As industrial applications become more extreme—whether due to high chloride content, elevated temperatures, or corrosive media—the demand for high-alloy stainless steel seamless tubes is rising sharply. Materials such as 904L, 2205 duplex, and 2507 super duplex are seeing significant adoption across oil & gas, chemical processing, desalination, and offshore energy sectors.

According to recent reports, these premium-grade materials are among the fastest-growing segments in the global stainless steel seamless tube market, as end-users shift from standard austenitic grades like TP304 and TP316L.

In this blog, we explore the market drivers, technical benefits, and application opportunities that are positioning high-performance stainless tube grades as strategic materials for the future.

1. Why Standard Austenitic Grades Are No Longer Enough

While TP304 and TP316L remain popular, they are often insufficient in high-chloride, acidic, or high-pressure environments. Failures caused by:

- Pitting and crevice corrosion

- Stress corrosion cracking (SCC)

- Weld decay or intergranular attack

- Fatigue under cyclic pressure/temperature

…are driving engineers toward more robust material alternatives.

2. High-Performance Grades in Focus

A. 904L (UNS N08904)

- Highly alloyed austenitic stainless steel

- Excellent resistance to sulfuric acid and chloride pitting

- Good weldability and formability

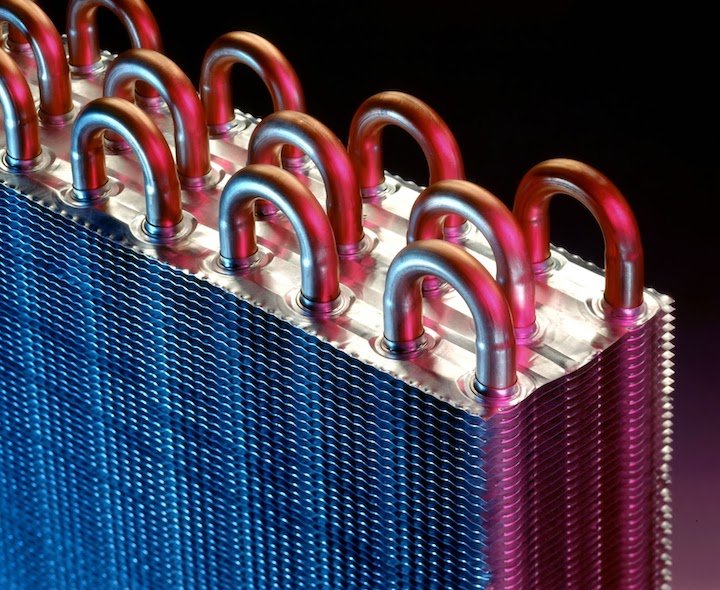

- Used in: acid plants, heat exchangers, condensers

B. 2205 Duplex (UNS S32205)

- Ferritic-austenitic structure = high strength + corrosion resistance

- Superior SCC and erosion resistance

- Lower nickel content = cost-effective

- Used in: offshore platforms, chemical plants, power generation

C. 2507 Super Duplex (UNS S32750)

- Very high PREN (>42) for severe chloride environments

- High mechanical strength = thinner wall possible

- Requires careful welding procedures

- Used in: seawater desalination, FPSOs, marine cooling

DLSS supplies 904L, 2205, and S32750 seamless tubes with full documentation and MTC. See: www.dlsspipeline.com

3. Market Sectors Demanding High-Alloy Tubes

| Sector | Key Use Cases | Tube Grades Commonly Used |

|---|---|---|

| Oil & Gas (onshore) | Sour gas, refinery condensers | 2205, 904L |

| Oil & Gas (offshore) | Cooling, injection lines, subsea exchangers | 2507, 2205 |

| Chemical Processing | Acid recovery, heat transfer | 904L, 317L |

| Desalination | Evaporators, condensing tubes | 2507, Titanium |

| Power Plants | Feedwater heaters, high-pressure preheaters | 2205, 2507 |

4. Market Trend: Duplex and Super Duplex Growing Faster than Austenitic

- Duplex tubes are growing at >7% CAGR globally

- 904L adoption rising in retrofitting and European projects

- OEMs and EPCs are specifying duplex grades for longer service life and reduced wall thickness

DLSS provides duplex and super duplex seamless tubes in compliance with ASME SA789, EN 10216-5, and PED requirements.

Frequently Asked Questions (FAQ)

Q1: Is 2205 a direct replacement for TP316L?

Not always. It offers superior performance, but welding, handling, and certification must be considered.

Q2: How does 904L compare to 316L in acidic service?

904L has better resistance to sulfuric, phosphoric, and acetic acids. It’s a better choice in chemical heat exchangers.

Q3: Does DLSS offer small batch production of special grades?

Yes. We support both bulk orders and project-specific quantities for 904L, 2205, and S32750 with short lead times.

Conclusion

As global industries face tougher chemical, thermal, and mechanical demands, high-alloy stainless steel seamless tubes are becoming essential for reliability and safety. Choosing the right grade can significantly reduce lifecycle cost, maintenance frequency, and system downtime.

DLSS Pipeline delivers certified 904L, duplex 2205, and super duplex 2507 tubes to global clients with full material traceability and performance guarantees.