Introduction

The EN10216-5 1.4841 (TP314) Seamless Pipe is a high-temperature resistant stainless steel pipe widely used in heat exchangers, boilers, and industrial furnaces. With its high chromium (24–26%) and nickel (19–22%) content, TP314 provides excellent resistance to oxidation, scaling, and carburization at elevated service conditions.

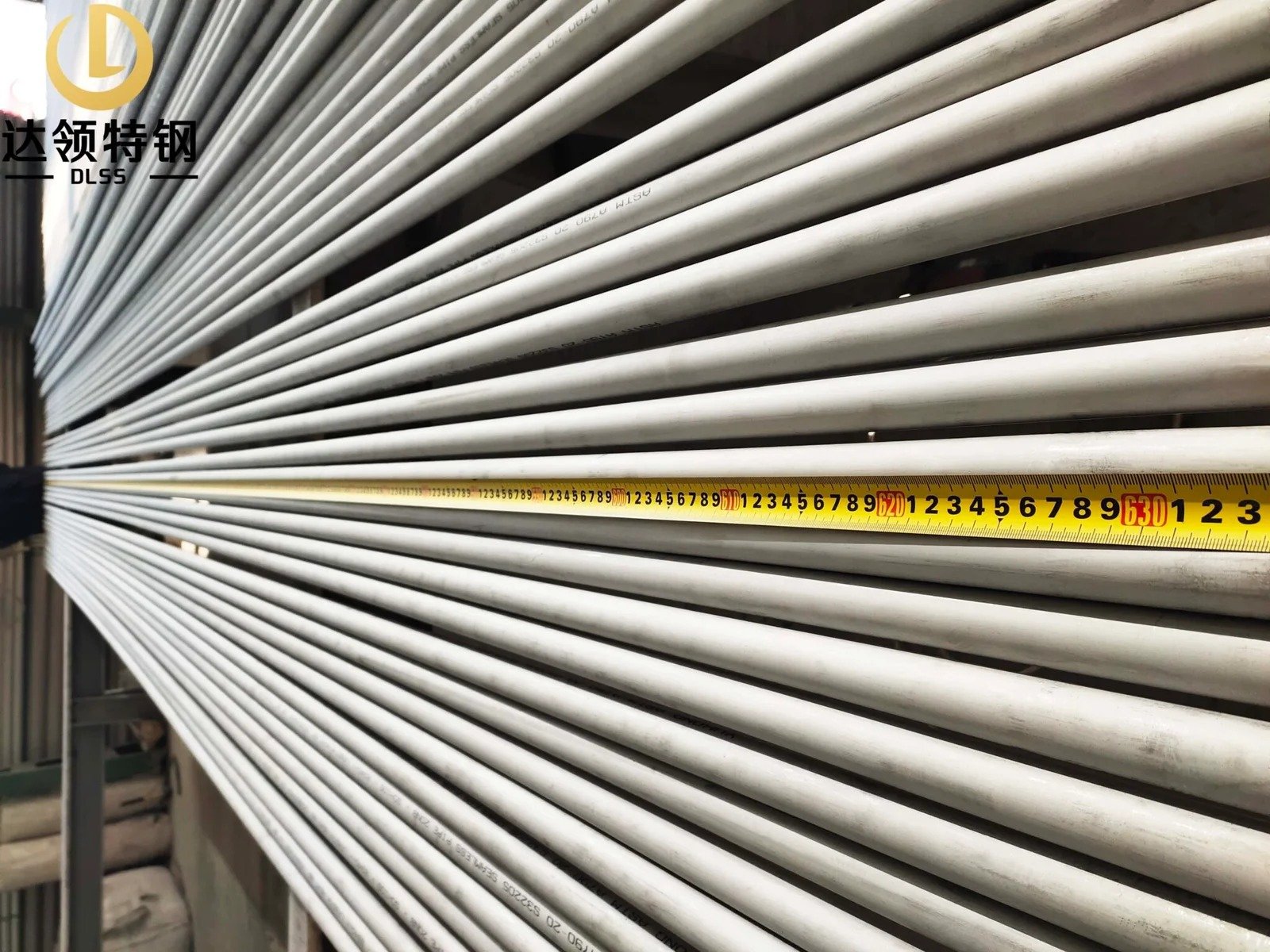

DLSS supplied 60.3 mm OD × 10 mm WT × 4717 mm length seamless pipes, precisely manufactured according to EN10216-5 standards, ensuring superior strength, durability, and performance in heat exchanger applications.

Key Features

-

Material: Stainless Steel 1.4841 (TP314)

-

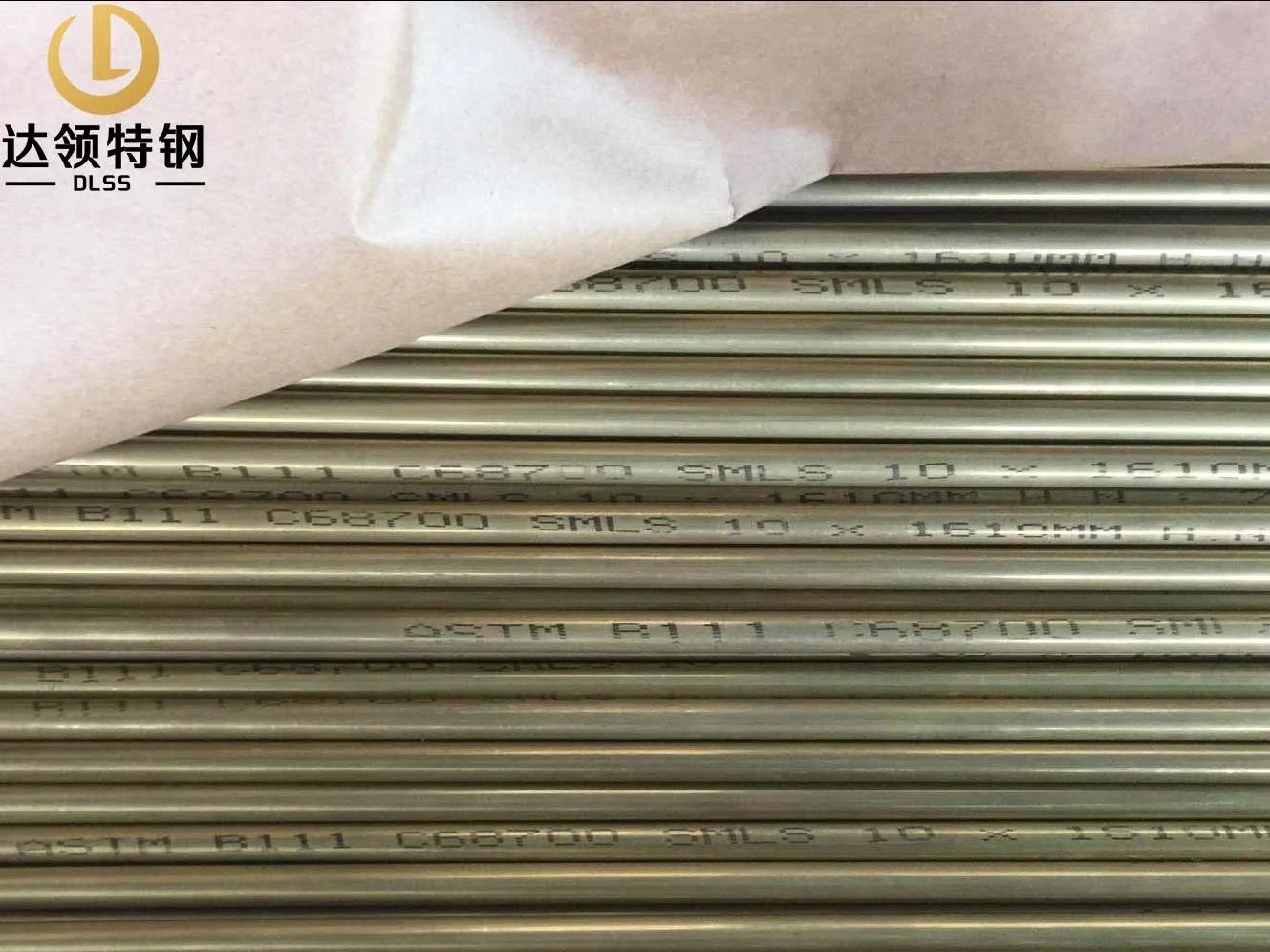

Standard: EN10216-5 (Seamless Stainless Steel Tubes for Pressure Purposes)

-

Type: Seamless Pipe (SMLS)

-

Size: 60.3 mm OD × 10 mm WT × 4717 mm Length

-

Grade Properties: High-temperature stainless steel with excellent oxidation resistance

-

Application: Heat Exchangers, Boilers, Industrial Furnaces, Petrochemical Plants

Specifications

| Item | Details |

|---|---|

| Standard | EN10216-5 |

| Material | 1.4841 (TP314 Stainless Steel) |

| Type | Seamless Pipe |

| Size | 60.3×10×4717 mm |

| Applications | Heat Exchangers, Boilers, Power Generation, Chemical & Refinery Piping |

| Properties | High strength, oxidation & scaling resistance, carburization resistant |

Advantages of 1.4841 (TP314)

-

High Temperature Resistance – stable performance in continuous service above 1000°C.

-

Excellent Oxidation Resistance – withstands scaling in air and combustion gases.

-

Carburization Resistance – suitable for hydrocarbon and furnace environments.

-

Durability – thick wall (10 mm) enhances mechanical strength under pressure.

-

Versatile Applications – ideal for demanding heat exchanger and boiler services.

Applications

-

Heat Exchangers – handling high-temperature gases and fluids.

-

Boilers & Superheaters – resistant to oxidation and thermal cycling.

-

Petrochemical Plants – furnace tubes, refinery piping.

-

Power Generation – piping for steam and hot gases.

-

Industrial Furnaces – structural and piping components at extreme heat.

Quality Assurance

DLSS ensures every pipe meets strict quality standards:

-

PMI Testing to confirm grade 1.4841 (TP314).

-

Dimensional Accuracy for tight tolerances in exchanger assemblies.

-

Heat Treatment Records for traceable stability.

-

NDT (UT, ET, RT) and hydrostatic testing available upon request.

-

Third-Party Inspection (SGS, BV, TUV, LR) provided if required.

FAQ

Q1: What makes TP314 different from TP321/TP347?

A1: TP314 has higher chromium and nickel content, making it more suitable for continuous high-temperature service and oxidation resistance.

Q2: Can 1.4841 pipes be used in heat exchangers with hot gases?

A2: Yes, they are widely used in high-temperature gas and furnace environments due to their oxidation resistance.

Q3: Why choose thick-wall (10 mm) seamless pipes?

A3: Thick walls provide higher pressure resistance and extend service life in demanding exchanger conditions.

Why Choose DLSS?

-

30+ years of experience in high-temperature stainless steels.

-

Global supply references in power plants, refineries, and offshore projects.

-

Strict QC including PMI, HT, NDT, and hydro tests.

-

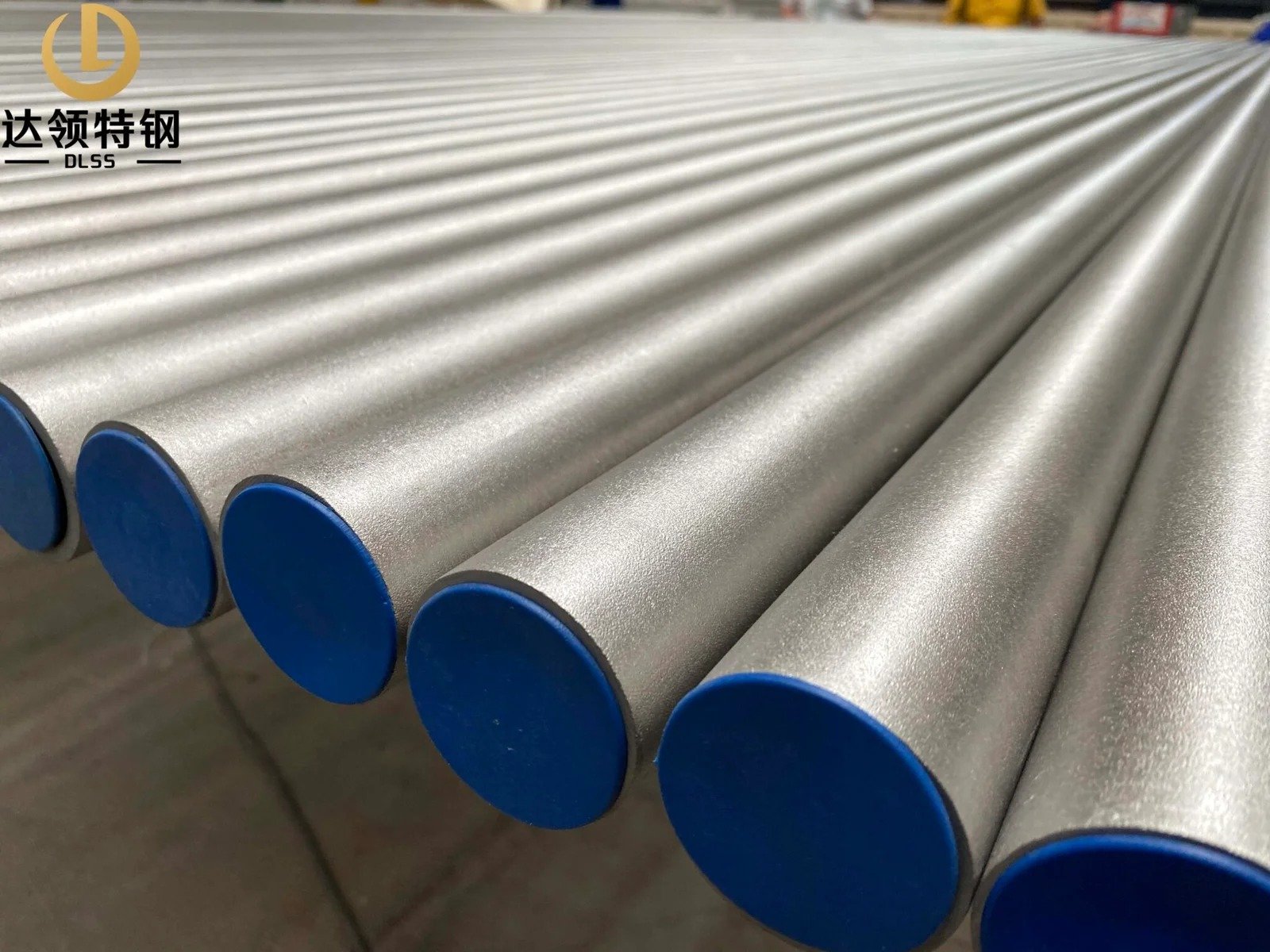

Seaworthy packaging with plastic caps, PE wrap, and wooden cases.