Introduction

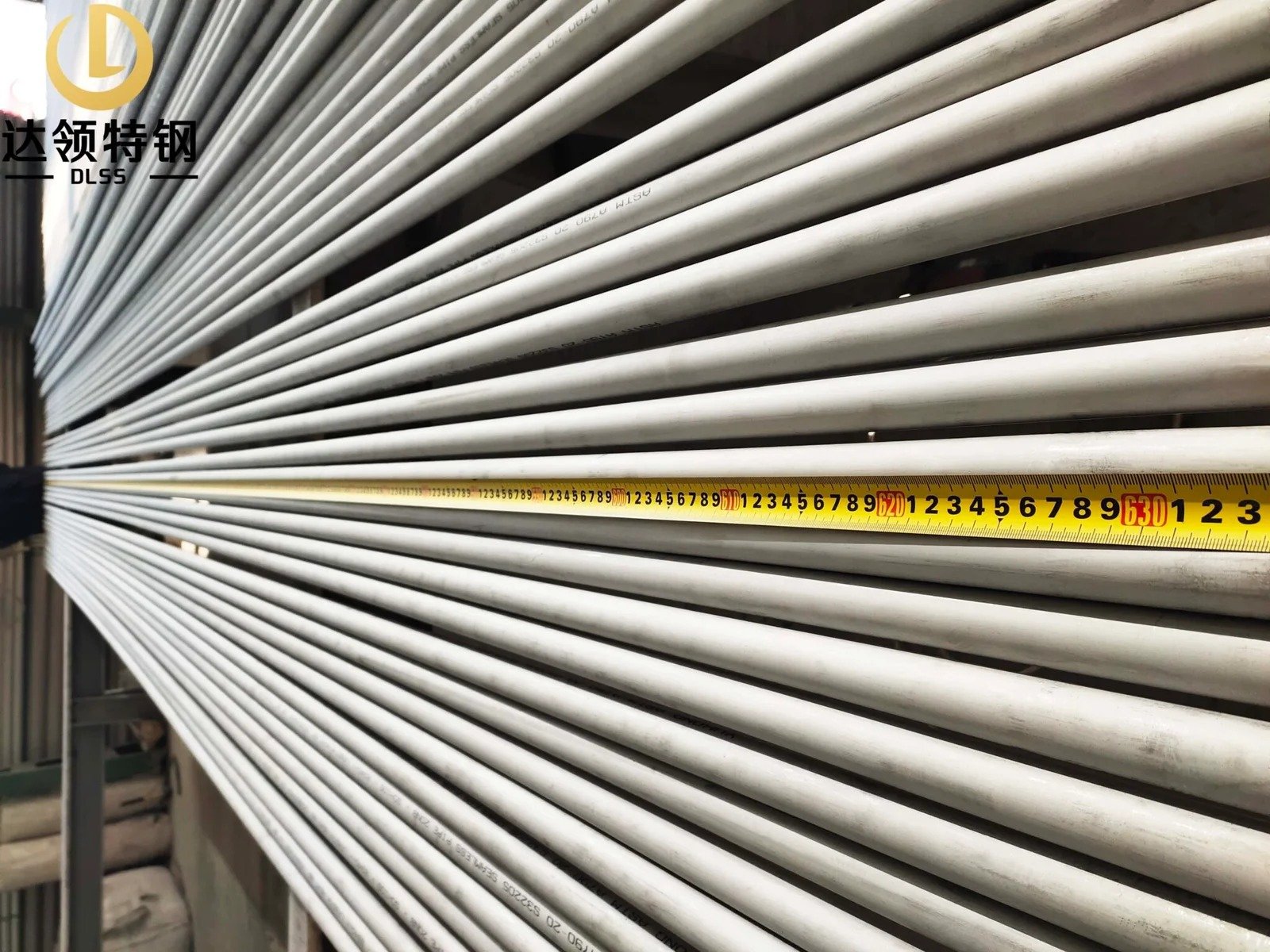

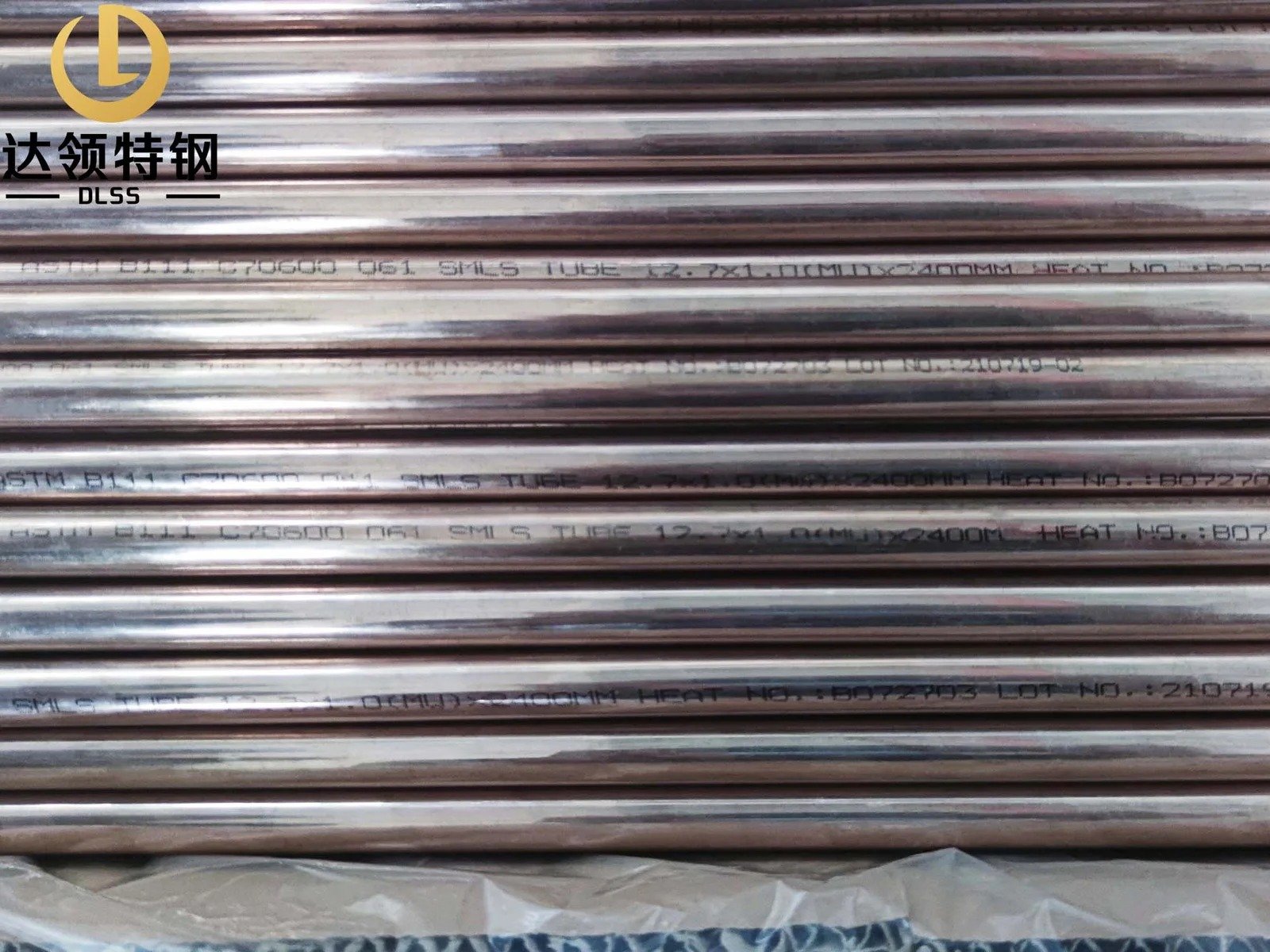

When it comes to condenser and heat exchanger tubing, Aluminum Brass C68700 (O61) is one of the most reliable materials for seawater and cooling water service. DLSS supplies ASTM B111 compliant seamless tubes with dimensions 19 mm OD × 1.6 mm wall thickness × 3000 mm length, fully tested to ensure 100% integrity through Eddy Current Testing.

These tubes are widely applied in power plants, desalination facilities, marine engineering, and industrial condensers, where durability and heat transfer efficiency are critical.

Material Overview – Aluminum Brass C68700

Aluminum Brass C68700 (UNS C68700) is a copper-zinc-aluminum alloy, enhanced with small additions of arsenic to improve corrosion resistance. It offers:

-

Excellent seawater corrosion resistance – suitable for brackish water and polluted river water.

-

Resistance to dezincification and impingement attack – even at high flow velocities.

-

High thermal conductivity – ensuring efficient heat transfer in condensers and exchangers.

-

Anti-biofouling properties – reduced risk of marine organism growth.

Specifications

| Item | Details |

|---|---|

| Standard | ASTM B111 |

| Material | Aluminum Brass C68700 (O61) |

| Dimensions | 19 mm OD × 1.6 mm Wall Thickness × 3000 mm Length |

| Type | Seamless Tube |

| Heat Treatment | O61 (Annealed) |

| Non-Destructive Test | 100% Eddy Current Testing |

| Application | Condenser, Heat Exchanger, Seawater Cooling Systems |

Key Features

-

Seamless Construction – Superior dimensional accuracy and strength.

-

100% Eddy Current Testing – Guarantees defect-free tubes and reliability in operation.

-

Excellent Corrosion Resistance – Long service life in seawater, desalination, and industrial cooling.

-

Optimized Heat Transfer – High conductivity ensures efficient energy performance.

-

Applications

-

Power Plant Condensers

-

Marine Condensers and Coolers

-

Desalination Plants

-

Heat Exchangers for Chemical and Petrochemical Industry

-

Seawater Cooling Systems

Why Choose DLSS Aluminum Brass Tubes?

-

Compliance with ASTM B111 and international standards.

-

Strict Quality Control – Each tube is 100% Eddy Current Tested before shipment.

-

Reliable Export Packaging – Bundled or wooden cases with end caps to prevent damage.

-

Proven Supply – Trusted by clients worldwide for condenser and exchanger projects.

-

Frequently Asked Questions (FAQ)

Q1: Why is Aluminum Brass C68700 preferred for condensers?

A1: Because it resists seawater corrosion, impingement attack, and biofouling, ensuring long-term reliability in cooling systems.

Q2: What does O61 mean?

A2: O61 indicates the annealed condition, providing good ductility and workability.

Q3: What inspections are carried out?

A3: Each tube undergoes 100% Eddy Current Testing for surface and internal defects, with Mill Test Certificates (EN 10204/3.1) provided.

Q4: Can DLSS supply customized lengths?

A4: Yes, lengths and tolerances can be tailored according to customer requirements.