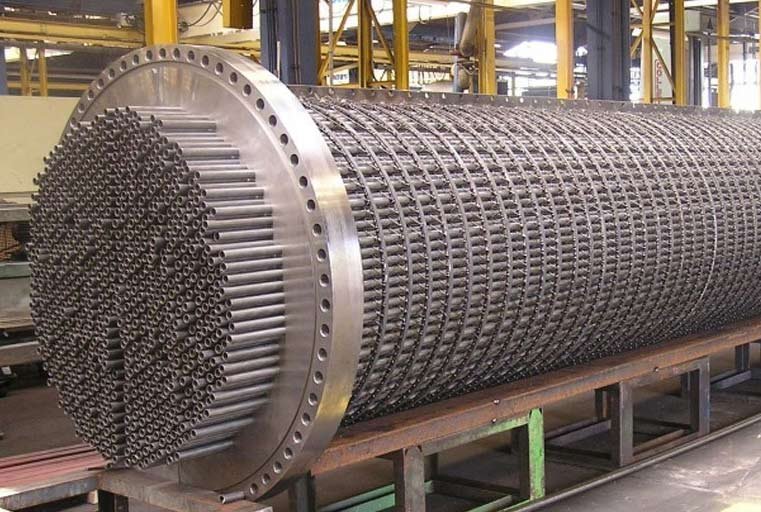

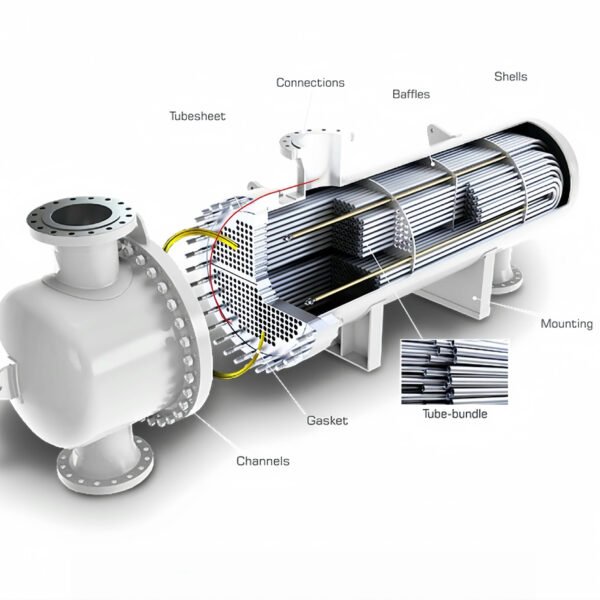

Heat exchanger tube failure can lead to system shutdowns, costly repairs, and even safety risks. Understanding the causes can help prevent future problems. In this article, we’ll cover the 5 most common reasons tubes fail—and how choosing the right materials and surface treatment can make all the difference.

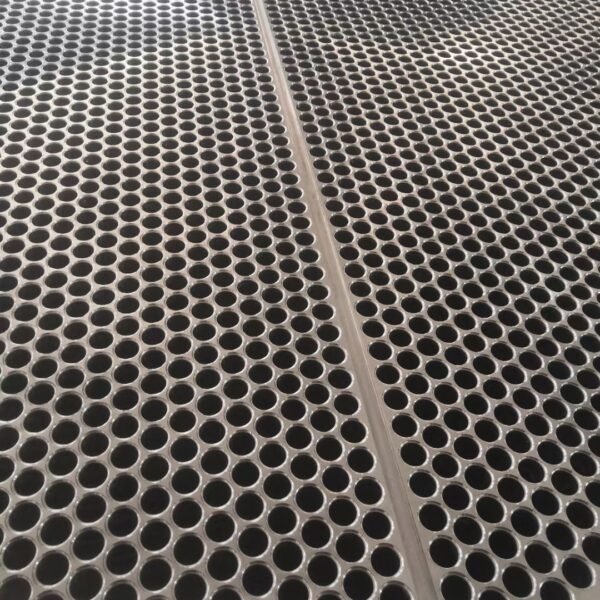

1. Pitting and Crevice Corrosion

Often caused by:

- Chlorides in water

- Inadequate surface cleaning

- Aggressive media accumulation in corners

Prevention: Use TP316L/317L stainless steel and pickled, smooth-surface tubes.

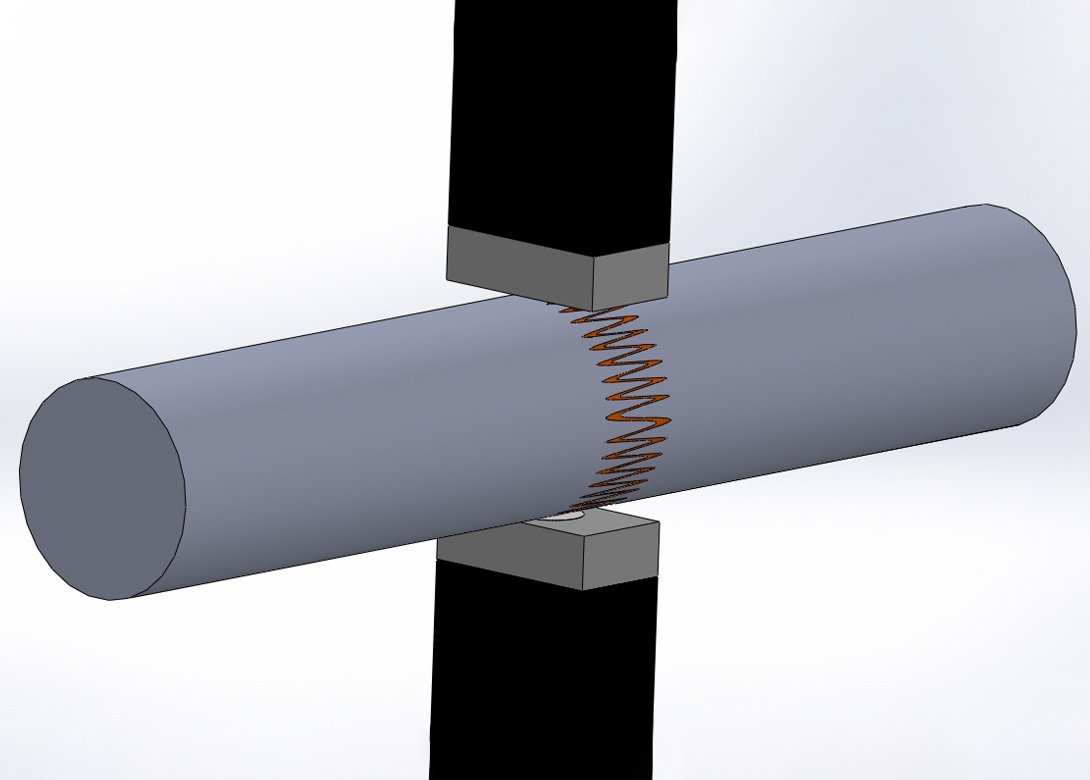

2. Thermal Fatigue and Stress Cracking

Due to:

- Rapid temperature fluctuations

- Poor expansion joint design

- Incompatible materials

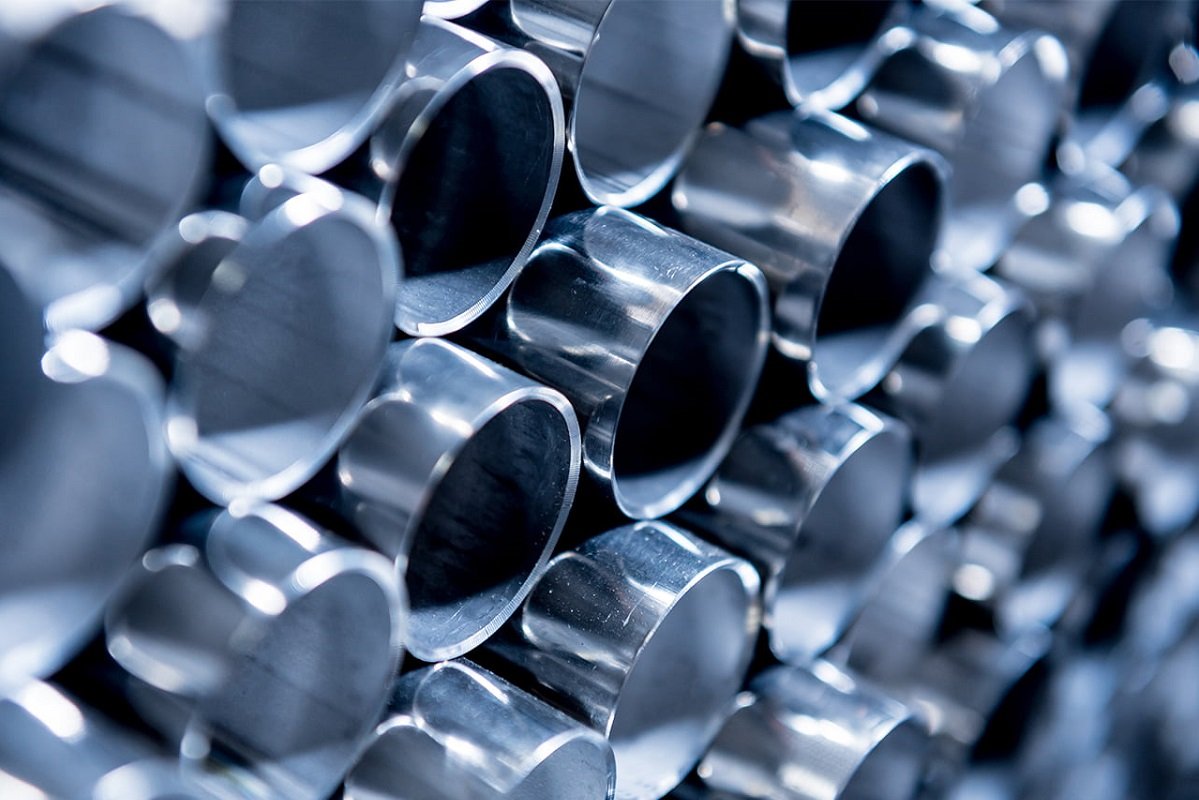

Prevention: Use low thermal expansion alloys and seamless tubes with high fatigue resistance.

3. Erosion from Turbulent Flow

Caused by:

- High flow velocities

- Solid particles in the media

- Poorly designed tube layout

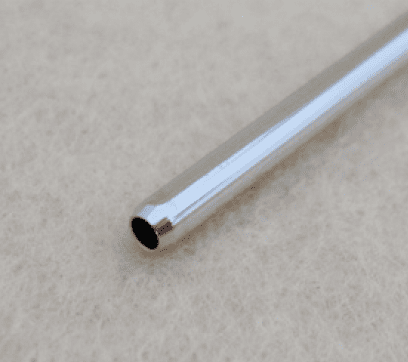

Prevention: Choose harder, thicker-walled stainless tubes with clean surface finishes.

4. Improper Material Selection

Wrong material = faster failure. For example:

- Copper in seawater

- Carbon steel in acidic media

Prevention: Always consult application conditions and choose corrosion-matched alloys.

5. Surface Contamination and Residues

Welding oxides or oil residues can trigger localized corrosion.

Prevention: Use pickled and passivated stainless steel tubes, like those from DLSS.

Final Thoughts

Many heat exchanger tube failures are preventable with smart design and material choices. At DLSS, we provide high-precision seamless stainless tubes that are pickled, inspected, and ready to perform.

Contact us today to learn how DLSS can help you reduce failure risks and boost system reliability.