Meta Description:

A comprehensive guide to U-bend stainless steel tubes for heat exchangers. Learn how to specify bending radius, wall thinning limits, tolerance, surface finish, and inspection standards.

Introduction

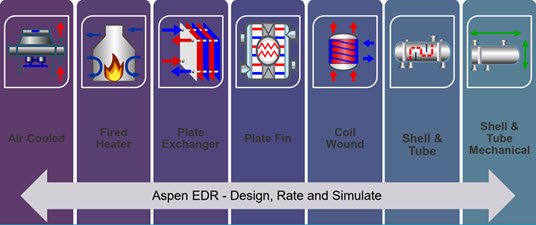

U-bend stainless steel tubes are a critical component in shell and tube heat exchangers, designed to increase heat transfer area while optimizing space. These tubes must meet strict dimensional, metallurgical, and mechanical standards to perform reliably under thermal cycling and high-pressure environments.

This article guides you through the key specifications and considerations when sourcing U-bend tubes for industrial heat exchanger applications.

1. What Are U-Bend Stainless Steel Tubes?

U-bend tubes are stainless steel tubes that are mechanically or thermally bent into a U-shape. Commonly used in heat exchangers for:

- Petrochemical plants

- Power generation boilers

- Seawater desalination

- Refineries and gas processing units

They eliminate the need for return headers and allow compact bundle design.

2. Common Materials for U-Bend Tubes

| Grade | Standard | Key Features |

|---|---|---|

| TP304 / TP304L | ASTM A213 | General-purpose, moderate corrosion resistance |

| TP316 / TP316L | ASTM A213 | High chloride resistance |

| TP321 / TP347 | ASTM A213 | Stabilized grades for high-temp service |

| S32205 Duplex | ASTM A789 | High strength, excellent SCC and pitting resistance |

| C70600 / C44300 | ASTM B111 | Admiralty and CuNi alloys for marine applications |

3. Bending Radius (R): How to Specify

- Standard Bending Radius: 1.5 × OD (Outside Diameter)

- Custom Radius: 2D, 3D, or as per drawing

- Tight Radius (<1.5D) may increase wall thinning risk

Tip: Confirm if the radius is inner or centerline for precise fabrication.

4. Wall Thinning Allowance

During bending, wall thinning occurs on the outer arc. Most specs limit thinning to:

- ≤10% of nominal wall thickness for critical service

- Wall thickness must remain above minimum ASTM requirement

DLSS Testing: We perform ultrasonic or micrometer inspection after bending.

5. Tolerances and Dimensional Control

| Parameter | Tolerance |

|---|---|

| Leg length | ±1.5 mm (or per customer drawing) |

| Centerline radius | ±1.5 mm |

| Ovality (OD) | ≤10% difference max |

| Wall thinning | ≤10% (unless otherwise specified) |

DLSS provides full dimensional inspection reports upon request.

6. Heat Treatment: Stress Relief Post-Bending

To avoid stress cracking, especially in austenitic stainless steel and duplex grades, U-bend tubes must undergo:

- Bright annealing or

- Solution annealing at 1050–1150°C

- Quenching (water/air) to stabilize grain structure

DLSS performs furnace-controlled annealing in inert atmosphere for mirror-clean inner surface.

7. Surface Finish

Options include:

- Pickled & Passivated (standard)

- Bright Annealed (pharma or food-grade)

- Polished (for decorative or hygienic applications)

Recommended Ra (roughness) for clean applications: ≤0.5 μm

8. Packing & Handling of U-Bend Tubes

Proper packaging is essential to avoid damage during shipment.

- Packed in customized wooden frames or crates

- Each leg supported to prevent stress at the bend

- Ends protected with plastic or rubber caps

- Tags include heat number, size, grade, and standard

DLSS ships globally with export-compliant packing per ASTM A700

9. Testing & Inspection for U-Bend Tubes

DLSS offers full QA/QC per ASTM, ASME, and client specs:

- Hydrostatic or Pneumatic Test

- Eddy Current Testing (ECT)

- Hardness Test

- Intergranular Corrosion (IGC) Test

- Grain Size Measurement

- EN 10204 3.1 / 3.2 Certification

- Third-Party Inspection (SGS, TUV, BV)

10. Common Standards Referenced

- ASTM A213 (TP304/316/321)

- ASTM A789 (Duplex)

- ASTM B111 (C44300 / C70600)

- ASME SA213 / SA789

- TEMA R / C / B Class Heat Exchanger Design

- EN 10216-5 for seamless stainless tubes

- NACE MR0175 for sour service

SEO Keywords

U-bend stainless steel tube, heat exchanger U tubes, stainless U tubes bending radius, TP316L U tube specification, ASTM A213 U bend tube, seamless U tube supplier, duplex steel U tubes, stress-relieved heat exchanger tube, pickled and passivated U tubes, DLSS stainless U tube manufacturer, 1.5D U bend tube, CuNi U bend tube ASTM B111, EN10204 3.2 certified U tubes

Conclusion

Specifying U-bend stainless steel tubes requires attention to material grade, bending parameters, wall thinning, and inspection requirements. Proper sourcing ensures long service life and system integrity under fluctuating thermal loads.

DLSS is an experienced manufacturer and exporter of U-bend tubes for global heat exchanger OEMs and EPC contractors.

Contact DLSS for Custom U-Bend Tube Solutions

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Let us help you engineer precision, performance, and peace of mind into your next heat exchanger project.