Introduction

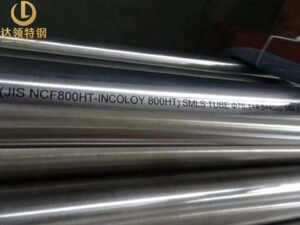

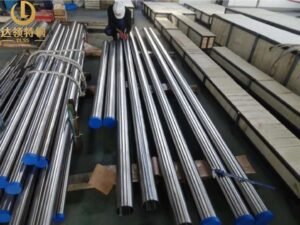

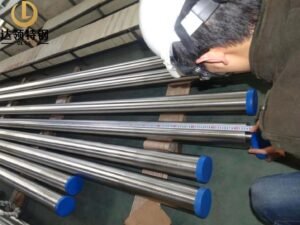

JIS NCF800HT Incoloy 800HT Seamless Tube is a high-temperature nickel-iron-chromium alloy tube, well known for its excellent resistance to oxidation, carburization, and stress rupture. DLSS supplies seamless tubes in size 76.1 mm OD × 4.5 mm WT × 4520 mm length, manufactured to JIS standards and finished with a bright surface for improved cleanliness, corrosion resistance, and smooth heat transfer.

This product is widely used in heat exchangers, chemical processing, power generation, and thermal equipment, where stability at elevated temperatures and long-term creep resistance are critical.

What is Incoloy 800HT (JIS NCF800HT)?

Incoloy 800HT (UNS N08811) is a modified version of Incoloy 800H with tighter control of carbon, aluminium, and titanium content. Its composition provides:

-

Nickel (30–35%)

-

Chromium (19–23%)

-

Iron (balance)

-

Al + Ti (0.85–1.20%)

Key properties of JIS NCF800HT – Incoloy 800HT Seamless Tube include:

-

Excellent resistance to oxidation and carburization at high temperatures

-

High creep and stress rupture strength above 600°C

-

Good structural stability under prolonged service

-

Widely used in heat exchangers, furnace components, and chemical plants

Specifications

| Item | Details |

|---|---|

| Standard | JIS NCF800HT / ASTM B407 / ASME SB407 |

| Material | Incoloy 800HT (UNS N08811) |

| Type | Seamless Tube |

| Size | 76.1 mm OD × 4.5 mm WT × 4520 mm Length |

| Surface Finish | Bright Surface |

| Applications | Heat exchangers, petrochemical heaters, reformer tubes, power plants |

Key Features of JIS NCF800HT Incoloy 800HT Seamless Tube

-

Bright Surface Finish – smooth, oxide-free surface improves heat transfer efficiency.

-

High Temperature Strength – excellent creep and rupture resistance above 600°C.

-

Oxidation Resistance – stable performance up to 1100°C in air and flue gases.

-

Carburization Resistance – suitable for hydrocarbon processing equipment.

-

Seamless Integrity – ensures high reliability in pressure and thermal cycling conditions.

Applications

-

Heat Exchangers & Condensers – operating under high temperature and corrosive gases.

-

Petrochemical Industry – furnace tubes, ethylene crackers, hydrogen reformers.

-

Power Plants – boiler tubes, superheater and reheater tubes.

-

Thermal Processing Equipment – kilns, heat-treatment fixtures, and gas turbine components.

-

Chemical Plants – handling nitric acid, sulfur compounds, and oxidation processes.

Why Choose DLSS?

-

Full range of nickel alloy tubes and pipes – Incoloy, Inconel, Monel, Hastelloy.

-

Strict Quality Control – 100% HT/ET/UT + PMI + dimensional checks.

-

Third-Party Inspections – SGS, BV, TUV available.

-

Export Packaging – capped ends, plastic wrapped, ISPM-15 seaworthy wooden cases.

-

Global Supply – delivered to chemical plants, power stations, and refinery projects worldwide.

Frequently Asked Questions (FAQ)

Q1: Why use JIS NCF800HT Incoloy 800HT in heat exchangers?

A1: It provides excellent resistance to oxidation and carburization, with superior long-term strength at high temperatures.

Q2: What is the difference between Incoloy 800H and 800HT?

A2: 800HT has controlled carbon, aluminium, and titanium content, giving better creep and rupture resistance.

Q3: What is the benefit of Bright Surface finishing?

A3: It ensures a smooth and oxide-free tube surface, minimizing fouling and maximizing heat transfer efficiency.

Q4: Can DLSS supply U-bend Incoloy 800HT tubes?

A4: Yes, straight, U-bent, and finned Incoloy 800HT tubes are available for heat exchangers.