Meta Description:

Confused by ASTM A213, A269, and A312 standards? Learn the key differences in scope, testing, and application for these stainless steel tube specifications to choose the right product for your project.

Introduction

When sourcing stainless steel tubes, choosing the correct ASTM standard is critical for compliance, safety, and performance. Among the most commonly used specifications are:

- ASTM A213 – Seamless tubes for high-temperature service

- ASTM A269 – Welded/seamless tubes for general corrosion-resisting applications

- ASTM A312 – Heavy-duty pipes for pressure service

Each standard serves a specific purpose and comes with unique mechanical, dimensional, and testing requirements. This guide will help you understand the differences and select the right standard for your needs.

1. Overview of Each ASTM Standard

| Standard | Tube Type | Main Application |

|---|---|---|

| ASTM A213 | Seamless only | Heat exchanger, boiler, superheater |

| ASTM A269 | Seamless/Welded | General-purpose fluid transport |

| ASTM A312 | Seamless/Welded | Pressure piping, industrial pipework |

2. Key Differences Between A213, A269, and A312

| Feature | ASTM A213 | ASTM A269 | ASTM A312 |

|---|---|---|---|

| Tube Type | Seamless | Seamless or welded | Seamless or welded |

| Wall Thickness | Usually thinner (calculated) | Medium | Thick-walled |

| Application | Heat exchanger, boiler | Food, chemical, general tubing | Structural, pressure pipe |

| Surface Finish | BA, pickled | BA, polished, pickled | Pickled or polished |

| Nondestructive Testing | Mandatory ET or hydrostatic | ET/hydro recommended | Hydrostatic required |

| Mechanical Tests | Flattening, flaring, hardness | Flattening, flange, reverse bend | Tensile, flattening, bend, hydro |

3. Choosing the Right Standard – Application-Based Guide

| Application | Recommended Standard |

|---|---|

| Shell-and-tube heat exchangers | ASTM A213 |

| High-pressure fluid piping | ASTM A312 |

| Food-grade water transfer systems | ASTM A269 |

| Superheated steam lines (Power plants) | ASTM A213 |

| Corrosive chemical piping | ASTM A312 or A269 |

| Condensers and U-bend tubes | ASTM A213 |

For a complete list, refer to ASTM’s official standards database

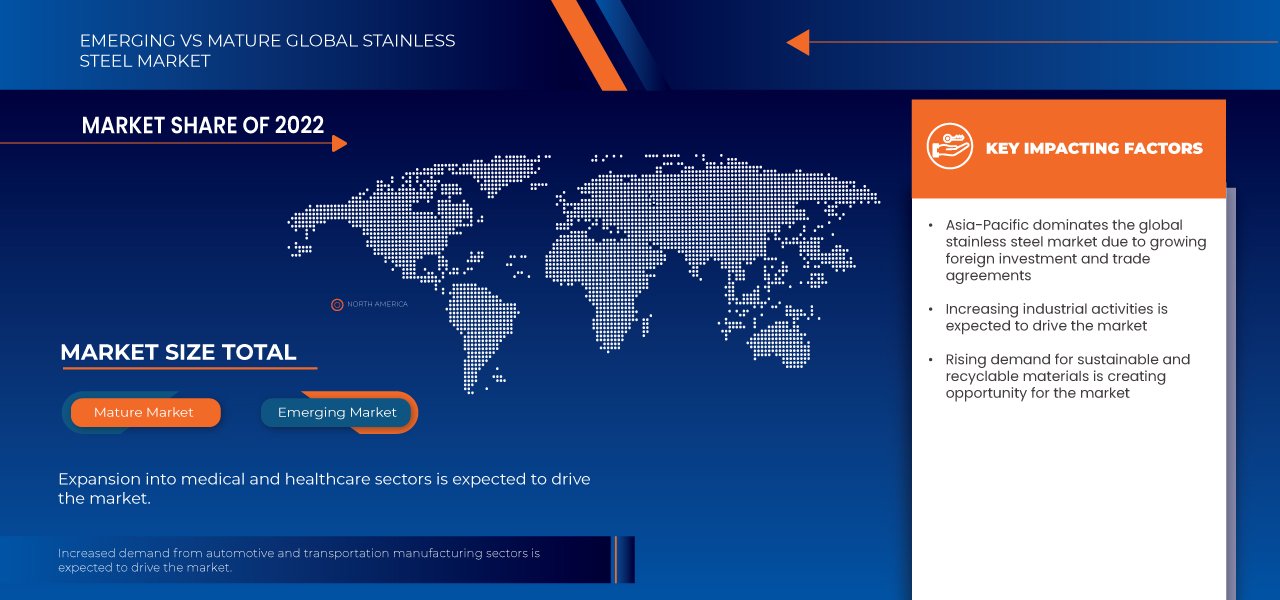

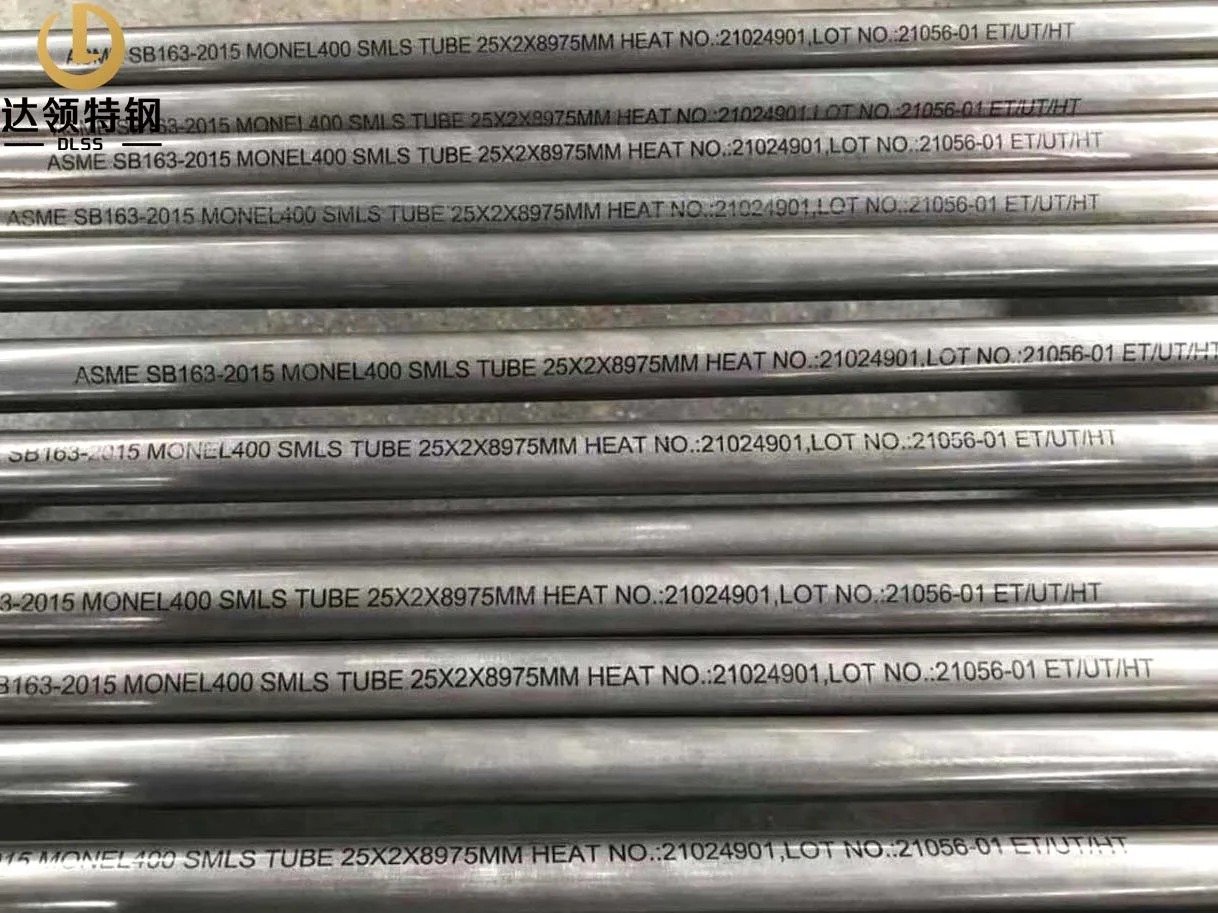

4. DLSS Product Range According to Standards

| Standard | Grades Available | Size Range (OD × WT) | Surface Finish |

|---|---|---|---|

| A213 | TP304/L, TP316/L, TP321, TP347 | 6–50.8 mm × 0.5–3.0 mm | BA, Pickled |

| A269 | TP304/L, TP316/L, TP904L | 6–76 mm × 0.5–2.5 mm | BA, Polished, EP |

| A312 | TP304/L, TP316/L, Duplex 2205 | 21.3–219.1 mm × 2.0–12.7 mm | Pickled, Polished |

DLSS can also supply custom U-bend and corrugated tubes for heat exchangers per ASTM A213.

5. Cost and Lead Time Considerations

- ASTM A213 tubes are more expensive due to seamless manufacturing and stricter testing

- ASTM A269 offers flexibility with welded options for less demanding uses

- ASTM A312 pipes have higher material cost due to wall thickness and size

Selecting the correct standard avoids over-specification and reduces procurement cost without compromising on safety or performance.

FAQs

Q1: Can I use ASTM A269 tubes in a boiler application?

No. For high-pressure, high-temperature applications, ASTM A213 is required due to its testing and dimensional tolerance.

Q2: Are A312 pipes available with NACE MR0175 certification?

Yes. DLSS can supply A312 pipes with full MTC and NACE compliance for sour gas service.

Q3: What is the surface roughness of A269 BA tubes?

Typical internal Ra ≤ 0.2 µm. For EP tubes (electropolished), Ra ≤ 0.05 µm.

Q4: Can DLSS offer 3.2-certified material for these standards?

Yes. We provide 3.2 inspection with Lloyd’s, BV, SGS or TÜV as required.

Conclusion

Understanding the difference between ASTM A213, A269, and A312 is essential for selecting the right stainless steel tubing. DLSS provides seamless and welded solutions to meet every specification—with global shipping, technical support, and full traceability.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Still unsure which standard fits your application? Our engineers are ready to help you make an informed decision.