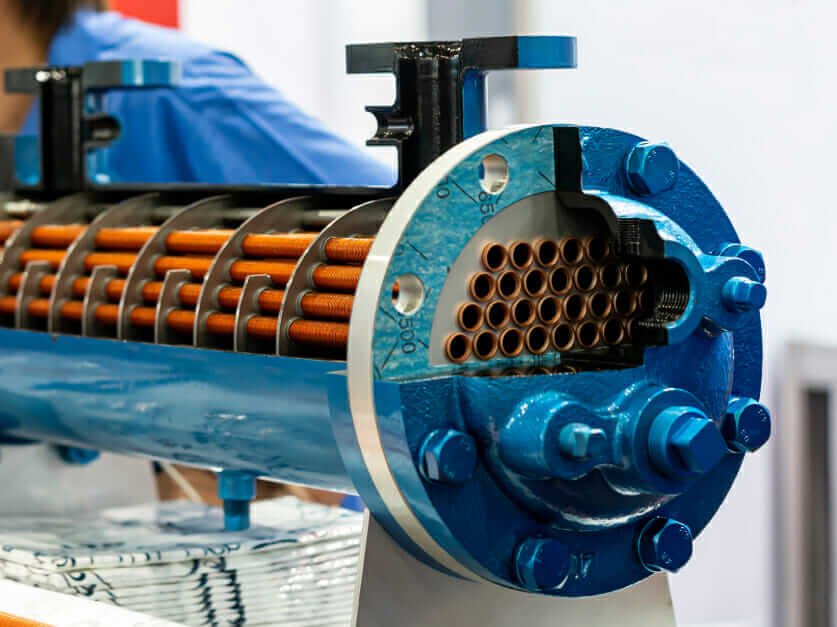

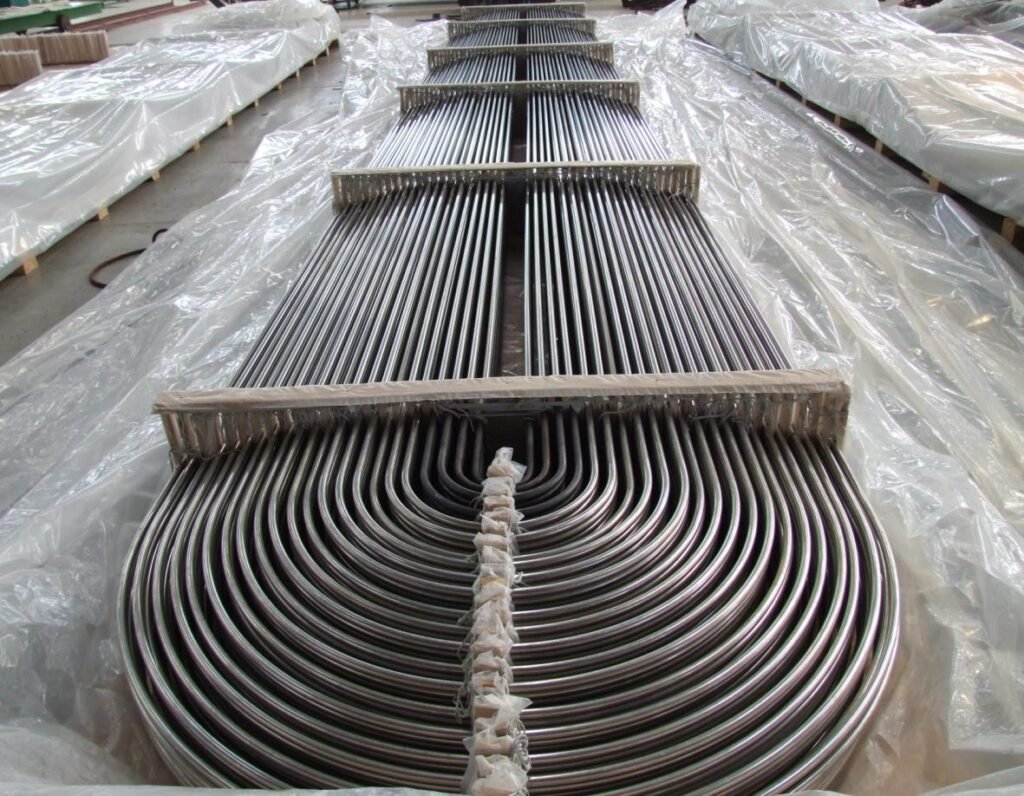

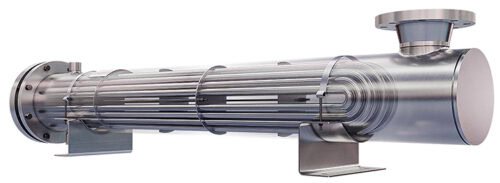

U-bent tubes are critical components in various heat exchanger systems, especially where space-saving or directional flow change is required—such as in shell-and-tube heat exchangers, condensers, boilers, and superheaters.

This article explains the manufacturing process, quality standards, and key applications of U-bent stainless steel tubes, along with how DLSS Pipeline ensures precision and reliability in every bend.

1. What Are U-Bent Tubes?

U-bent tubes are seamless or welded stainless steel tubes bent into a “U” shape using precision forming equipment. This design enables counterflow heat exchange within a compact space, making it ideal for high-efficiency and high-temperature systems.

Typical applications include:

- Shell-and-tube heat exchangers

- Condensers and evaporators

- Feedwater heaters and superheaters

- Waste heat recovery units

2. U-Bending Manufacturing Process

At DLSS, U-bent tubes are manufactured through a tightly controlled multi-step process:

Step 1: Pre-bend Preparation

- Tubes are cut to required length

- End faces are deburred and cleaned

- ID/OD are inspected for straightness and ovality

Step 2: Cold Bending

- Tubes are bent using mandrel-controlled precision U-bend equipment

- Bend radius typically ≥1.5×OD (or as per TEMA standard)

- No wrinkling, ovality, or wall thinning allowed

Step 3: Stress Relieving (Post-Bend Heat Treatment)

- Performed in inert gas or vacuum furnace

- Eliminates residual stress at bend area

- Required for most ASME/EN-certified exchangers

Step 4: Final Inspection and Packing

- Leg length, bend radius, and straightness are verified

- Dye penetrant or hydro test may be conducted

- Tube ends are capped, matched, and protected with separators

For custom U-bend inquiries, contact DLSS Pipeline

3. International Standards & Tolerances

DLSS produces U-bent tubes according to the following standards:

- ASME SA213 / SA789 – Seamless and welded tubes for boilers and heat exchangers

- EN 10216-5 / EN 10217-7 – Austenitic and duplex stainless steel pressure tubes

- TEMA R, C, and U classifications – Governing tolerances and bending guidelines

- PED 2014/68/EU, ISO 9001, and other client-specified standards

Typical tolerance controls:

- Leg length tolerance: ±1.5 mm

- Bend centerline radius: ±1.0 mm

- Ovality in bend: ≤10%

- Wall thinning: ≤12% (as per ASME)

4. Common Grades and Sizes Available

DLSS manufactures U-bent tubes in the following materials:

| Grade | Typical Use |

|---|---|

| TP304 / TP304L | General heat exchangers, HVAC |

| TP316 / TP316L | Chemical, food, marine environments |

| TP317L | Acidic fluids, high chloride environments |

| 2205 / S31803 | Offshore, pressure vessels |

| S32750 | Oil & gas, high-stress systems |

OD range: 12.7 mm – 38.1 mm

Wall thickness: 0.8 mm – 4.0 mm

Bend radius: 1.5×OD and above

U-leg length: Up to 12 meters (or custom)

5. Inspection and Quality Assurance

Each U-bent tube undergoes strict quality control:

- Visual & dimensional inspection for bend shape and tolerance

- Eddy Current Testing or Hydrostatic Testing

- Dye Penetrant Testing at bend zones

- Material certificate (EN 10204 3.1 or 3.2)

- Heat treatment record with time/temperature tracking

Learn more about DLSS inspection capabilities at www.dlsspipeline.com

Frequently Asked Questions (FAQ)

Q1: What’s the minimum bend radius for U-tubes?

Most common is 1.5×OD, but DLSS can provide tighter or custom radii upon request.

Q2: Is post-bend stress relieving always required?

Yes, especially for high-temperature or ASME Section I/III applications. It improves tube life and dimensional stability.

Q3: Can DLSS supply matched U-tube bundles?

Absolutely. DLSS can label, group, and package tubes in matching sets per drawing or TEMA layout.

Conclusion

U-bent stainless steel tubes are essential for compact, high-efficiency heat exchangers. With precise bending, reliable heat treatment, and strict quality control, they ensure maximum performance and safety.

DLSS Pipeline is your trusted source for custom U-bend solutions—delivering quality, compliance, and performance for projects worldwide.