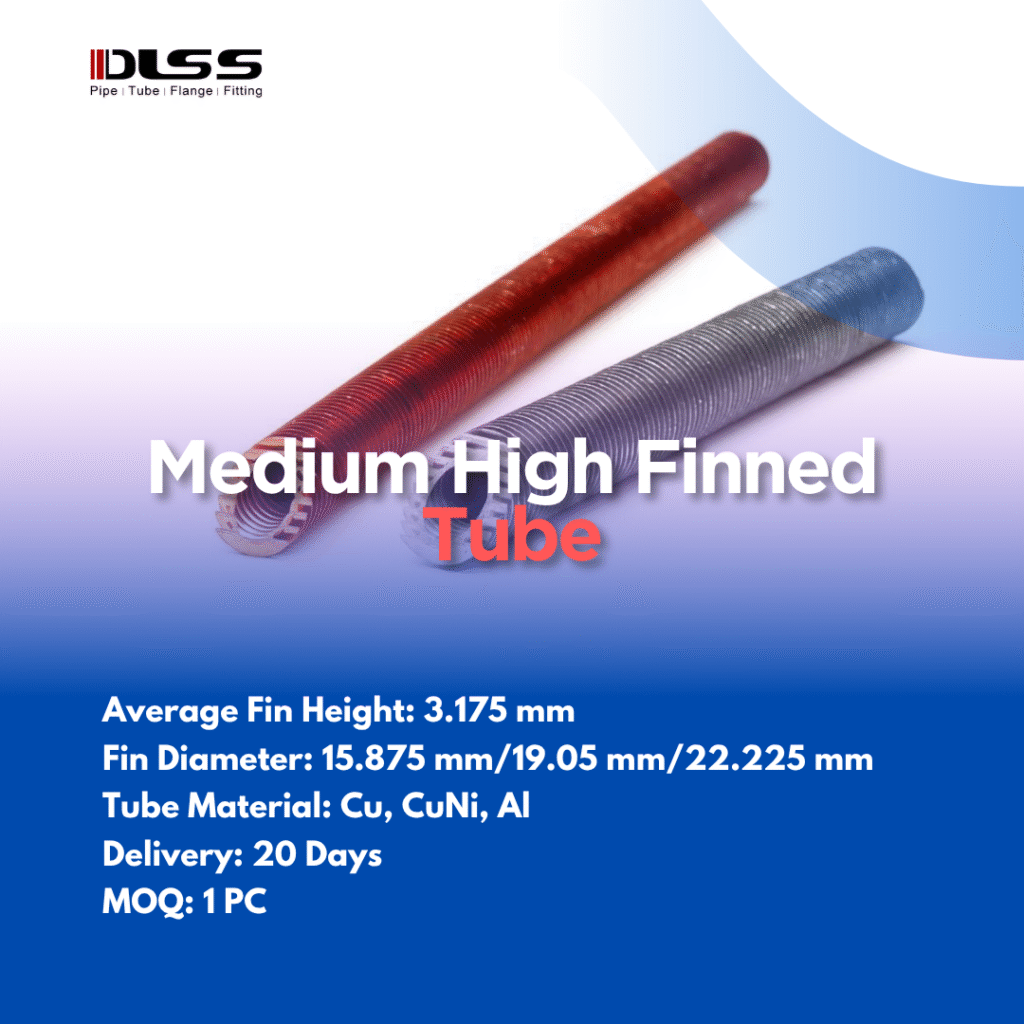

What Makes Our Finned tubes Stand Out for you?

Boost heat transfer efficiency by over 30% with our high-frequency welded finned tubes.

Custom fin designs available — spiral, serrated, L-type, and more.

Competitive pricing with high value – A cost-effective solution without compromising on quality or performance.

Flexible customization – Can be tailored in terms of fin type, material, tube diameter, and other specifications.

DLSS Finned tube

Product Cases

ASTM B151 C70600 Forged Elbow NPT

ASTM B151 C70600 forged elbow, NPT threaded, 3000# rating, ASME B16.11. CuNi 90/...

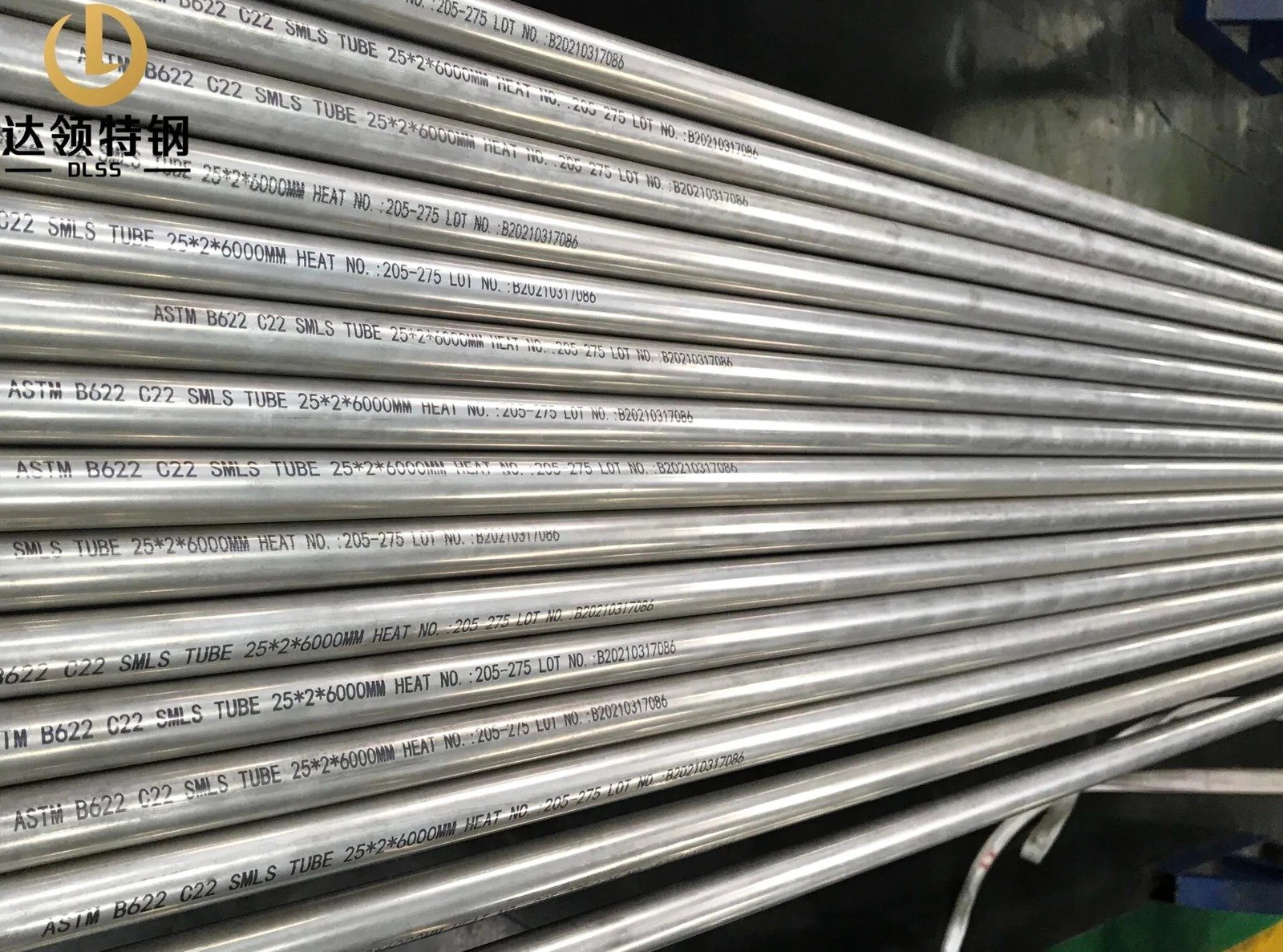

Read MoreASTM A269/A213 TP316/316L Seamless Tube 4×0.5MW×6000MM

ASTM A269/A213 TP316/316L seamless tube, 4×0.5×6000MM, bright annealed surface, ...

Read MoreASTM A815 WPS32205 Seamless 180° Bend

ASTM A815 WPS32205 seamless 180° bend, DN50 SCH10S, CD=143 mm, manufactured to A...

Read MoreASTM B729 Alloy 20 (UNS N08020)

ASTM B729 Alloy 20 (UNS N08020) seamless pipe, size 88.9×4.0×6000 mm, exported t...

Read MoreDifferentiated Services: Precisely Meeting Your Business Needs

for Stockists

for Heat exchanger manufacturers

for Traders

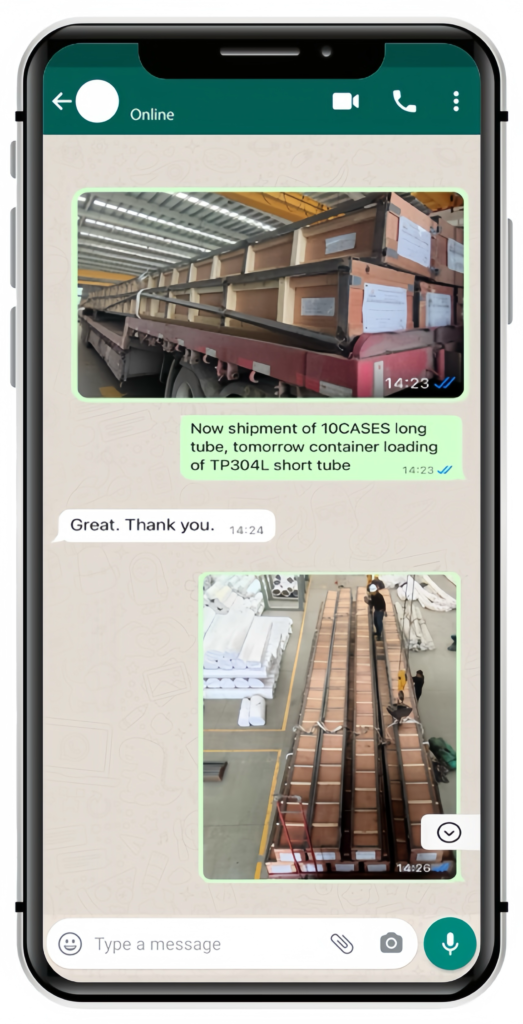

Fast Delivery

Efficient production and on-time delivery for your orders

Multiple Product Options

A wide range of Finned tubes to meet various project needs

Small Batch Logo Customization

Custom logos for small batch orders, enhancing your brand identity

Regional Pricing & Protection

Exclusive regional rights and strategic pricing to strengthen your market position

Cost-Effective Products

High-quality products at competitive prices to boost your margins

Flexible MOQ

Adaptable minimum order quantities to fit your business requirements

One-Stop Marketing Solutions

Boost your online image with a complete suite of product marketing visuals and videos

Fastest 7-Day Production Process

Delivery can be made within a minimum of 7 days based on your order size

Continuously upgraded packaging

We offer continuously upgraded packaging to ensure maximum protection and efficiency.

Are You Struggling With These Typical Finned tube Problems?

Frustrated by poor quality and inconsistent dimensions?

DLSS ensures consistent dimensions and quality by strictly controlling tube accuracy and conducting 100% inspections, preventing time and resource wastage.

Annoyed by cracks, porosity, and defects?

DLSS enforces strict quality control, with all products undergoing non-destructive testing to ensure defect-free and safe tubes, protecting the customer experience.

Frustrated by delayed deliveries?

DLSS has efficient production and supply chain management to ensure on-time delivery, even urgent orders can be completed on time, helping customers to advance their projects on time.

DLSS’s Core Principle: Never Leaving Problems For Clients

DLSS Partners

are you

A Distributor or Wholesaler?

Are You

an Engineer, Procurement Specialist, or Manufacturer?

Special for Broker

If you have connections with professionals in the heat exchanger, boiler, or industrial manufacturing industries.

We invite you to become a valuable partner with DLSS.

Company News

How to Choose the Right Hardness

Introduction Hardness testing is essential for verifyin […]

Read MoreHow to Choose the Right Pipe

Meta Description:Choosing pipe material can make or bre […]

Read MoreHow to Select the Right Stainless

Choosing the right tubing material is crucial for desig […]

Read MoreUnderstanding EN 10204 3.1 vs 3.2:

Meta Description:Learn the key differences between EN 1 […]

Read MoreWelcome To Send Us An Inquiry,

We Have Prepared A Surprise Gift For You