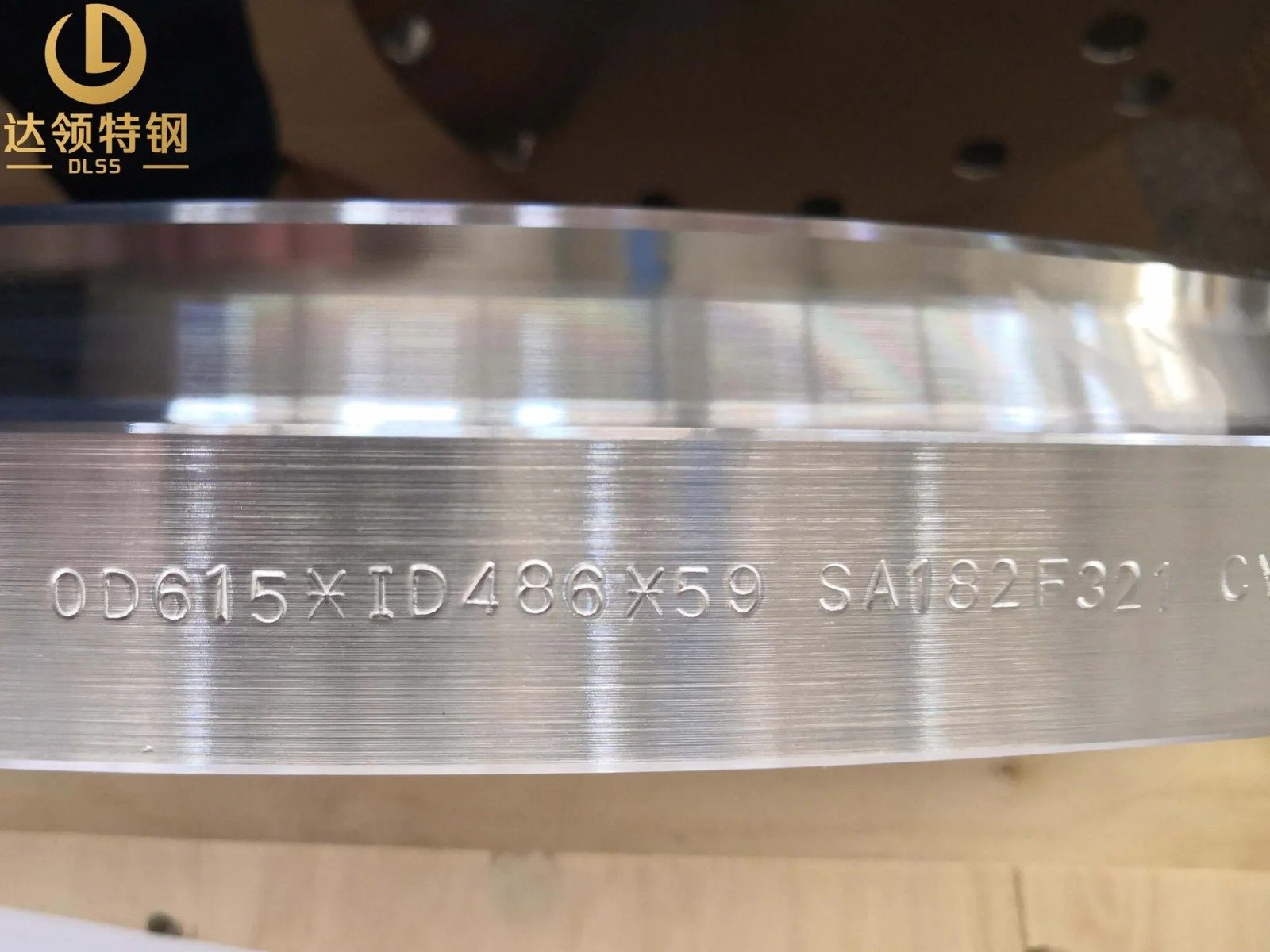

DLSS supplies DN150 SCH5S Stub Ends manufactured to ASTM B366 and dimensionally in compliance with ASME B16.9. As a lap joint stub end, it is designed to be used with a lap joint flange, allowing the flange to be made from carbon steel while only the stub end is produced from expensive Hastelloy alloy—providing significant cost savings.

What is Hastelloy B-3 (UNS N10675)?

Hastelloy B-3 is a nickel-molybdenum alloy developed for resistance to strong reducing acids.

Chemical Composition (Typical)

-

Nickel (Ni): balance

-

Molybdenum (Mo): ~28%

-

Iron (Fe): ≤3%

-

Very low carbon, silicon, and other impurities

Key Benefits

-

Excellent resistance to hydrochloric acid across all concentrations and temperatures

-

Good resistance to sulfuric, phosphoric, and acetic acids

-

Improved thermal stability compared with Hastelloy B-2, minimizing fabrication problems

-

Resistant to pitting and stress corrosion cracking in reducing conditions

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B366 |

| Material | Hastelloy B-3 (UNS N10675) |

| Fitting Type | Lap Joint Stub End |

| Size | DN150 (6 inch) |

| Schedule | SCH5S |

| Dimension Standard | ASME B16.9 |

| Surface Finish | As manufactured / Pickled / Machined |

| Applications | Acid service piping, chemical plants, heat exchangers, refinery systems |

Key Features of ASTM B366 Hastelloy B-3 Stub End

-

Lap Joint Design – reduces total alloy consumption by using backing flanges.

-

Superior Acid Resistance – withstands hydrochloric, sulfuric, and phosphoric acids.

-

Thermal Stability – enhanced fabrication performance over earlier B-series alloys.

-

Durability – reliable in continuous severe chemical service.

-

Compliance – meets ASTM B366 and ASME B16.9 requirements.

Applications

-

Chemical Processing Equipment – piping systems for hydrochloric and sulfuric acids.

-

Refineries & Petrochemical Plants – reactors, scrubbers, and acid service units.

-

Heat Exchangers – connections exposed to aggressive reducing media.

-

Pharmaceutical Industry – equipment requiring acid resistance and stability.

-

Waste Treatment & Acid Regeneration – durable in chloride-rich conditions.

Hastelloy B-3 vs Hastelloy C276 – Comparison

| Item / Alloy | Hastelloy B-3 (UNS N10675) | Hastelloy C276 (UNS N10276) |

|---|---|---|

| Standard | ASTM B366 / B622 / B335 | ASTM B366 / B622 / B575 |

| Main Composition | Ni (balance), Mo ~28%, Fe ≤3%, very low C & Si | Ni (balance), Cr 15–17%, Mo 15–17%, W ~3.5%, Fe 4–7% |

| Corrosion Resistance | Excellent in reducing acids (HCl, H₂SO₄, H₃PO₄, acetic acid) | Superior in both oxidizing & reducing media, incl. strong chlorides and seawater |

| Pitting / Crevice Resistance | Moderate – excellent in reducing acids but less effective in oxidizers | Excellent – handles aggressive chlorides and oxidizers |

| Stress Corrosion Cracking | Good in reducing chloride conditions | Outstanding in a wide range of chloride-rich environments |

| Thermal Stability | Improved vs. B-2, stable during fabrication and welding | Excellent – suitable for ambient and high-temp service |

| Temperature Range | Effective up to ~425–450°C (reducing acids) | Effective up to ~1250°C |

| Cost Level | Medium | Higher |

| Typical Applications | – Hydrochloric acid plants – Sulfuric acid reactors – Acid pickling lines |

– Flue gas scrubbers – Marine piping – Chemical reactors – Waste treatment – Desalination |

| Summary | Best for highly reducing acid service | Best for mixed oxidizing + reducing conditions |

Professional Summary

-

Hastelloy B-3 is the best choice when service involves hydrochloric or sulfuric acids under strongly reducing conditions.

-

Hastelloy C276 is more versatile, suitable for both oxidizing and reducing environments, including seawater and mixed acid service.

If your system is primarily hydrochloric acid service, choose B-3.

If your process includes oxidizers, chlorides, or uncertain environments, choose C276.

Why Choose DLSS?

-

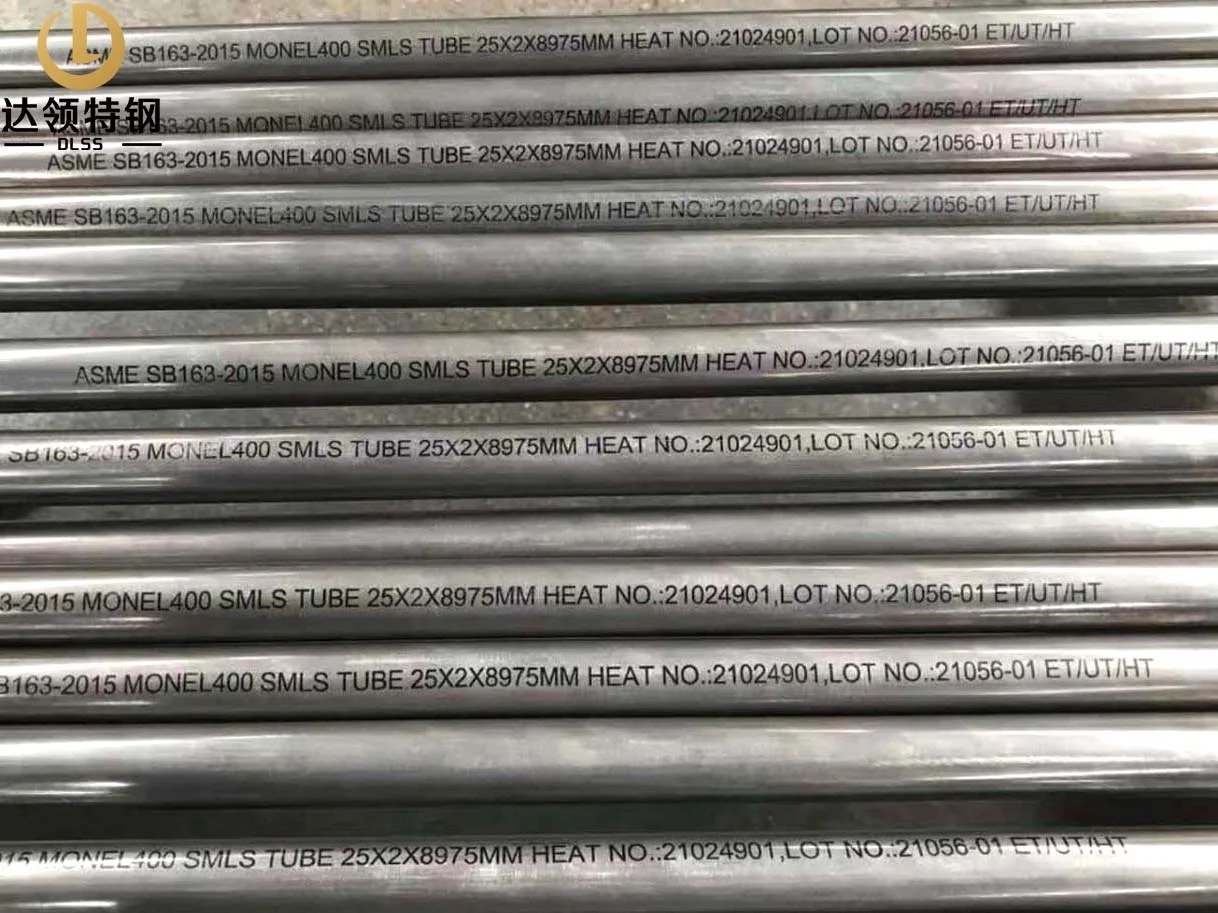

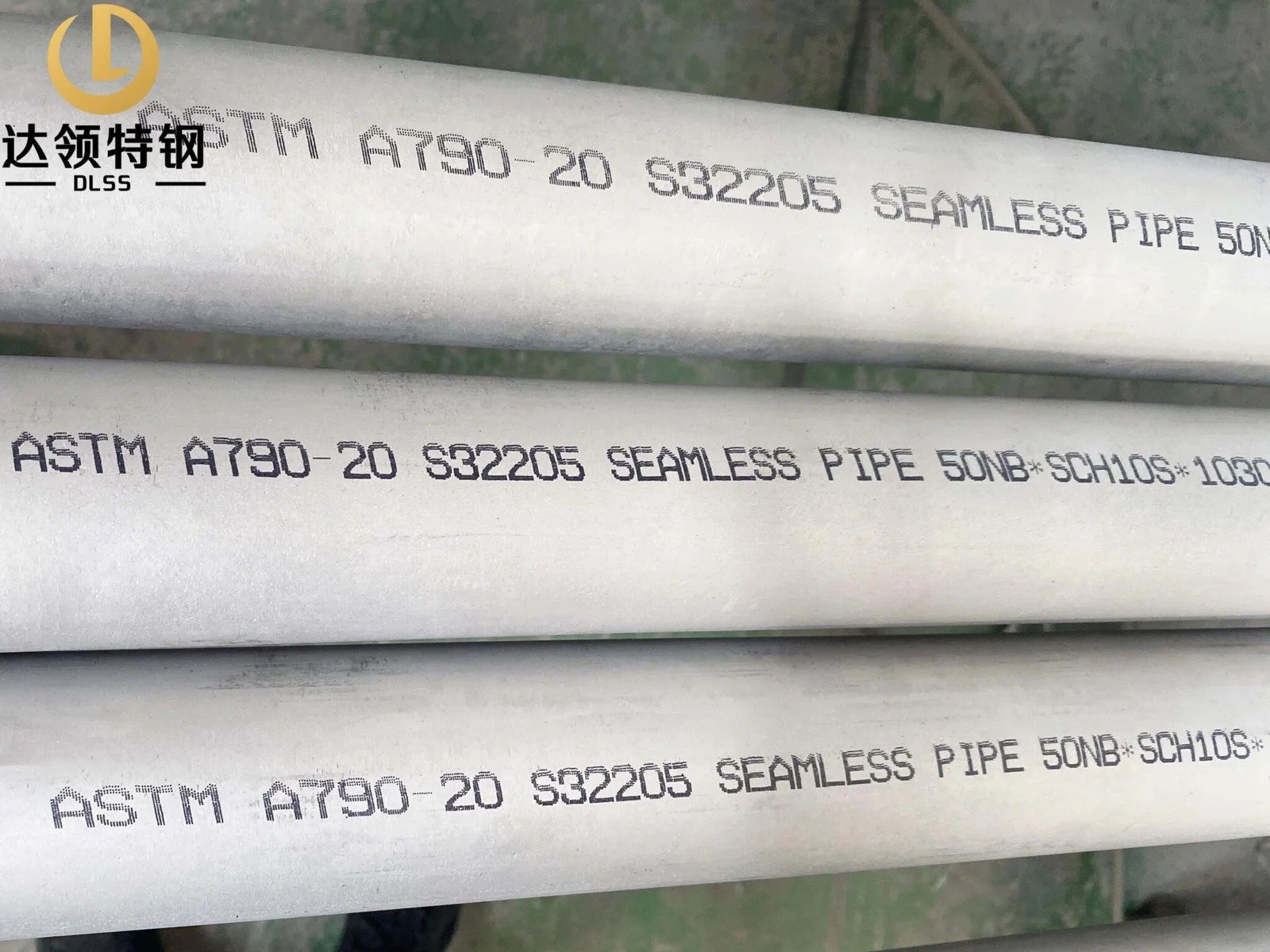

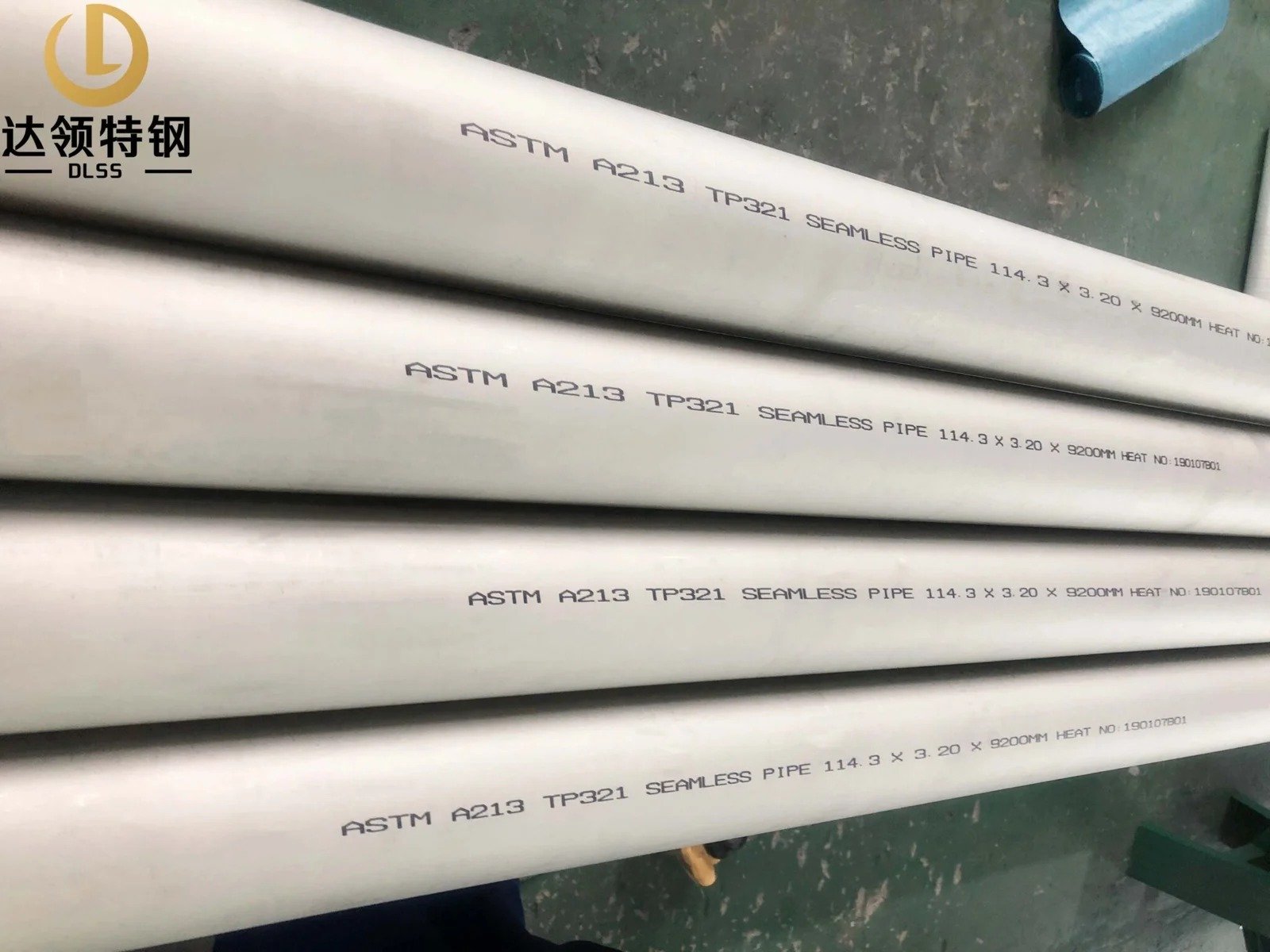

Wide supply range of nickel alloy fittings: Hastelloy B-3, C22, C276, Inconel, Monel, Alloy 20.

-

Strict Quality Control – PMI, UT, ET, Hydro, and dimensional inspection.

-

Third-Party Certification – SGS, BV, TUV available.

-

Seaworthy Packaging – ISPM-15 wooden cases, plastic protection, capped ends.

-

Proven Track Record – supplied to acid plants, refineries, and EPC projects worldwide.