Introduction

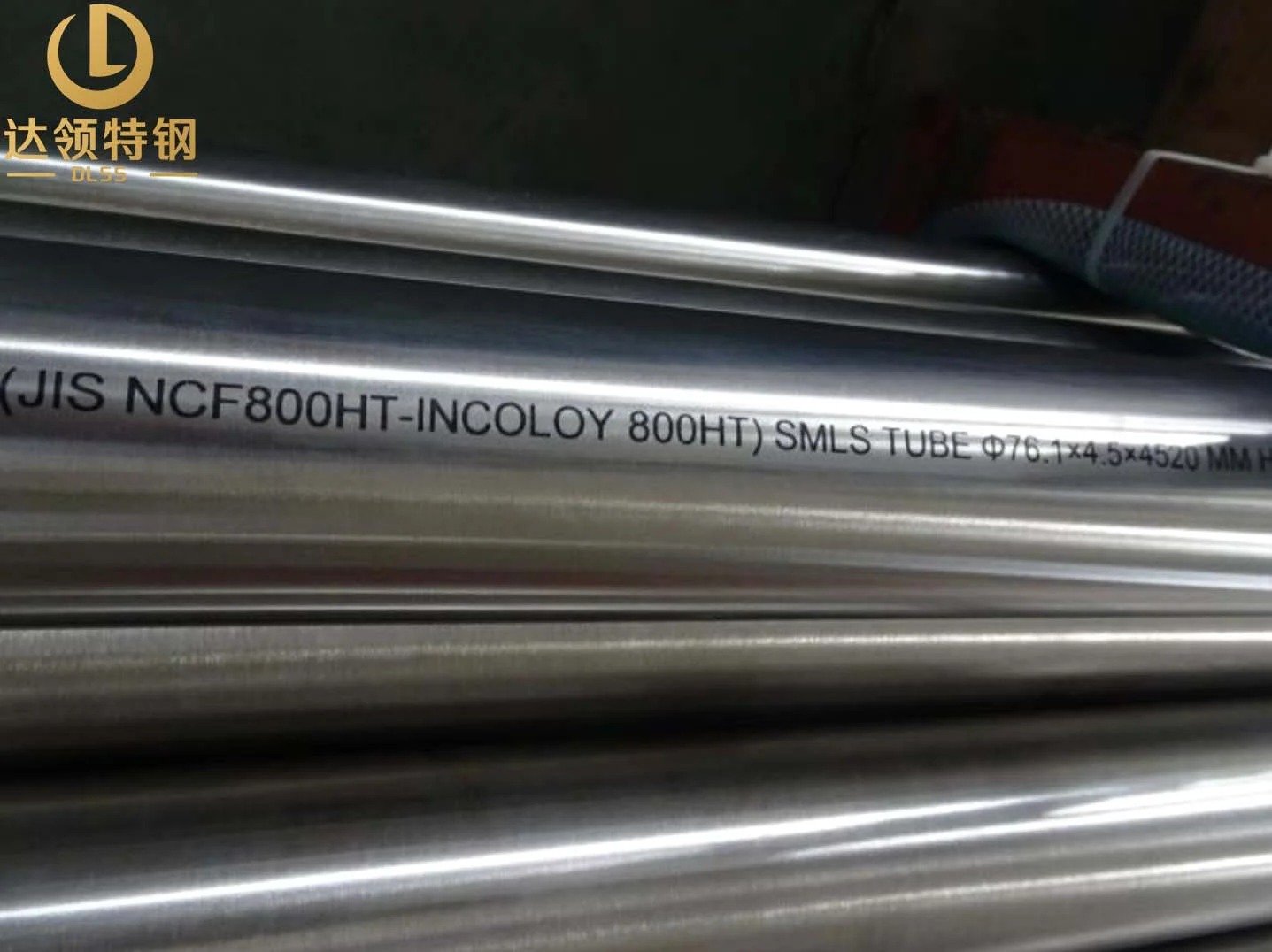

ASTM B407 Alloy 800H Seamless Pipe (UNS N08810) is a high-temperature nickel-iron-chromium alloy pipe designed for applications requiring excellent strength, oxidation resistance, and carburization resistance. DLSS supplies seamless pipes in size 50.8 mm OD × 5.16 mm WT × 6096 mm length (20FT), manufactured according to ASTM B407.

All pipes are subjected to 100% Eddy Current Testing (ET) to ensure freedom from surface and subsurface defects, making them suitable for critical service in heat exchangers, reformers, boilers, and petrochemical processing units.

What is Alloy 800H (UNS N08810)?

Alloy 800H is a modification of Incoloy 800 with higher creep and rupture strength. Its composition includes:

-

Nickel (30–35%)

-

Chromium (19–23%)

-

Iron (balance)

-

Carbon (0.05–0.10%) for improved high-temperature strength

Key advantages of ASTM B407 Alloy 800H Seamless Pipe:

-

Excellent resistance to oxidation and carburization at high temperatures

-

Improved creep strength compared to standard Incoloy 800

-

Good structural stability under long-term exposure above 600°C

-

Proven performance in heat exchangers, furnace tubes, and petrochemical systems

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B407 |

| Material | Alloy 800H (Incoloy 800H, UNS N08810) |

| Type | Seamless Pipe |

| Size | 50.8 mm OD × 5.16 mm WT × 6096 mm Length (20FT) |

| Surface Finish | As manufactured / Bright or Pickled on request |

| Testing | 100% Eddy Current Testing (ET) |

| Applications | Heat exchangers, reformer tubes, boilers, petrochemical plants, power generation |

Key Features of ASTM B407 Alloy 800H Seamless Pipe

-

Seamless Construction – high reliability under pressure and thermal cycling.

-

High-Temperature Strength – retains mechanical properties above 600°C.

-

Creep & Rupture Resistance – designed for long-term elevated temperature service.

-

100% Eddy Current Tested – ensures defect-free quality for critical applications.

-

Corrosion Resistance – resists oxidation, carburization, and nitric acid environments.

Applications

-

Heat Exchangers – operating at high temperature with oxidizing/corrosive gases.

-

Petrochemical Industry – furnace tubes, ethylene crackers, hydrogen reformers.

-

Power Generation – superheater and reheater tubes in boiler systems.

-

Thermal Processing Equipment – kilns, heat-treatment fixtures, and radiant tubes.

-

Chemical Plants – nitric acid, sulfur compounds, and oxidation-resistant piping.

Why Choose DLSS?

-

Expertise in nickel alloy seamless pipes – Alloy 800H, 800HT, Incoloy 825, Inconel 625.

-

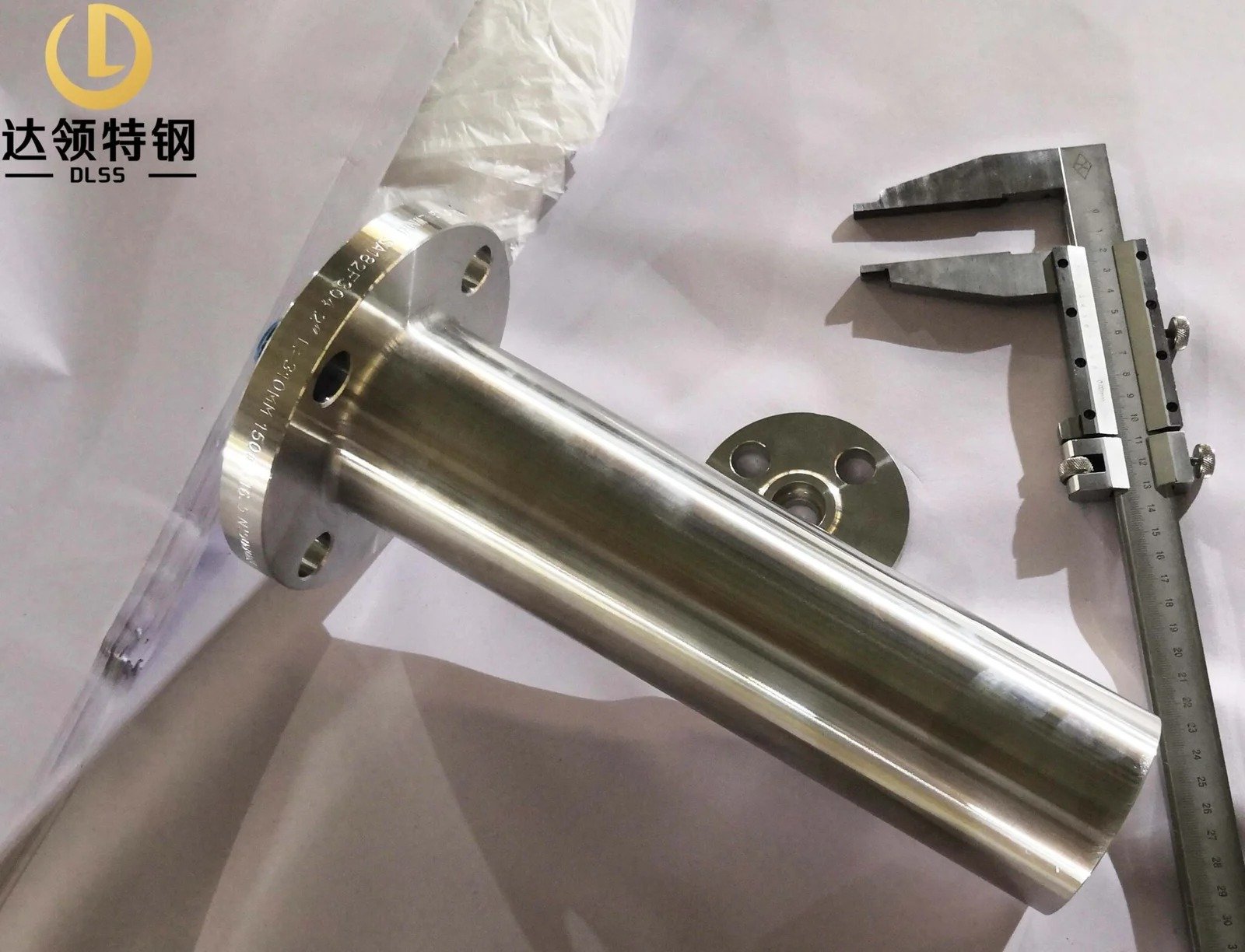

Strict Testing – 100% Eddy Current + Hydrostatic, UT, and PMI as required.

-

Third-Party Inspection – SGS, BV, TUV available.

-

Export Packaging – plastic caps, seaworthy wrapping, ISPM-15 wooden cases.

-

Global Supply – delivered to refineries, power plants, and chemical projects worldwide.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between Alloy 800H and 800HT?

A1: Both have similar compositions, but 800HT has tighter control on carbon, Al, and Ti content, offering even better creep resistance.

Q2: Why use Eddy Current Testing (ET)?

A2: ET detects cracks and defects near the surface, ensuring reliable performance in high-temperature service.

Q3: Can DLSS supply Alloy 800H in custom lengths?

A3: Yes, besides 20FT, we can supply cut-to-length or U-bend tubes for exchangers.

Q4: Which industries most commonly use Alloy 800H seamless pipes?

A4: Petrochemical, power generation, chemical processing, and thermal engineering.