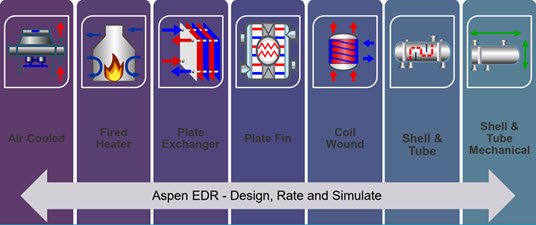

Heat exchanger tubes are the backbone of many critical industries, including oil & gas, power generation, petrochemicals, shipbuilding, and desalination. Choosing the right tube material and ensuring compliance with international standards are essential to guarantee safety, efficiency, and long-term performance.

In this article, we provide a detailed overview of standards, materials, manufacturing processes, and applications of heat exchanger tubes.

What Are Heat Exchanger Tubes?

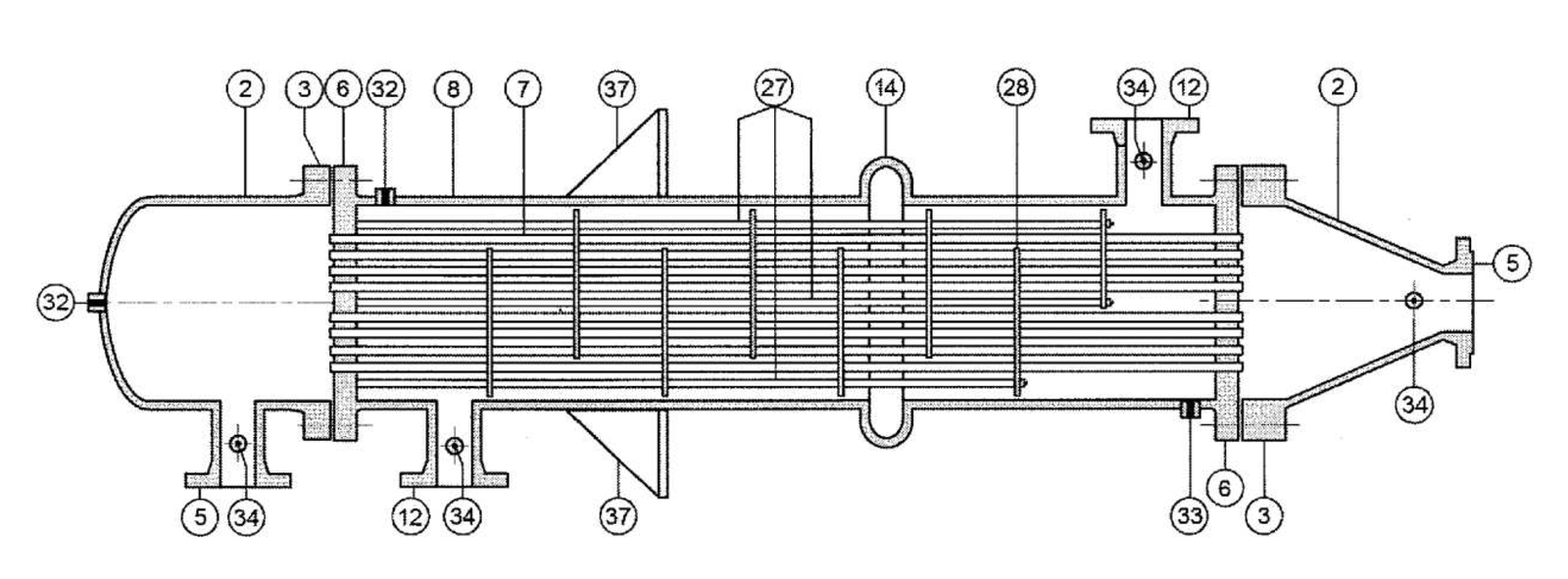

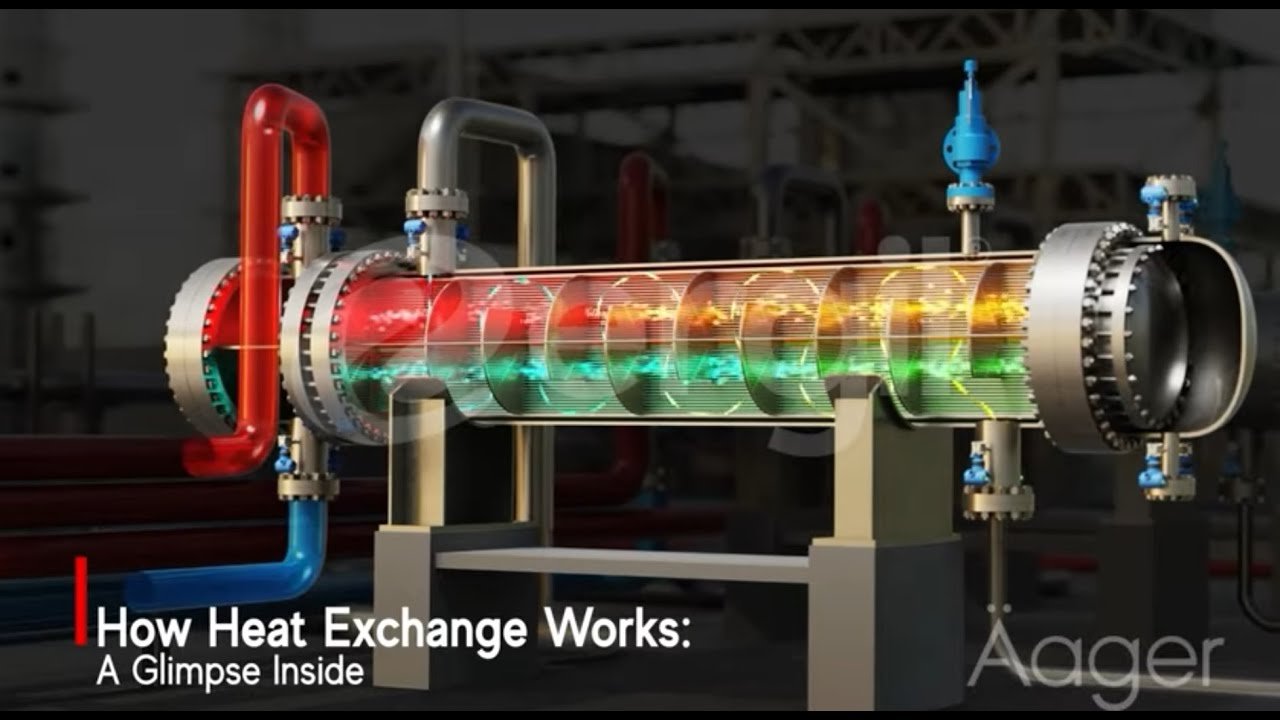

Heat exchanger tubes are specially designed seamless or welded tubes used in heat transfer systems, such as boilers, condensers, and process equipment. They must withstand high temperatures, pressure fluctuations, and corrosive environments.

Learn more about our Heat Exchanger Tubes.

International Standards for Heat Exchanger Tubes

Heat exchanger tubes must comply with global standards to ensure material consistency and mechanical reliability:

- ASTM / ASME: ASTM A213, A312, A789, ASME SA213

- EN / DIN: EN 10216-5, DIN 17458

- JIS: JIS G3463

These standards define chemical composition, mechanical properties, and testing requirements to meet the demanding conditions of heat exchanger applications.

Common Materials for Heat Exchanger Tubes

- Austenitic Stainless Steel

- TP304 / 304L, TP316 / 316L, TP321, TP347

- Excellent corrosion resistance and high-temperature strength.

- Duplex and Super Duplex Stainless Steel

- S32205 (2205), S32750 (2507)

- Superior resistance to chloride stress corrosion cracking.

- High-Performance Alloys

- 904L, 6Mo (UNS S31254)

- Ideal for seawater desalination and chemical processing.

- Copper and Copper Alloys

- C70600 (90/10 CuNi), C71500 (70/30 CuNi), C44300

- Excellent thermal conductivity, widely used in shipbuilding and condensers.

See also: Stainless Steel Seamless Tubes

Manufacturing & Inspection of Heat Exchanger Tubes

Heat exchanger tubes must undergo rigorous production and testing to meet quality requirements:

- Manufacturing: Hot extrusion, cold drawing, bright annealing.

- Heat Treatment: Bright annealing ensures a smooth surface and consistent mechanical properties.

- Non-Destructive Testing (NDT):

- Eddy Current Test (ET)

- Ultrasonic Test (UT)

- Hydrostatic Pressure Test

- Positive Material Identification (PMI)

Learn more about our Quality Control.

Applications of Heat Exchanger Tubes

- Oil & Gas Refineries: Processing units, coolers, heaters.

- Power Generation: Boiler tubes, condensers, superheaters.

- Petrochemical Industry: Heat transfer in chemical reactors.

- Shipbuilding & Marine: Condensers, seawater desalination plants.

- Renewable Energy: Geothermal and solar thermal power projects.

Why Choose DLSS for Heat Exchanger Tubes?

At DLSS (Zhejiang Daling Special Steel Co., Ltd.), we supply heat exchanger tubes that meet ASTM/ASME/EN/JIS standards and are trusted by clients in over 40 countries worldwide.

Our advantages include:

- 30+ years of manufacturing expertise.

- A full range of stainless steel, duplex, super duplex, and copper alloy tubes.

- Certified by ABS, DNV-GL, BV, LR, NK, PED, AD2000, CCS, ISO, and API.

- Proven track record with EPC contractors, refineries, and power plants.

Conclusion

Heat exchanger tubes are vital components for industrial systems where efficiency and durability are crucial. By choosing the right materials and a trusted supplier, you minimize risks and ensure operational reliability.

At DLSS, we deliver precision-manufactured tubes, complete with Mill Test Certificates (MTCs), third-party inspections, and reliable global logistics.

Learn more about our Heat Exchanger Tubes

Contact us today to request a quote or technical consultation.