Product Description

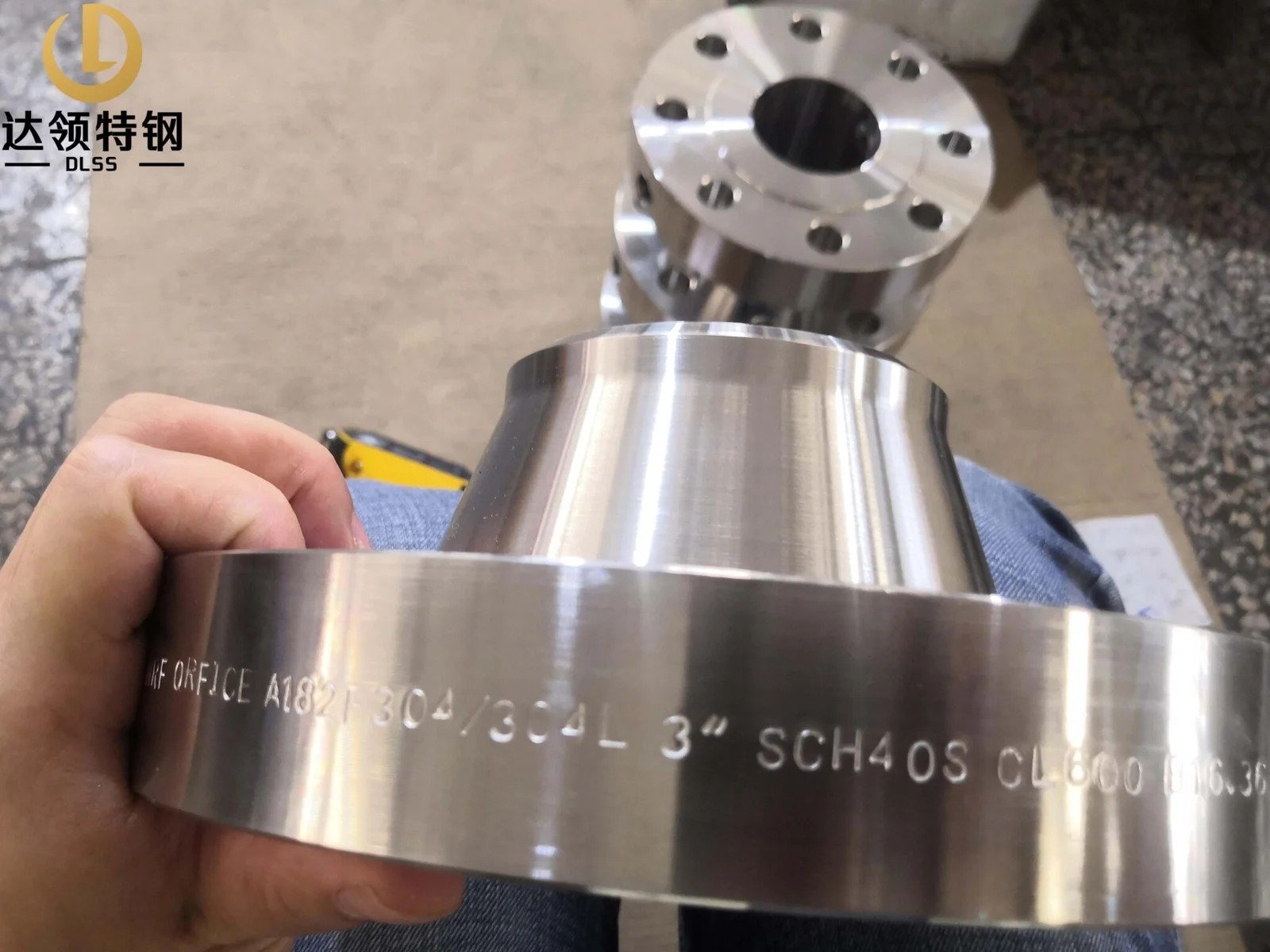

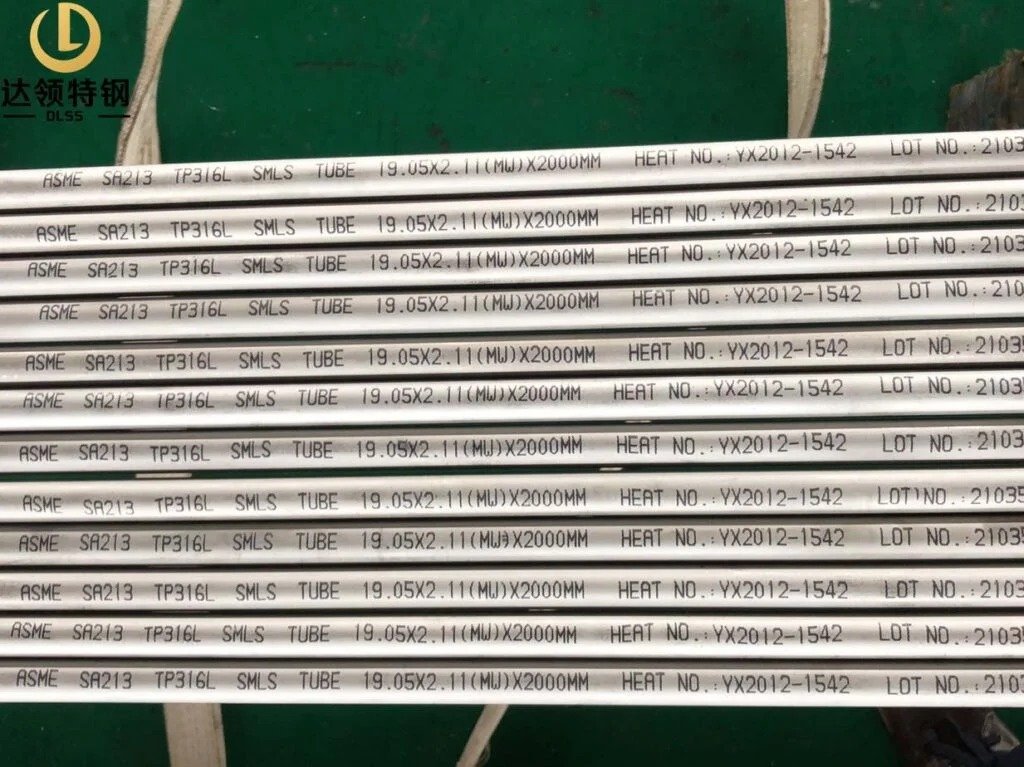

DLSS supplies ASTM B466 C70600 Seamless Eccentric Reducers (ECC Reducer) in size 6″ × 3″, schedule SCH80, manufactured to ASME B16.9. The material C70600 (CuNi 90/10) provides excellent seawater corrosion resistance, erosion resistance, and biofouling resistance, making it the ideal choice for marine, desalination, power generation, and offshore oil & gas industries.

This reducer is supplied together with C70600 seamless pipes and matching flanges, ensuring full system compatibility and consistent material performance.

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B466 / ASME B16.9 |

| Material | C70600 (Copper-Nickel 90/10) |

| Type | Seamless Eccentric Reducer (SMLS ECC) |

| Size | 6″ × 3″ |

| Thickness | SCH80 |

| Connection | Butt-Weld |

| Package | Supplied together with C70600 Seamless Pipes and Flanges |

| Applications | Marine piping, condensers, seawater cooling, desalination, offshore oil |

Key Features

-

Seamless Construction – High strength, smooth flow transition, and leak-proof performance.

-

Superior Corrosion Resistance – CuNi 90/10 alloy provides long service life in seawater systems.

-

Eccentric Design – Prevents air accumulation in pipelines, ensuring safe operation in condensers and cooling systems.

-

Complete Package – Delivered with C70600 pipes and flanges, guaranteeing perfect fit and material consistency.

-

Compliance – Produced according to ASTM B466 and ASME B16.9 standards.

-

Applications

-

Marine & Offshore Piping Systems – seawater cooling, ballast systems, firewater lines.

-

Desalination Plants – high-corrosion resistant piping components.

-

Power Plant Condensers – seawater cooling circuits.

-

Chemical & Petrochemical Facilities – handling corrosive media.

-

Oil & Gas Platforms – offshore and subsea piping applications.

Why Choose DLSS?

-

Complete supply of C70600 piping system components – pipes, flanges, reducers, elbows, and fittings.

-

Strict quality control and 100% inspection before shipment.

-

Export seaworthy packaging – reducers packed with matching C70600 pipes and flanges in ISPM-15 certified wooden cases.

-

Mill Test Certificates (EN 10204/3.1) provided, with optional third-party inspections (SGS, BV, TUV).

-

Frequently Asked Questions (FAQ)

Q1: Why choose C70600 CuNi 90/10 for reducers?

A1: Because it combines excellent seawater corrosion resistance, erosion resistance, and long service life in marine environments.

Q2: What’s the advantage of an eccentric reducer over concentric?

A2: Eccentric reducers prevent air pockets in horizontal pipelines, ensuring safe and efficient flow in condensers and seawater systems.

Q3: Can DLSS supply the full C70600 piping package?

A3: Yes, we supply reducers together with matching pipes and flanges, ensuring complete compatibility.

Q4: What inspections are included?

A4: Hydrostatic test, dimensional check, and material analysis. Additional NDT and third-party inspections available on request.