Introduction

ASTM B729 Alloy 20 Seamless Pipe (UNS N08020), also known as Carpenter 20, is a nickel-iron-chromium austenitic alloy with copper and molybdenum additions, designed for superior resistance to sulfuric acid and chloride stress corrosion cracking.

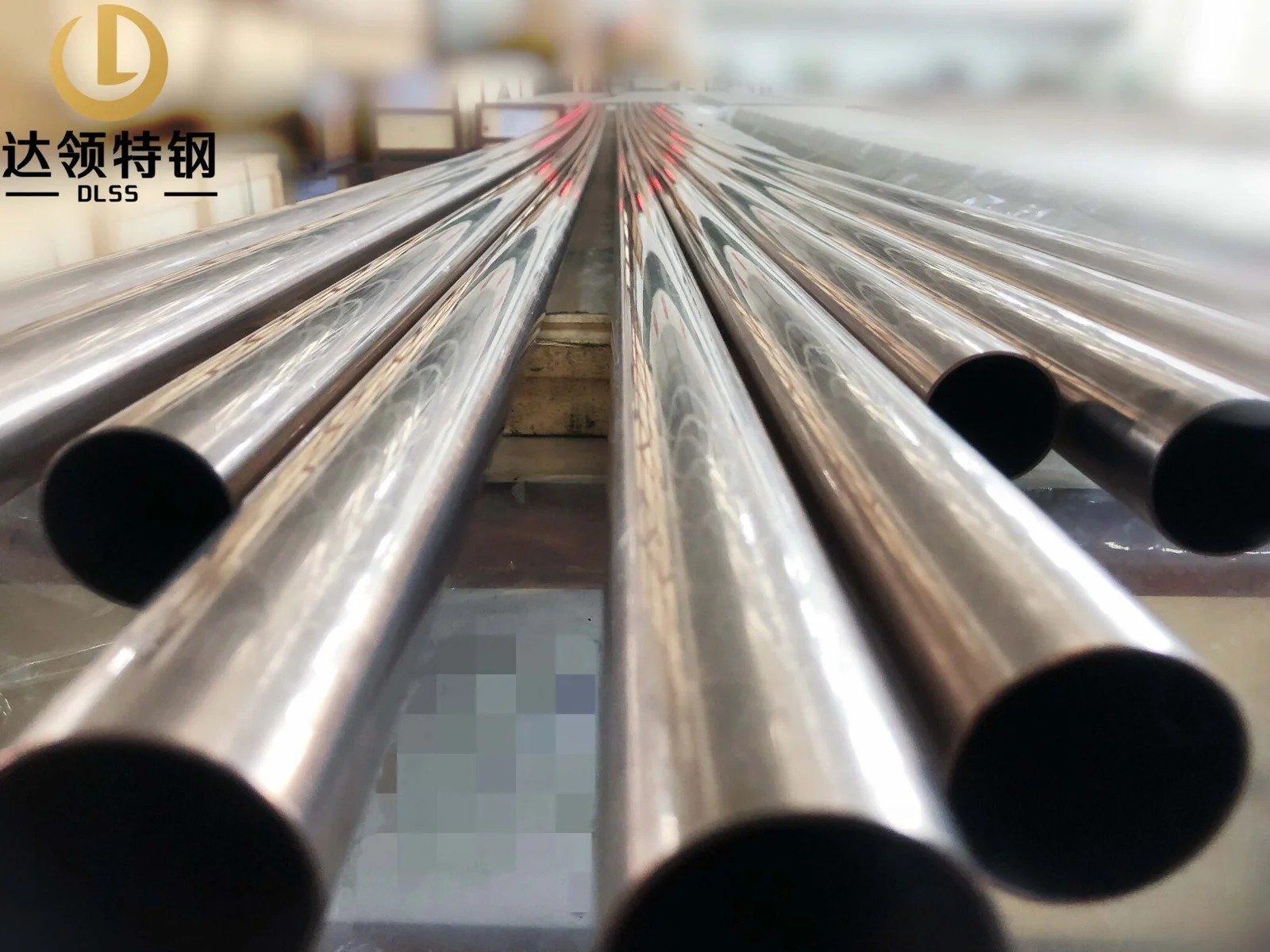

DLSS supplies Alloy 20 seamless pipes in size 88.9 mm OD × 4.0 mm WT × 6000 mm length, manufactured to ASTM B729 and solution annealed with excellent dimensional accuracy. This batch is prepared for export to Saudi Arabia, where Alloy 20 is widely applied in chemical and petrochemical industries due to the region’s demand for corrosion-resistant materials in sulfuric acid and chloride-rich processing plants.

Why Choose Alloy 20?

-

Superior Sulfuric Acid Resistance – handles H₂SO₄ across a wide concentration range.

-

Chloride SCC Resistance – reliable in seawater, brine, and high-chloride conditions.

-

Balanced Alloy Design – nickel, chromium, molybdenum, and copper ensure multi-acid corrosion resistance.

-

Cost-Effective Alternative – performs better than 316L/317L stainless steel, at a lower cost than Hastelloy.

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B729 |

| Material | Alloy 20 (UNS N08020) |

| Type | Seamless Pipe |

| Size | 88.9 mm OD × 4.0 mm WT × 6000 mm Length |

| Condition | Solution Annealed |

| Destination | Saudi Arabia |

| Applications | Sulfuric acid service, chemical plants, petrochemical units, offshore systems |

Applications in Saudi Arabia

Saudi Arabia’s chemical and petrochemical industries have significant demand for nickel alloys such as Alloy 20 due to their excellent corrosion resistance in aggressive environments:

-

Sulfuric Acid Production Plants – reactors, piping, and heat exchangers.

-

Petrochemical Units – scrubbers, evaporators, and storage tanks.

-

Offshore & Marine – seawater cooling systems exposed to chlorides.

-

Refineries – piping systems where chloride SCC is a major risk.

Why DLSS?

-

Expertise in nickel alloy seamless pipe supply including Alloy 20, Incoloy, Inconel, Hastelloy, Monel.

-

Quality Control – 100% Eddy Current, Hydrostatic, UT, and PMI testing.

-

Third-Party Inspection – SGS, BV, TUV accepted for Saudi projects.

-

Export Packaging – plastic capped ends, seaworthy ISPM-15 wooden cases.

-

Middle East Supply Record – long-term supply to Saudi Arabia, UAE, Kuwait, and Oman for EPC and oil & gas projects.