Product Description

DLSS supplies ASTM B466 C70600 (O60) seamless pipes in size 88.9 mm OD × 5.49 mm wall thickness × 3000 mm length, designed for demanding onshore and offshore piping systems. Manufactured in accordance with ASTM B466, these seamless copper-nickel pipes provide a reliable solution for seawater cooling, condensers, desalination, marine engineering, and petrochemical plants.

Material C70600 (CuNi 90/10) contains 90% copper and 10% nickel, with small additions of iron and manganese to improve resistance to seawater corrosion, erosion, and biofouling, ensuring long service life in harsh marine environments.

Condition O60 (annealed) offers excellent ductility and workability, making it suitable for fabrication and welding in complex piping systems.

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B466 |

| Material | C70600 Copper-Nickel (90/10) |

| Condition | O60 (Annealed) |

| Type | Seamless Pipe |

| Size | 88.9 mm OD × 5.49 mm WT × 3000 mm Length |

| Corrosion Resistance | Excellent in seawater, brackish water, and chloride-rich environments |

| Applications | Onshore & Offshore piping, condensers, desalination, petrochemical, power plants |

Key Features

-

Seamless Construction – Superior strength, pressure resistance, and smooth internal surface.

-

High Corrosion Resistance – CuNi 90/10 alloy ensures long-term reliability in seawater service.

-

Annealed Condition (O60) – Excellent ductility and weldability for complex installations.

-

Marine Proven – Trusted in offshore oil & gas, shipbuilding, and desalination projects worldwide.

-

Standards Compliance – Produced to ASTM B466, ensuring dimensional accuracy and quality.

Applications

-

Onshore & Offshore Piping Systems – seawater cooling and firewater lines.

-

Power Plant Condensers – seawater cooling systems.

-

Desalination Plants – highly resistant to brine and seawater corrosion.

-

Shipbuilding & Marine Engineering – engine cooling and ballast systems.

-

Petrochemical Industry – handling corrosive fluids in refinery and chemical plants.

Why Choose DLSS?

-

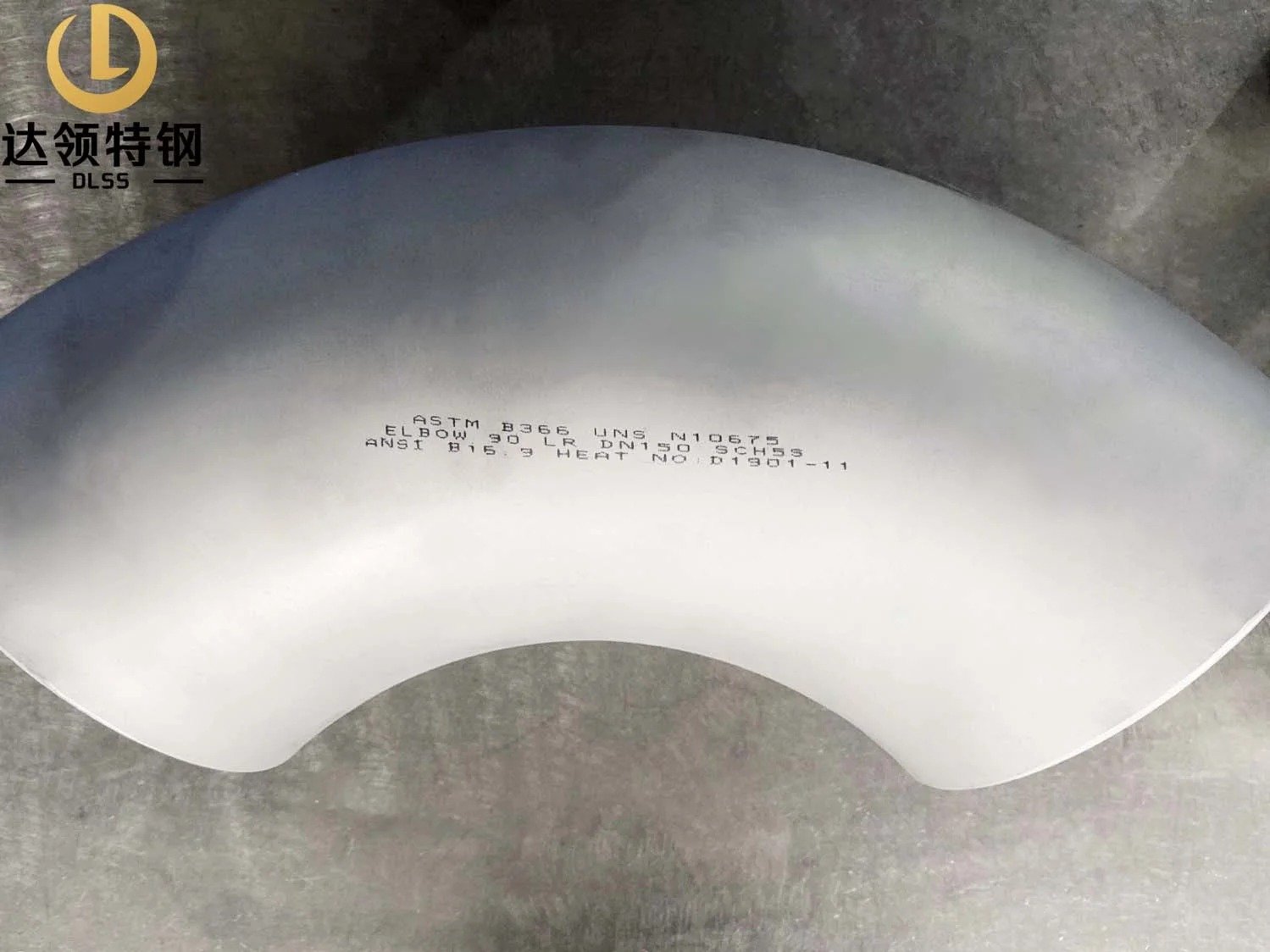

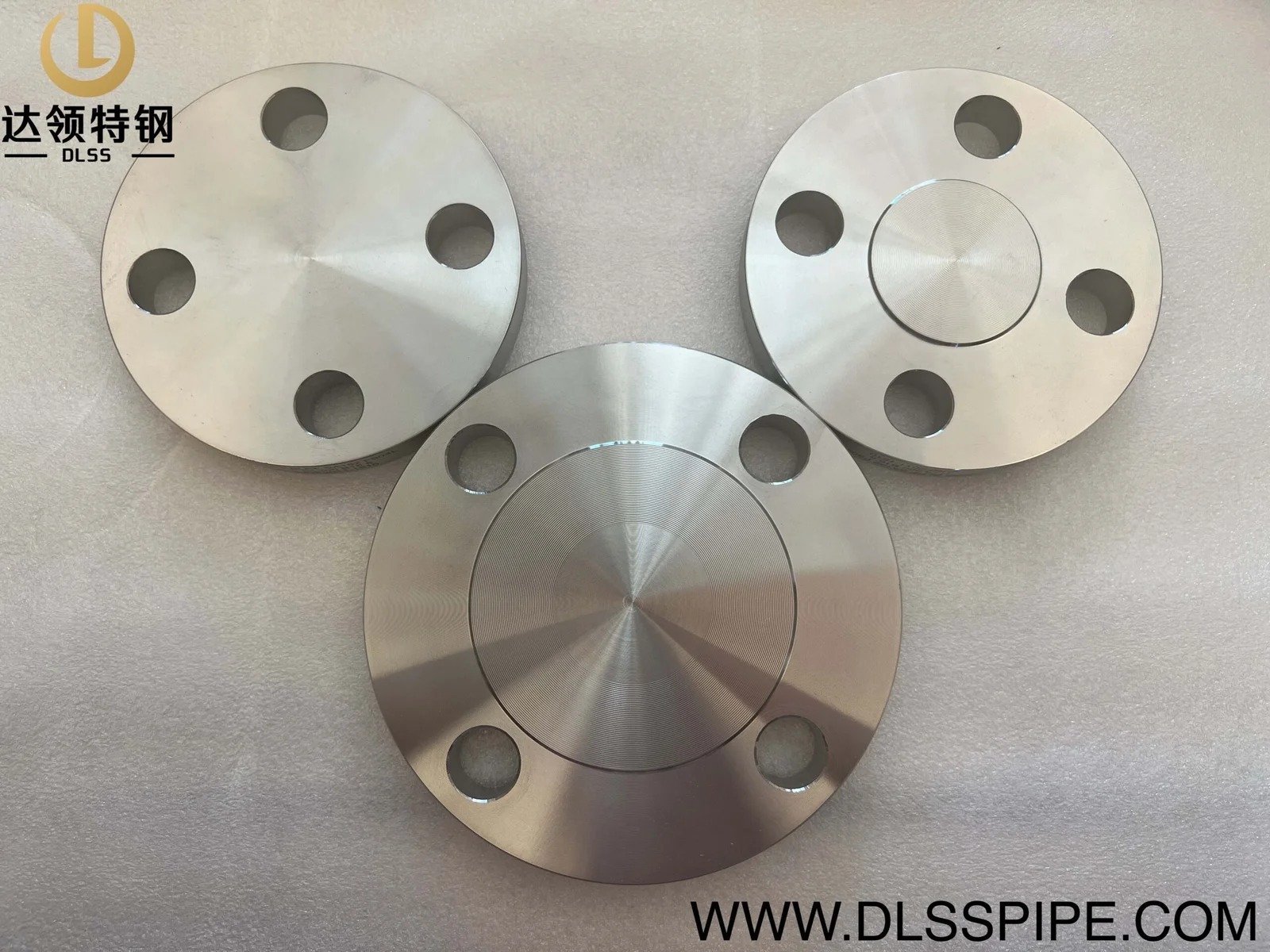

Complete supply of C70600 copper-nickel piping packages: pipes, flanges, reducers, and fittings.

-

Strict quality control with 100% dimensional, visual, and NDT inspections.

-

Mill Test Certificate EN 10204/3.1 included, with optional third-party inspection (SGS, BV, TUV).

-

Export seaworthy packaging: pipes delivered with end caps, plastic wrapping, and ISPM-15 wooden cases.

-

Frequently Asked Questions (FAQ)

Q1: What does O60 mean in C70600 pipes?

A1: O60 refers to the annealed condition, which provides improved ductility and workability for fabrication and welding.

Q2: Why is C70600 CuNi 90/10 used in offshore projects?

A2: It offers excellent resistance to seawater corrosion, erosion, and biofouling, making it highly reliable for marine service.

Q3: Can DLSS provide long lengths beyond 3000 mm?

A3: Yes, customized lengths and cut-to-size supply are available on request.

Q4: Do you supply complete piping systems?

A4: Yes, DLSS supplies pipes, fittings, and flanges in C70600 as a package solution.