In recent years, Latin America has emerged as a hotbed of industrial investment. From deepwater oil fields in Brazil to lithium mines in Argentina and sugar mills in Colombia, the region is investing heavily in infrastructure and energy.

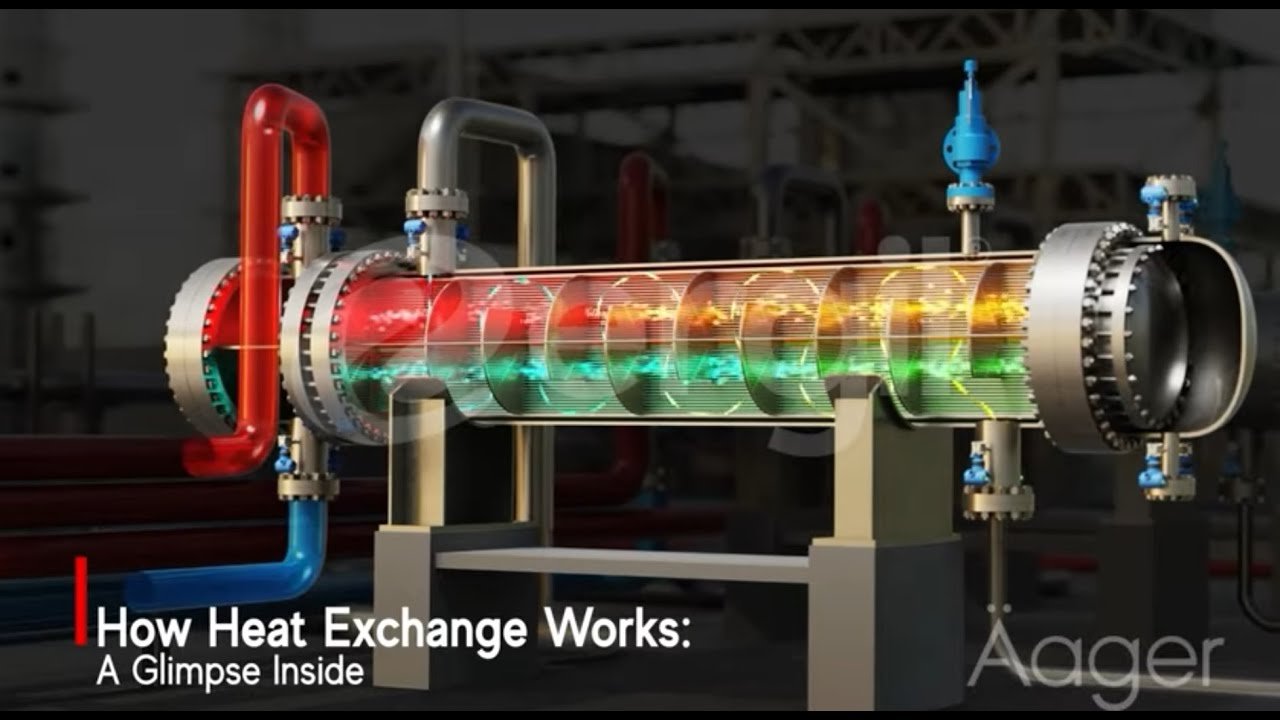

For suppliers of stainless steel tubes, heat exchanger coils, and industrial piping systems, this presents both a massive opportunity and a new set of challenges.

1. Where the Projects Are Coming From

Latin America is seeing diverse industrial growth across oil & gas, renewables, and heavy industry. Here are just a few highlights:

| Country | Key Projects | Materials Needed |

|---|---|---|

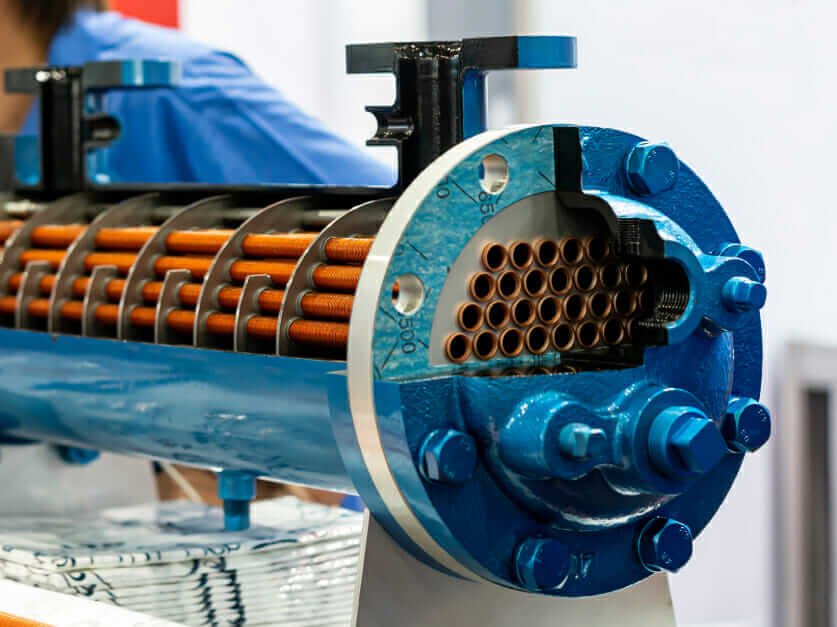

| Brazil | Petrobras offshore oil platforms, FPSOs | Duplex tubes, clad pipes, seawater-cooled heat exchangers |

| Argentina | Vaca Muerta shale development, lithium processing | Seamless pipes, high-pressure boiler tubes |

| Chile | Copper & lithium mining, desalination plants | Corrosion-resistant process tubing, pickled pipes |

| Colombia | Sugar & ethanol plant expansion | ASTM A249/A269 tubes for condensers, evaporators |

| Mexico | Refinery modernization (Pemex), natural gas pipelines | Large OD piping, elbows, flanges, ASTM A312 tubes |

Demand is particularly strong for ASME-certified, corrosion-resistant stainless steel tubing with tight tolerances and export-grade packaging.

2. What Latin American Buyers Expect

Buyers in the region—EPC contractors, plant owners, and industrial end users—have become more technical and selective. Price matters, but so do:

- Clear material documentation in English & Spanish (EN 10204 3.1/3.2)

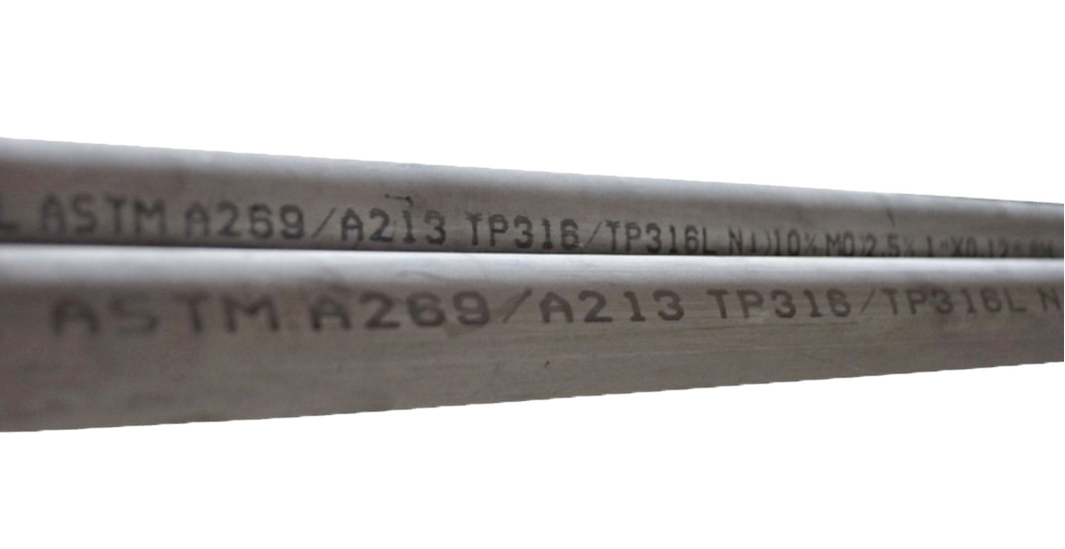

- Compliance with standards like ASME SA213, SA789, ASTM A312, A269

- Export readiness (fumigated wooden crates, markings, country-of-origin)

- Short lead times for shutdowns or brownfield upgrades

- Technical support, especially for custom U-tubes, finned tubes, or drawing specs

3. Challenges for Suppliers

Despite the opportunity, challenges include:

- Port delays in Brazil and Argentina → suppliers must offer early shipments or flexible Incoterms

- Import regulations and tariffs → accurate HS codes, certificates, and support from freight forwarders are key

- Language barrier → bilingual support or Spanish packaging list / invoices help win trust

- Payment terms & risk management → many buyers request net terms or part-payment after delivery; experience with trade insurance or LC is valuable

Suppliers who fail to meet compliance or documentation standards may face rejected shipments or long customs holds.

4. Success Factors: What Makes a Reliable Tube Supplier?

| Factor | Why It Matters |

|---|---|

| Product Range | From bright annealed tubes to heavy-wall duplex pipe—buyers want one-stop solutions |

| Certifications | ASME, ISO 9001, PED, and region-specific documents |

| Reference Projects | Especially for refineries, sugar plants, or mines |

| Flexible MOQ | Support for urgent or small-batch procurement |

| Pre-shipment inspection support | Many buyers require third-party checks before loading |

Frequently Asked Questions (FAQ)

Q1: What standards are most requested by Latin American EPCs?

A: ASME SA213/SA312, ASTM A269/A249, and EN10216-5 are commonly required. Most projects also request 3.1 MTC and export-ready packaging.

Q2: Are polished or pickled tubes preferred in the sugar & ethanol industry?

A: For heat exchangers and evaporators in sugar mills, ASTM A249 pickled tubes are common due to cost-effectiveness and corrosion resistance.

Q3: What types of pipes are used in lithium or copper mines?

A: Austenitic stainless steel (TP316L), or sometimes duplex grades, are preferred in corrosive brine or chemical environments. Pipes must withstand pressure, scaling, and corrosion.

Q4: How can a Chinese supplier stand out in Latin America?

A: Bilingual communication, flexible lead times, complete documentation, and reliable project case studies help build trust.

Conclusion: Local Mindset, Global Standards

Latin America may not have the same purchasing volume as the Middle East or Southeast Asia, but its project diversity, infrastructure investments, and growing technical sophistication make it a valuable market for stainless steel tube and pipe suppliers.

Manufacturers who combine certified products, logistical know-how, and customer-focused service are the ones best positioned to ride the next wave of industrial growth in the region.